Welche Innenflächenbehandlungen werden nach dem Tiefbohren zur Qualitätsverbesserung empfohlen?

Die Tieflochbearbeitung ermöglicht außergewöhnliche Funktionsmerkmale in Bauteilen, hinterlässt jedoch häufig spezifische Oberflächenzustände, die für eine optimale Leistung weiter verbessert werden müssen. Die Innenflächen von Tiefbohrungen stellen aufgrund ihres eingeschränkten Zugangs, hoher Längen-/Durchmesser-Verhältnisse und funktionaler Anforderungen besondere Herausforderungen für nachfolgende Behandlungen dar. Bei Neway empfehlen und implementieren wir mehrere spezialisierte Oberflächenbehandlungen, die gezielt für diese Herausforderungen entwickelt wurden und die Qualität, Leistung und Lebensdauer von Bauteilen mit Tiefbohrungen deutlich verbessern.

Grundlegende Reinigungs- und Vorbehandlungsprozesse

Bevor funktionelle Beschichtungen oder Oberflächenveredelungen aufgebracht werden, ist eine sorgfältige Vorbereitung der Innenfläche entscheidend, um Haftung und Performance sicherzustellen.

Fortschrittliches Entgraten und Reinigen

Der Tiefbohrprozess erzeugt zwangsläufig mikroskopische Grate und eingeschlossene Späne an der Bohrungsoberfläche. Wir begegnen dem durch:

Hochdruck-Ultraschallreinigung: Dieses Verfahren presst die Reinigungslösung über die gesamte Länge der Tiefbohrung und nutzt Ultraschallfrequenzen, um mikroskopische Partikel und Verunreinigungen zu lösen, die mit herkömmlicher Reinigung nicht entfernt werden können. Dies ist besonders wichtig für Komponenten in der Medizintechnik, wo partikuläre Verunreinigungen unzulässig sind.

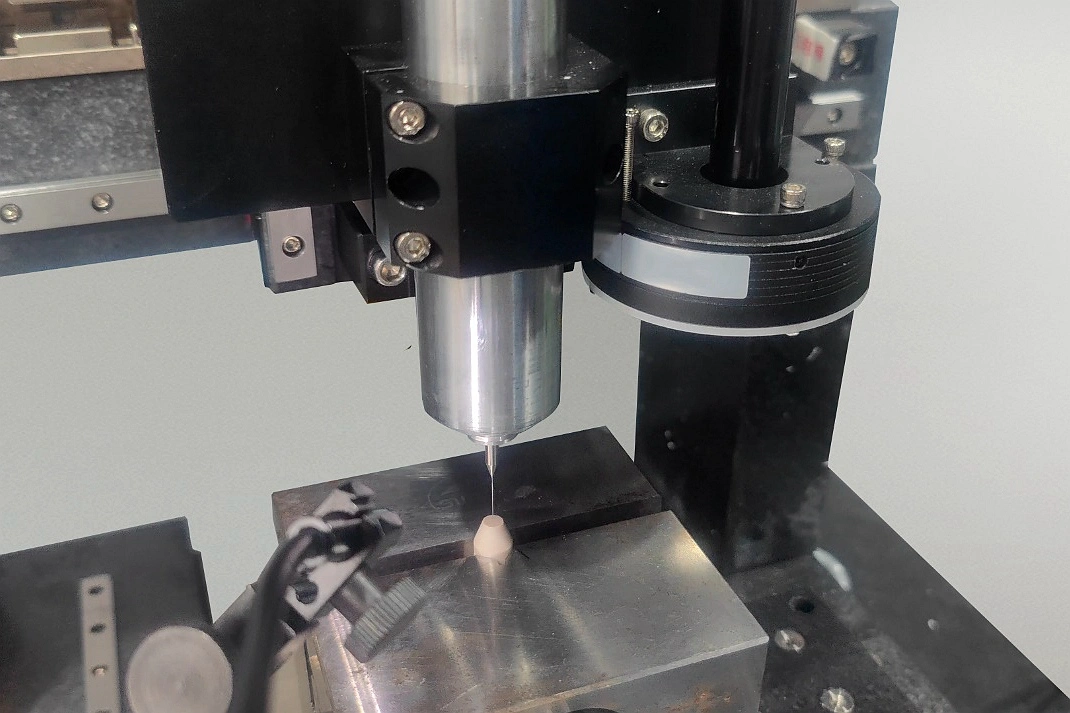

Abrasive Flow Machining (AFM): Für Anwendungen, die höchste innere Oberflächengüte erfordern, setzen wir AFM ein, bei dem ein viskoses, abrasives Medium unter Druck durch die Tiefbohrung gepumpt wird. Dieser Prozess entfernt Grate gleichmäßig, verrundet Kanten und kann die Oberflächengüte um bis zu zwei Klassen verbessern.

Verfahren zur Glättung von Innenoberflächen

Die Erzielung einer optimalen Oberflächentopografie im Inneren von Tiefbohrungen reduziert Reibung, verbessert den Medienfluss und erhöht die Ermüdungsbeständigkeit.

Elektropolieren für Präzisionsteile: Das Elektropolieren ist für Innenflächen besonders effektiv, da es eine dünne Materialschicht durch elektrochemische Auflösung entfernt und dabei bevorzugt mikroskopische Spitzen und scharfe Kanten angreift. Dieser Prozess kann die Oberflächenrauheit typischerweise um 50 % oder mehr verbessern und bildet gleichzeitig eine passive Schicht auf Edelstählen, die die Korrosionsbeständigkeit erhöht.

Innenhonen: Für Anwendungen, die präzise Maßhaltigkeit und Oberflächenverbesserung erfordern, setzen wir Innenhonen ein. Dabei werden Schleifsteine gegen die Bohrungsoberfläche expandiert. So entsteht ein idealer Kreuzschliff für Ölhaltevermögen in Hydraulikkomponenten bei gleichzeitiger Einhaltung enger Toleranzen.

Funktionelle Beschichtungen für gesteigerte Performance

Je nach Anwendungsanforderung empfehlen wir verschiedene Beschichtungstechnologien, die speziell an Innenflächen angepasst sind.

Verschleißfeste Innenbeschichtungen

Für Bauteile, die intern durch bewegte Teile oder abrasive Medien beansprucht werden:

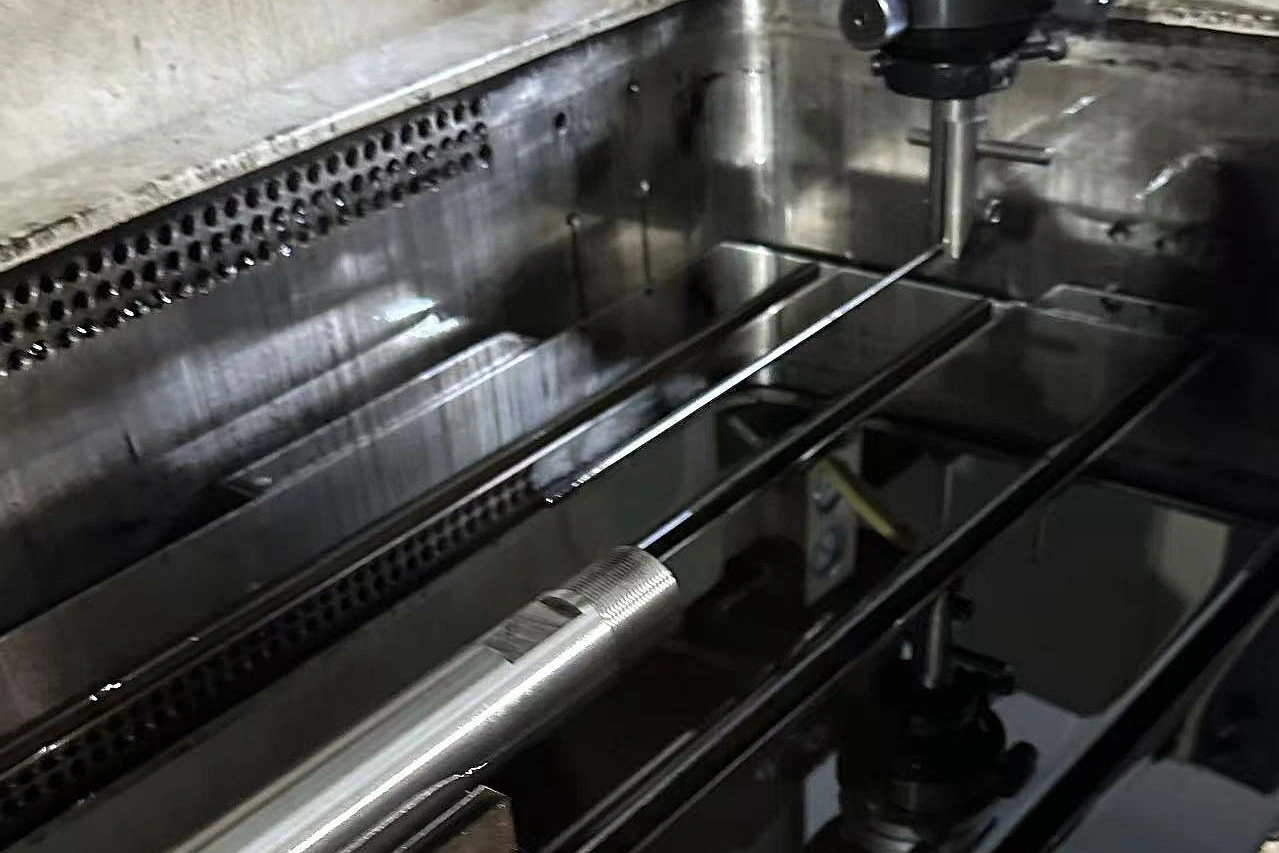

Galvanische Beschichtung für CNC-Teile: Interne Galvanikprozesse können Hartchrom oder andere verschleißbeständige Schichten auf die Bohrungsoberfläche aufbringen. Wir verwenden speziell angepasste Anoden und Lösungsturbulenz, um eine gleichmäßige Schichtdicke über die gesamte Tiefe sicherzustellen und so die Lebensdauer von Hydraulikzylindern und ähnlichen Komponenten deutlich zu verlängern.

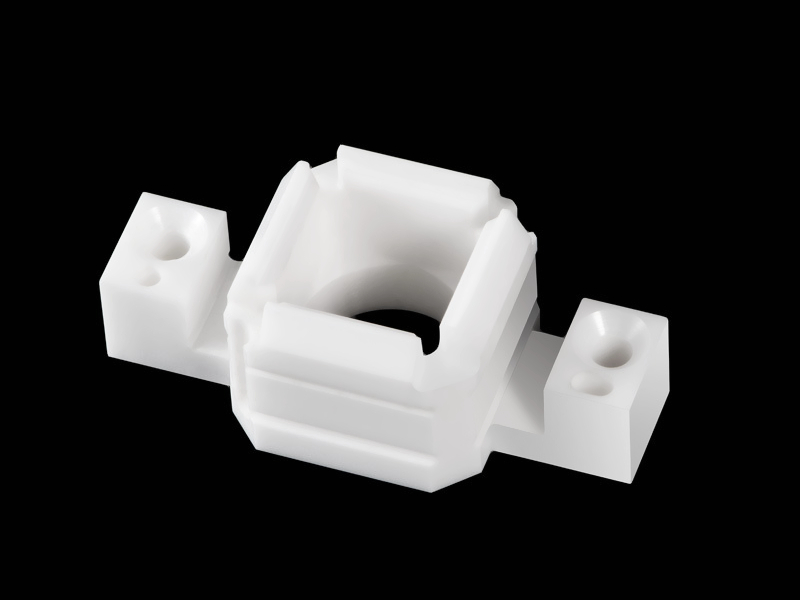

PVD-Beschichtung für Präzisions-CNC-Teile: Obwohl Innenflächen traditionell eine Herausforderung für PVD darstellen, haben wir Spannkonzepte und Prozessparameter entwickelt, die es ermöglichen, PVD-Beschichtungen auch in schwer zugänglichen Tiefbohrungen aufzubringen. Diese dünnen, harten Schichten bieten exzellente Verschleiß- und Reibungsreduzierung bei minimalem Einfluss auf die Maße.

Korrosionsbeständige Innenbehandlungen

Der Schutz der Innenflächen vor Korrosion ist in vielen Anwendungen kritisch:

Passivierung für Edelstahl: Die Edelstahl-Passivierung ist für Edelstahlkomponenten nach Tiefbohrbearbeitung essenziell, um die schützende Oxidschicht wiederherzustellen, die beim Zerspanen beeinträchtigt worden sein kann. Unser Prozess stellt eine vollständige chemische Behandlung über die gesamte Länge der Bohrung sicher.

Chemisch Nickel (stromlos): Dieser autocatalytische Prozess bringt eine gleichmäßige Nickel-Phosphor-Legierung auf allen Innenflächen auf – unabhängig von der Geometrie. Er bietet hervorragenden Korrosionsschutz und moderaten Verschleißschutz. Der Prozess folgt aufgrund seiner Chemie natürlich dem Verlauf der Tiefbohrung und ist nicht von der „Wurfweite“ wie bei elektrolytischen Verfahren begrenzt.

Werkstoffspezifische Empfehlungen für Innenbehandlungen

Die optimale Innenbehandlung hängt stark vom Grundwerkstoff und der Einsatzumgebung ab.

Aluminiumkomponenten

Für Bauteile aus der CNC-Bearbeitung von Aluminium mit Tiefbohrungen:

CNC Aluminium-Anodisierungsservice: Das Hart-Anodisieren erzeugt eine dicke, verschleißfeste Oxidschicht auf inneren Aluminiumoberflächen. Wir haben unsere Prozesse so optimiert, dass mit speziellen Kathodenanordnungen und Lösungsturbulenz eine vollständige Anodisierung in Tiefbohrungen gewährleistet ist.

Alodine-Beschichtung für Aluminium-CNC-Teile: Wenn die Maßstabilität besonders kritisch ist, bietet die Alodine-Beschichtung hervorragenden Korrosionsschutz bei minimaler Maßänderung. Sie ist ideal für Präzisionskomponenten in der Luft- und Raumfahrt.

Stahl- und Legierungskomponenten

Für Bauteile aus der CNC-Bearbeitung von Kohlenstoffstahl und Hochleistungslegierungen:

Schwarzoxid-Finish für CNC-Stahlteile: Die Schwarzoxid-Beschichtung erzeugt ein attraktives schwarzes Finish mit gutem Korrosionsschutz und minimalem Einfluss auf die Maße. Unsere Prozessführung stellt eine vollständige Behandlung der Innenflächen durch spezielle Aufhängung und Lösungsumwälzung sicher.

CNC-Stahl-Nitrierprozess: Für maximale Verschleißbeständigkeit an Innenflächen diffundiert das Nitrieren Stickstoff in die Stahloberfläche, ohne die Abmessungen zu verändern. Dies ist besonders wertvoll für Komponenten in der Öl- und Gasindustrie, in der sowohl Korrosions- als auch Verschleißbeständigkeit entscheidend sind.

Spezialisierte Behandlungen für extreme Anwendungen

Für Bauteile, die in besonders anspruchsvollen Umgebungen eingesetzt werden, empfehlen wir fortgeschrittene Behandlungsmethoden.

Beschichtungen für Thermomanagement

Für Komponenten in Hochtemperaturanwendungen:

Wärmeschutzbeschichtung für CNC-Komponenten: Wir können spezielle Thermal-Barrier-Coatings auf Innenflächen aufbringen. Durch proprietäre Applikationstechniken stellen wir eine gleichmäßige Schicht in Tiefbohrungen sicher und schützen das Grundmaterial vor extremen Temperaturen, beispielsweise in der Energieerzeugung.

Antihaft- und Reibungsminimierungs-Beschichtungen

Für Anwendungen, bei denen Anhaftungen vermieden oder Reibung minimiert werden muss:

Teflon-Beschichtung für CNC-Anwendungen: Eine interne Teflon-Beschichtung bietet hervorragende Antihaft-Eigenschaften und chemische Beständigkeit. Unser Prozess gewährleistet eine vollständige Abdeckung von Tiefbohrungen mit gleichmäßiger Schichtdicke – ideal für Anwendungen in der chemischen Verarbeitung und in Lebensmittelanlagen.

Implementierungsaspekte für Innenbehandlungen

Die erfolgreiche Anwendung dieser Behandlungen auf Tiefbohrungen erfordert spezielle Expertise und Ausrüstung:

Vorrichtungskonstruktion: Wir entwickeln kundenspezifische Vorrichtungen, die sicherstellen, dass Behandlungsmedien und Beschichtungen alle Innenflächen gleichmäßig erreichen.

Prozessvalidierung: Wir überprüfen die Wirksamkeit der Behandlung durch Endoskopie, Querschliffe an Musterteilen und funktionale Prüfungen.

Qualitätssicherung: Wir setzen strenge Qualitätsprüfungen ein, einschließlich Haftfestigkeitsprüfungen, Schichtdickenmessung und korrosionsspezifischer Tests für Innenflächen.

Durch die Auswahl und Anwendung geeigneter Innenoberflächenbehandlungen nach der Tieflochbearbeitung steigern wir die Leistung, Zuverlässigkeit und Lebensdauer von Bauteilen in allen von uns bedienten Branchen – von der Automobilindustrie über die Medizintechnik bis hin zu Luft- und Raumfahrtanwendungen.