Usinage CNC du titane : paramètres clés pour les pièces de précision

Introduction : le rôle décisif de l’optimisation des paramètres dans l’usinage de précision du titane

Dans le laboratoire d’usinage de précision de Neway, nous faisons chaque jour face au défi d’usiner une grande variété de composants en alliage de titane. En tant que matériau clé pour l’aéronautique, les dispositifs médicaux et d’autres industries de pointe, la qualité d’usinage des alliages de titane influe directement sur les performances et la fiabilité des produits finis. Après des années d’exploration pratique, nous avons compris qu’un contrôle précis des paramètres d’usinage est la clé pour atteindre un usinage haute précision des alliages de titane.

Dans nos services d’usinage CNC du titane, même de petits ajustements de paramètres individuels peuvent influer de manière significative sur les résultats d’usinage. De la durée de vie de l’outil et l’état de surface à l’efficacité d’usinage et à la précision dimensionnelle, tous les indicateurs de performance clés sont étroitement liés à la sélection des paramètres. En nous appuyant sur l’expérience d’ingénierie réelle de Neway, cet article explique de manière systématique les réglages de paramètres essentiels pour l’usinage de précision du titane.

Paramètre fondamental I : contrôle précis de la vitesse de coupe

Mécanisme de l’influence de la vitesse de coupe sur la durée de vie de l’outil et l’efficacité d’usinage

La vitesse de coupe est le facteur principal qui affecte les performances d’usinage. Lors de l’usinage du Ti-6Al-4V (TC4), nous réglons généralement la vitesse de coupe dans une plage de 30 à 50 m/min. Cette plage offre un bon équilibre entre efficacité d’usinage et durée de vie de l’outil. Des vitesses trop faibles intensifient l’écrouissage, tandis que des vitesses trop élevées entraînent une usure rapide de l’outil.

Nos nombreux essais montrent que lorsque la vitesse de coupe dépasse 60 m/min, l’usure par diffusion de l’outil augmente de manière significative. En effet, les alliages de titane deviennent plus chimiquement actifs à haute température et réagissent plus facilement avec les matériaux d’outil. C’est pourquoi, dans nos services d’usinage de précision, nous privilégions des vitesses de coupe relativement prudentes afin de garantir un usinage stable et fiable.

Plages de vitesses recommandées pour différents alliages de titane

Différents alliages de titane nécessitent des stratégies de vitesse spécifiques. Pour l’alliage de titane TC11, qui présente une résistance accrue à haute température, nous maintenons généralement les vitesses de coupe dans la plage de 25 à 40 m/min. Pour le Ti-6Al-4V ELI (Grade 23), nous pouvons augmenter modérément la vitesse à 35–55 m/min pour tirer parti de sa meilleure ténacité.

Évaluer la pertinence de la vitesse à travers la couleur et la forme des copeaux

Le comportement des copeaux est le « baromètre » du processus de coupe. Idéalement, les copeaux doivent être continus, en rubans argentés. L’apparition de copeaux bleus ou violets indique une température de coupe excessive et nécessite une réduction de la vitesse de coupe ou un refroidissement renforcé. Lors de l’usinage du Ti-10V-2Fe-3Al (Grade 19), nous accordons une attention particulière à la morphologie des copeaux et ajustons les paramètres en temps réel afin de maintenir des conditions de coupe optimales.

Paramètre fondamental II : réglage fin de l’avance

Relation intrinsèque entre l’avance par dent et la qualité de surface

L’avance influe directement sur la qualité de la surface usinée. En finition, nous réglons généralement l’avance par dent entre 0,02 et 0,08 mm/z. Elle doit être précisément associée à la vitesse de coupe pour atteindre la rugosité de surface souhaitée. Dans nos services d’usinage multi-axes, nous utilisons des stratégies CAM optimisées pour garantir une avance stable, même lors de l’usinage de surfaces complexes.

Application de stratégies à forte avance en ébauche

Pour l’ébauche, nous adoptons une stratégie « forte avance, faible profondeur ». L’avance par dent peut être portée à 0,1–0,2 mm/z, combinée à une profondeur de coupe de 2 à 3 mm. Cela garantit un taux élevé d’enlèvement de matière tout en maintenant les forces de coupe sous contrôle. Cette stratégie est particulièrement efficace lors de l’usinage de l’alliage de titane TA15, permettant une amélioration notable de l’efficacité.

Réalisation d’un contrôle de l’avance au micron en finition

Pour la finition ultra-précise, nous mettons en œuvre un contrôle de l’avance au niveau du micron. Grâce à des systèmes d’avance haute résolution, nous pouvons effectuer des ajustements aussi fins que 0,001 mm. Cette capacité est essentielle pour des composants tels que les implants médicaux, qui exigent une qualité de surface extrêmement élevée, nous permettant d’atteindre des rugosités inférieures à Ra 0,2 µm.

Paramètre fondamental III : choix stratégique de la profondeur de coupe

Co-optimisation des profondeurs de coupe axiale et radiale

La profondeur de coupe doit être définie en tenant compte à la fois des capacités de l’outil et de la rigidité de la machine. Nous utilisons généralement des profondeurs radiales inférieures à 50 % du diamètre de l’outil et des profondeurs axiales de 1 à 3 mm. Dans nos services de fraisage CNC, cette combinaison assure des conditions de coupe stables et une bonne qualité de surface.

Stratégies d’usinage par passes successives pour les cavités profondes

Pour l’usinage de cavités profondes, nous adoptons une approche par passes en profondeur successives (step-down). La profondeur de chaque passe est contrôlée à 2–3 mm, la dimension finale étant atteinte progressivement au fil de plusieurs passes. Lors de l’usinage du Ti-5Al-5V-5Mo-3Cr (Ti5553), cette stratégie permet d’éviter efficacement la surcharge de l’outil et de garantir la précision dimensionnelle.

Importance de la micro-profondeur de coupe pour les pièces à parois fines

Pour les pièces à parois fines, nous utilisons des coupes de très faible profondeur (0,1–0,5 mm) combinées à des vitesses d’avance plus élevées. Cela réduit considérablement les forces de coupe et permet de maîtriser efficacement la déformation. Pour les composants de structure aéronautique, cette technique nous permet d’usiner avec précision des épaisseurs de paroi pouvant descendre jusqu’à 0,5 mm.

Point clé I : adéquation précise entre choix de l’outil et géométrie

Sélection de matériaux d’outil et de revêtements spécialisés

Nous utilisons principalement des outils en carbure ultra-fin revêtus de couches AlTiN ou TiAlN. Dans nos services de tournage CNC, nous concevons des géométries d’outil dédiées pour différentes opérations : outils robustes pour l’ébauche et arêtes très tranchantes et précises pour la finition, afin de garantir une qualité de surface optimale.

Optimisation de l’angle de coupe, de dépouille et du rayon de bec

Une géométrie d’outil optimisée est essentielle pour obtenir des performances d’usinage optimales. Les configurations typiques incluent un angle de coupe positif de 6° à 10°, un angle de dépouille de 12° à 15° et un rayon de bec de 0,4 à 0,8 mm. Cette combinaison permet de préserver la résistance de l’outil tout en offrant de bonnes conditions de coupe. Lors de l’usinage de l’ alliage de titane Beta C, nous pouvons augmenter l’angle de coupe jusqu’à environ 12° pour améliorer encore la machinabilité.

Application de fraises à hélice variable et d’outils spéciaux pour le contrôle des vibrations

Pour les opérations sensibles aux vibrations, nous utilisons des fraises à pas et hélice variables ainsi que d’autres outils spécialisés. Leur conception à pas inégal perturbe les fréquences de résonance et améliore fortement la stabilité. Dans nos services d’usinage 5 axes, ces outils nous aident à atteindre un usinage à grande vitesse et haute qualité de surfaces complexes.

Point clé II : gestion efficace du fluide de coupe et de la température de coupe

Réglages critiques pour le refroidissement haute pression par arrosage à travers l’outil

Nous utilisons des systèmes de fluide de coupe haute pression avec arrosage par l’outil, fonctionnant à 70–100 bar, afin d’assurer un refroidissement efficace de la zone de coupe. Dans nos services de perçage CNC, le refroidissement haute pression réduit non seulement la température de coupe, mais améliore aussi grandement l’évacuation des copeaux. Nos essais montrent qu’à environ 80 bar, la durée de vie de l’outil peut augmenter de plus de 50 %.

Contrôle précis de la concentration, du débit et de l’angle de pulvérisation du fluide de coupe

Les paramètres du fluide de coupe doivent être rigoureusement contrôlés. Nous maintenons généralement la concentration dans la plage de 8 à 10 % et ajustons soigneusement les angles de pulvérisation afin de couvrir intégralement la zone de coupe. Dans nos services de rectification CNC, nous utilisons des fluides de rectification dédiés, formulés avec des additifs spécifiques pour prévenir le collage et le chargement de la meule lors de l’usinage des alliages de titane.

Scénarios d’application de l’air cryogénique et de la lubrification minimale (MQL)

Pour certaines opérations particulières, nous appliquons des systèmes de refroidissement par air froid ou la technologie MQL (Minimal Quantity Lubrication). Ces méthodes sont plus respectueuses de l’environnement et peuvent offrir d’excellents résultats dans des cas spécifiques. En particulier dans la fabrication de dispositifs médicaux, la MQL permet d’éviter les résidus de fluide de coupe et de répondre à des exigences strictes de biocompatibilité.

Point clé III : stratégie de trajectoire d’outil et suppression des vibrations

Principes de programmation pour le fraisage trochoïdal et l’interpolation hélicoïdale

Nous utilisons largement des trajectoires d’outil avancées telles que le fraisage trochoïdal et l’interpolation hélicoïdale. En maintenant une charge de coupe constante, ces stratégies améliorent considérablement la stabilité du procédé. Dans nos services d’usinage par décharge électrique (EDM), nous optimisons également les trajectoires des électrodes afin d’améliorer la qualité de surface et la précision dimensionnelle.

Évaluation et optimisation de la rigidité du système machine–montage–outil

La rigidité du système influe directement sur la précision d’usinage. Nous utilisons l’analyse modale pour évaluer les caractéristiques dynamiques, puis optimisons la conception des dispositifs de bridage et la sortie d’outil (porte-à-faux). Dans nos services de fabrication en petites séries, cette approche systématique permet une optimisation rapide et fiable des procédés.

Utilisation d’outils amortis et de systèmes de contrôle actif des vibrations

Pour les opérations fortement sujettes au broutement, nous employons des outils amortis et des systèmes de contrôle actif des vibrations. En surveillant et en compensant les signaux de vibration en temps réel, ces technologies permettent de supprimer efficacement le broutement. Dans le secteur des équipements industriels, elles contribuent à garantir l’usinage haute précision de composants critiques.

Point clé IV : ajustements ciblés selon l’état métallurgique du titane

Différences de paramètres selon les états métallurgiques

L’état métallurgique des alliages de titane a une influence significative sur le choix des paramètres. Nous conservons des tableaux de paramètres adaptés aux états recuit, traité par solution et vieilli. Les matériaux recuits peuvent être usinés avec des paramètres relativement plus agressifs, tandis que les matériaux vieillis nécessitent des réglages plus conservateurs.

Identification des variations entre lots et affinage des paramètres

Même au sein d’une même nuance, différents lots de matériau peuvent présenter des comportements variés. Nous avons mis en place un système de traçabilité complet pour enregistrer les paramètres d’usinage et les résultats correspondants pour chaque lot. Dans nos services de production de masse, ce niveau de détail garantit une qualité d’usinage constante sur de grandes séries.

Pratiques de Neway en matière d’optimisation des paramètres pour l’usinage de précision du titane

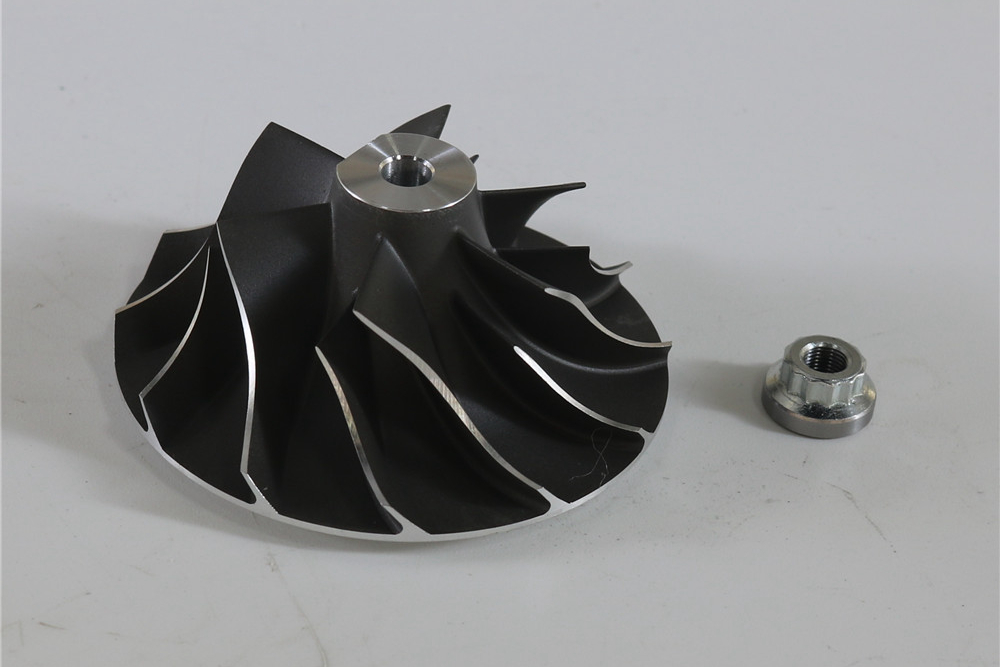

Dans le secteur de l’aéronautique, notre optimisation systématique des paramètres a permis de résoudre avec succès des défis d’usinage pour des composants critiques tels que des aubes de moteur. En maîtrisant précisément chaque paramètre, nous garantissons non seulement la précision dimensionnelle, mais aussi une intégrité de surface supérieure.

Notre cadre d’optimisation des paramètres repose sur de nombreuses données expérimentales et une analyse théorique approfondie. De l’ industrie automobile à la robotique, nous avons accumulé une riche expérience dans l’usinage du titane, ce qui nous permet de définir rapidement des jeux de paramètres optimaux pour de nouveaux projets.

Conclusion : une gestion systématique des paramètres comme fondement de l’usinage de précision du titane

Chez Neway, nous appliquons notre expertise en optimisation des paramètres à chaque projet via notre modèle de service intégré « one-stop ». Nous comprenons parfaitement que l’usinage de précision du titane est un défi d’ingénierie global, qui nécessite de prendre en compte de manière intégrée les propriétés du matériau, les performances de l’outil, les capacités de l’équipement et les exigences spécifiques de l’application.

En combinant nos services d’électropolissage et les traitements de micro-sablage, nous améliorons encore la qualité de surface et les performances fonctionnelles des composants en titane. La synergie entre des paramètres d’usinage précisément maîtrisés et des post-traitements avancés garantit que les pièces finales répondent aux exigences d’application les plus strictes.