Welche Toleranz- und Oberflächengüten sind beim CNC-Bearbeiten von Keramik erreichbar?

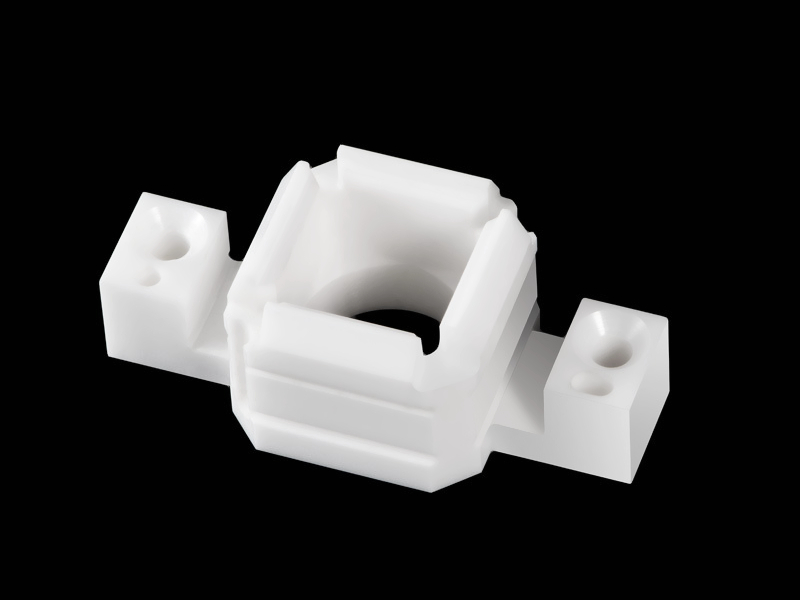

Keramische Werkstoffe gehören zu den anspruchsvollsten, aber auch lohnendsten Bereichen der Präzisionsbearbeitung. Sie erfordern spezielles Fachwissen und Ausrüstung, um optimale Ergebnisse zu erzielen. Bei Neway wurde unser CNC-Keramikbearbeitungsservice entwickelt, um außergewöhnliche Präzision und Oberflächenqualität bei einer Vielzahl fortschrittlicher keramischer Materialien zu liefern und deren Einsatz in anspruchsvollen Anwendungen in verschiedenen Branchen zu ermöglichen.

Toleranzfähigkeiten in der Keramikbearbeitung

Die spröde, nichtduktilen Eigenschaften von Keramiken stellen besondere Herausforderungen beim Einhalten enger Toleranzen dar, doch durch spezialisierte Prozesse erreichen wir bemerkenswerte Präzisionsniveaus.

Standard-Toleranzbereiche

Für die meisten keramischen Materialien liefern unsere Standardbearbeitungsfähigkeiten:

Maßtoleranzen: ±0,01 mm (±0,0004 Zoll) für kritische Abmessungen

Geometrische Toleranzen: Geradheit und Ebenheit innerhalb von 0,005 mm pro 25 mm (0,0002 Zoll pro Zoll)

Bohrungspositionstoleranzen: ±0,005 mm (±0,0002 Zoll) für präzise Bohrmuster

Konzentrizität: Innerhalb von 0,003 mm (0,0001 Zoll) bei rotierenden Komponenten

Diese Standards gelten für Materialien wie Aluminiumoxid (Al₂O₃) und Zirkonoxid (ZrO₂), bei denen unsere umfangreiche Erfahrung vorhersehbare und reproduzierbare Ergebnisse ermöglicht.

Erreichen von Hochpräzisionstoleranzen

Für Anwendungen, die außergewöhnliche Präzision erfordern, setzen wir erweiterte Prozesse ein, die Folgendes ermöglichen:

Ultrahohe Toleranzen: Bis zu ±0,002 mm (±0,00008 Zoll) für kritische Merkmale

Submikron-Oberflächenform: < 0,0005 mm für optische Flachheitsanforderungen

Durchmesserkontrolle: Innerhalb von 0,001 mm für Lagerflächen und Dichtkomponenten

Diese Fähigkeiten sind besonders wertvoll für Komponenten in der Medizintechnik, wo keramische Implantate und chirurgische Werkzeuge höchste Präzision erfordern.

Oberflächenqualitäten bei keramischen Komponenten

Die Oberflächenqualität keramischer Komponenten beeinflusst ihre Leistung erheblich, insbesondere hinsichtlich Verschleißfestigkeit, Korrosionsbeständigkeit und Eignung für biomedizinische Anwendungen.

Standardfähigkeiten für Oberflächenrauheit

Unsere Standardprozesse für die Keramikbearbeitung erreichen typischerweise:

Oberfläche nach der Bearbeitung: Ra 0,4–0,8 μm (16–32 μin) für strukturelle Anwendungen

Verbesserte bearbeitete Oberfläche: Ra 0,2–0,4 μm (8–16 μin) durch optimierte Parameter und Werkzeuge

Feinbearbeitete Oberflächen: Ra 0,1–0,2 μm (4–8 μin) für Anwendungen mit hoher Oberflächenintegrität

Erweiterte Oberflächenveredelungstechniken

Für Anwendungen, die außergewöhnliche Oberflächenqualität erfordern, setzen wir spezialisierte Veredelungsprozesse ein:

Präzisionsläppen und -polieren: Erreichen von Ra-Werten bis zu 0,025 μm (1 μin) für optische und Lageranwendungen

Laser-Mikrobearbeitung: Erzeugung kontrollierter Oberflächentexturen mit Ra-Werten zwischen 0,05–0,5 μm für spezielle funktionale Anforderungen

Diamantschleifen: Verwendung unseres CNC-Schleifdienstes mit Diamantwerkzeugen zur Erzielung gleichmäßiger Oberflächenrauheiten bis zu Ra 0,05 μm

Materialspezifische Leistungsunterschiede

Verschiedene keramische Materialien weisen unterschiedliche Bearbeitungseigenschaften auf, die erreichbare Toleranzen und Oberflächen beeinflussen.

Oxidkeramiken

Aluminiumoxid (Al₂O₃): Erreicht typischerweise Ra 0,2–0,6 μm mit Maßtoleranzen von ±0,01 mm

Zirkonoxid (ZrO₂): Hervorragende Bruchzähigkeit ermöglicht feinere Oberflächen (Ra 0,1–0,4 μm) und engere Toleranzen bis ±0,005 mm

Nichtoxidkeramiken

Siliziumnitrid (Si₃N₄): Siliziumnitrid-Komponenten erreichen typischerweise Ra 0,2–0,5 μm bei hoher Festigkeit

Siliziumkarbid (SiC): Siliziumkarbid kann auf Ra 0,3–0,8 μm bearbeitet werden, mit speziellen Prozessen für feinere Oberflächen

Aluminiumnitrid (AlN): Aluminiumnitrid erreicht Ra 0,4–0,8 μm bei hervorragender Wärmeleitfähigkeit

Kritische Faktoren, die die Präzision der Keramikbearbeitung beeinflussen

Konsistente Ergebnisse in der Keramikbearbeitung erfordern sorgfältige Beachtung mehrerer Schlüsselfaktoren:

Maschinenfähigkeiten

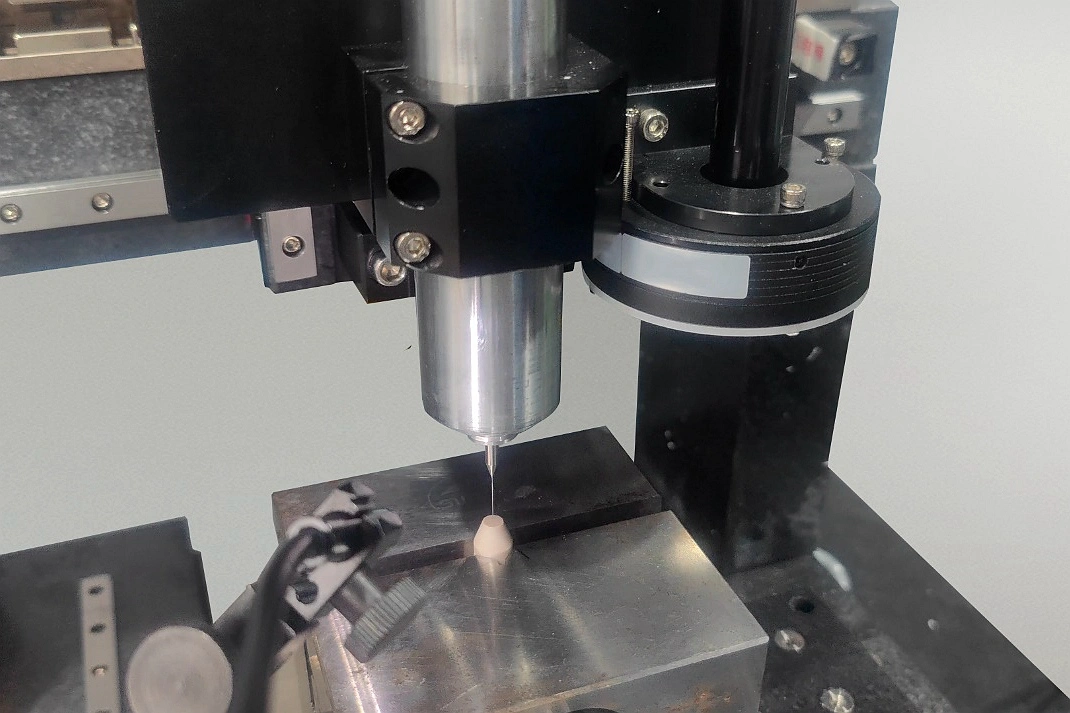

Hochsteife Maschinenplattformen: Minimierung von Vibrationen und Durchbiegungen durch starre Maschinenstrukturen

Fortschrittliche Steuerungssysteme: Präzise Bewegungssteuerung mit Submikronauflösung

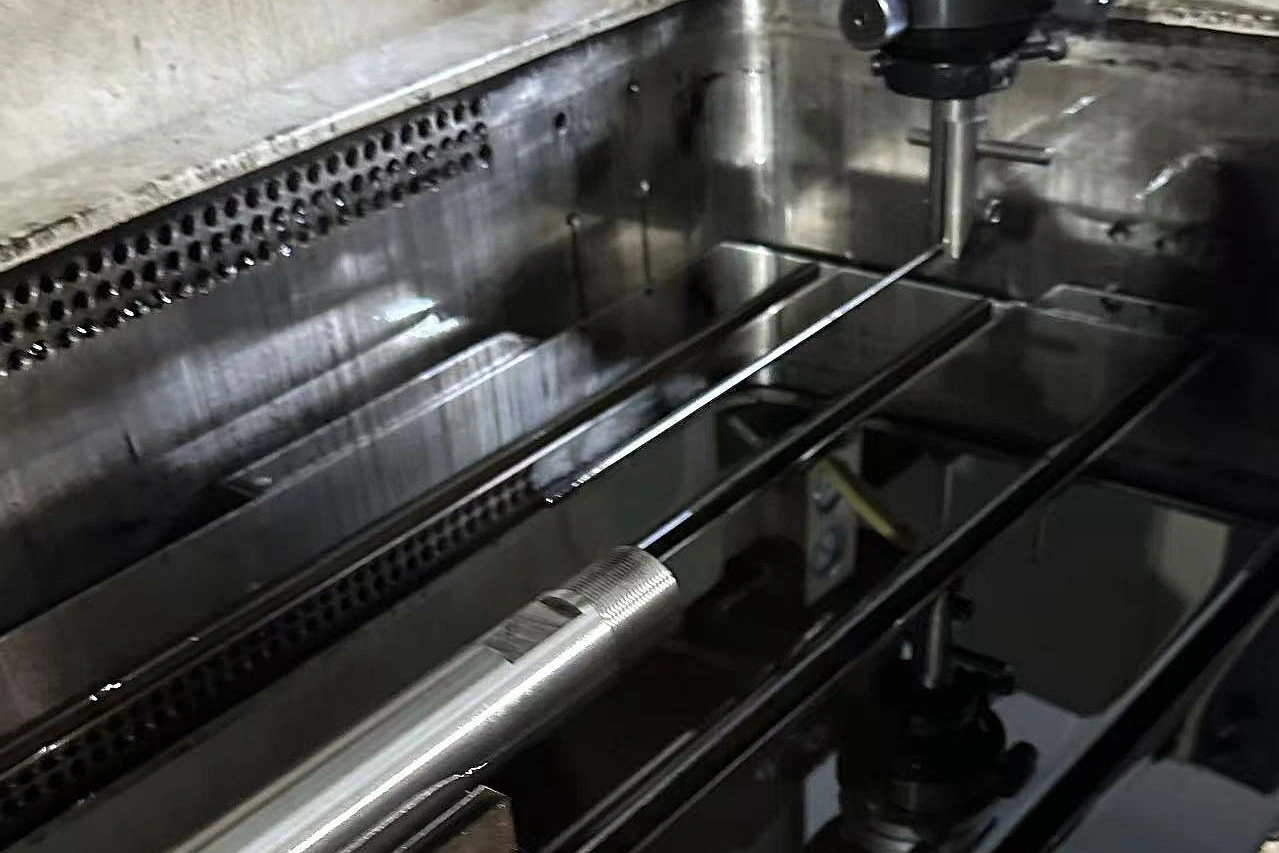

Thermische Stabilität: Aufrechterhaltung konstanter Temperatur, um Maßabweichungen zu vermeiden

Spezialisierte Werkzeuge: Mit Diamant beschichtete Werkzeuge, optimiert für keramische Materialien

Prozessoptimierung

Parameterentwicklung: Optimierte Schnittgeschwindigkeiten, Vorschübe und Schnitttiefen für jedes Keramikmaterial

Spannlösungen: Maßgeschneiderte Vorrichtungen, die spröde Materialien ohne Spannung fixieren

Kühlstrategien: Geeignete Kühlung und Schmierung zur Wärme- und Spanabfuhr

In-Prozess-Überwachung: Echtzeit-Feedback zur Erkennung potenzieller Probleme vor Qualitätsbeeinträchtigung

Qualitätssicherung und Verifizierung

Die Überprüfung der Qualität keramischer Komponenten erfordert spezialisierte Messtechniken:

Berührungslose Messung: Optische Vergleichssysteme und Bildverarbeitung zur Vermeidung von Oberflächenbeschädigungen

Fortschrittliche Oberflächenprofilometrie: 3D-Oberflächenanalyse zur Überprüfung von Ra-, Rz- und anderen Parametern

Formmessung: Prüfung von Rundheit, Ebenheit und Zylindrizität für kritische Merkmale

Materialintegritätstests: Mikroskopische Analyse zur Sicherstellung der Unversehrtheit unter der Oberfläche

Anwendungsspezifische Leistungsanforderungen

Verschiedene Branchen erfordern spezifische Kombinationen aus Toleranz und Oberflächengüte:

Medizinische und dentale Anwendungen

Keramische Komponenten für Medizinprodukte erfordern häufig:

Biokompatible Oberflächen: Ra < 0,2 μm zur Minimierung bakterieller Anhaftung und Gewebereizung

Präzise Passform: Toleranzen bis ±0,005 mm für implantierbare Komponenten

Hydrophile/Hydrophobe Kontrolle: Angepasste Oberflächenenergie für spezifische biologische Wechselwirkungen

Industrielle und Verschleißanwendungen

Komponenten für Industrieausrüstungen erfordern typischerweise:

Verschleißfeste Oberflächen: Kontrollierte Rauheit (Ra 0,4–0,8 μm) für optimale Schmierfilmhaftung

Maßstabilität: Toleranzen innerhalb ±0,01 mm für präzise Montage und Funktion

Thermisches Management: Erhalt der Materialeigenschaften durch kontrollierte Bearbeitung

Luft- und Raumfahrt- sowie Verteidigungskomponenten

Keramiken für Luft- und Raumfahrtanwendungen erfordern:

Hochtemperaturstabilität: Einhaltung der Toleranzen unter thermischen Zyklen

Erosionsbeständigkeit: Optimierte Oberflächen (Ra 0,2–0,5 μm) für aerodynamische Komponenten

Strukturelle Integrität: Überprüfung minimaler Suboberflächenschäden durch zerstörungsfreie Prüfmethoden

Dank unserer spezialisierten Expertise und kontinuierlichen Prozessverbesserung liefert Neway keramische Komponenten, die selbst die strengsten Anforderungen an Toleranz und Oberflächenqualität erfüllen und so die außergewöhnlichen Leistungsmerkmale moderner Keramiken in unterschiedlichsten Anwendungen ermöglichen.