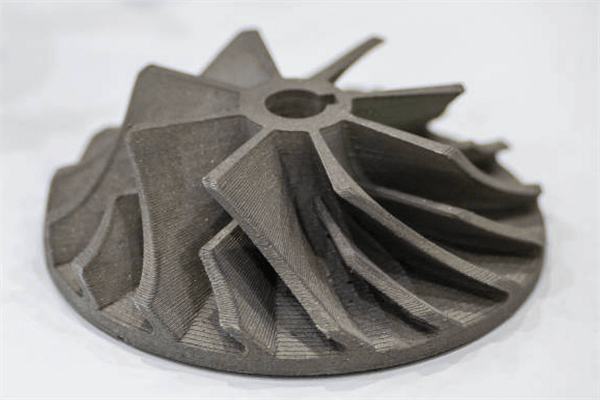

Service d’impression 3D Inconel : frittage sélectif par laser métal (DMLS)

Introduction : quand les superalliages rencontrent la fabrication additive

Dans la fabrication haut de gamme, les superalliages Inconel sont particulièrement appréciés pour leurs performances exceptionnelles sous des températures, des pressions et des environnements corrosifs extrêmes, ce qui en fait des matériaux de base dans les industries aéronautique, énergétique et de production d’électricité. Cependant, les caractéristiques mêmes qui rendent l’Inconel si performant — haute résistance mécanique, excellente tenue à chaud et forte tendance à l’écrouissage — le rendent également extrêmement difficile à usiner par des procédés soustractifs classiques comme l’usinage CNC. Les difficultés typiques comprennent une usure sévère des outils, des taux de rebut matière élevés et la difficulté à obtenir des géométries complexes. Heureusement, le développement rapide de la fabrication additive a apporté une percée. Parmi ces technologies, le frittage laser direct de métal (DMLS, Direct Metal Laser Sintering) révolutionne la production de pièces Inconel haute performance grâce à une liberté de conception inégalée.

Qu’est-ce que l’Inconel et pourquoi est-il difficile à usiner ?

L’Inconel est essentiellement un superalliage à base de nickel-chrome qui forme, à haute température (généralement au-dessus de 600 °C), une couche d’oxyde de chrome dense et fortement adhérente. Cette couche confère une résistance exceptionnelle à l’oxydation, à la corrosion et à la fatigue thermique. Dans les projets industriels de Neway, l’Inconel 718 et l’Inconel 625 sont les deux matériaux les plus couramment utilisés pour l’impression 3D. Le premier est apprécié pour sa très grande résistance mécanique à chaud, sa bonne soudabilité et sa résistance à la fatigue, ce qui en fait un matériau idéal pour les rotors de moteur. Le second est réputé pour son excellente résistance à la fatigue, au fluage et à la corrosion, et est largement utilisé pour des composants structuraux marins.

Cependant, ces propriétés exceptionnelles rendent l’Inconel extrêmement difficile à usiner par des services d’usinage CNC de superalliages classiques. Sa forte tendance à l’écrouissage provoque un durcissement rapide du matériau pendant la coupe, ce qui réduit drastiquement la durée de vie des outils. Par ailleurs, sa conductivité thermique relativement faible limite l’évacuation de la chaleur : celle-ci s’accumule à l’interface outil-pièce, accélérant encore l’usure de l’outil et pouvant entraîner une déformation de la pièce.

Technologie DMLS (Direct Metal Laser Sintering) expliquée

Le DMLS est une technologie de fabrication additive métallique par fusion sur lit de poudre. Elle ne nécessite ni moule traditionnel ni outil de coupe. À partir des données CAO 3D, la pièce métallique dense est construite directement, couche par couche, grâce à un laser fibre de forte puissance qui fait fondre sélectivement la poudre métallique.

Le flux de travail précis peut se résumer ainsi : tout d’abord, le modèle 3D est « slicé » (découpé en couches) et les structures de support nécessaires sont conçues. Ensuite, dans une chambre de fabrication étanche, la plaque de base est préchauffée et l’atmosphère est remplie d’un gaz inerte (comme l’argon) pour éviter l’oxydation à haute température. Une racle ou un rouleau dépose une couche très fine de poudre Inconel sur la plaque de base. Le laser vient ensuite balayer la géométrie de la section courante, en faisant fondre complètement la poudre et en la soudant à la couche déjà solidifiée. Une fois la couche terminée, le plateau de fabrication s’abaisse de l’épaisseur d’une couche, et le cycle de dépôt et de balayage se répète jusqu’à ce que la pièce soit entièrement construite. La pièce imprimée brute doit généralement subir plusieurs étapes de post-traitement, notamment une séparation de la plaque de base par électro-érosion à fil, le retrait des structures de support, puis un traitement thermique critique pour soulager les contraintes résiduelles et optimiser les propriétés du matériau.

Cinq avantages clés du choix de l’Inconel en DMLS

Liberté de conception quasi illimitée : le DMLS rompt complètement les contraintes de conception de la fabrication traditionnelle, permettant de produire facilement des pièces avec des canaux de refroidissement internes conformes, des structures treillis allégées et des parois minces complexes. Les ingénieurs bénéficient ainsi d’une flexibilité sans précédent pour optimiser les fonctionnalités.

Intégration fonctionnelle et allègement : avec le DMLS, des ensembles initialement constitués de plusieurs composants peuvent être repensés et fabriqués sous forme de pièce monobloc. Cela réduit le nombre d’éléments de fixation et d’opérations d’assemblage, diminue les risques de défaillance et permet un allègement extrême via l’optimisation topologique tout en conservant la résistance requise.

Excellentes performances matériaux : sous des paramètres de procédé optimisés, les pièces Inconel produites par DMLS peuvent atteindre une densité de 99,8 % ou plus. Leur microstructure fine et homogène permet d’obtenir des propriétés mécaniques — résistance à la fatigue, résistance au fluage, etc. — comparables, voire supérieures, à celles de pièces issues de la fonderie ou de la forge conventionnelle.

Réduction significative des déchets et meilleure utilisation de la matière : contrairement aux méthodes soustractives classiques comme les services de fraisage CNC, où la majeure partie de la matière de départ est enlevée sous forme de copeaux, le DMLS est un procédé proche du « net shape ». La poudre non fondue peut généralement être récupérée, tamisée et réutilisée, ce qui se traduit par une utilisation de matière très élevée. Pour des alliages Inconel coûteux, cela représente des économies substantielles.

Prototypage plus rapide et mise sur le marché accélérée : le DMLS permet de transformer rapidement des modèles CAO en pièces métalliques fonctionnelles, réduisant significativement les cycles de développement et d’itération produits. Il est particulièrement adapté aux prototypes complexes difficiles ou non rentables à réaliser par prototypage par usinage CNC, aidant ainsi les produits à gagner un avantage concurrentiel en termes de « time-to-market ».

Étapes clés de post-traitement pour les pièces Inconel DMLS

L’achèvement de la fabrication DMLS ne représente que la moitié du chemin : un post-traitement approprié est indispensable pour atteindre les performances et la qualité finales visées.

Retrait des supports et nettoyage de surface : les pièces sont généralement séparées de la plaque de base par électro-érosion à fil (wire EDM). Ensuite, des procédés tels que le tumbling et l’ébavurage de pièces CNC sont utilisés pour retirer les structures de support, nettoyer la surface et ébavurer, en éliminant la poudre adhérente et les arêtes vives.

Traitement thermique critique : pour les alliages durcissables par précipitation tels que l’Inconel 718, le traitement de solution et le revenu de vieillissement — par exemple via le traitement thermique pour pièces usinées CNC — sont indispensables. Ces étapes permettent de soulager les contraintes résiduelles et de favoriser la précipitation des phases de durcissement afin de garantir que la pièce atteigne les propriétés mécaniques spécifiées.

Finition de surface pour améliorer les performances : selon les exigences de l’application, différents procédés de finition peuvent être appliqués. L’électropolissage pour pièces de précision réduit efficacement la rugosité de surface, améliore la résistance à la corrosion et diminue les pertes de charge en écoulement. Pour les composants nécessitant une esthétique haut de gamme ou des surfaces ultra lisses, le service de polissage de pièces CNC permet d’obtenir une finition miroir.

Inconel DMLS vs usinage CNC traditionnel : comment choisir ?

Le choix entre DMLS et usinage CNC traditionnel nécessite une évaluation globale. Le DMLS excelle pour la complexité géométrique, l’utilisation de la matière et le prototypage rapide, tandis que l’usinage conventionnel par services d’usinage de précision présente des avantages clairs pour les géométries plus simples, la production en grande série, les tolérances dimensionnelles très serrées et des états de surface supérieurs, le tout de manière économiquement compétitive.

Notre recommandation : lorsque votre pièce implique des canaux internes complexes, des structures intégrées ou une production en faible volume / prototypes, le DMLS est la solution idéale. Pour des géométries plus simples destinées à la production de masse, l’ usinage multi-axes traditionnel est souvent plus économique et plus efficace. À noter : le service intégré « one-stop » de Neway permet de combiner de manière flexible les atouts du DMLS et de l’usinage CNC dans une fabrication hybride — par exemple, en utilisant le DMLS pour produire une ébauche proche du net shape avec des caractéristiques complexes, puis en appliquant un usinage CNC 5 axes sur les interfaces critiques afin d’obtenir des performances globales optimales.

Cas d’application industriels de la technologie DMLS Inconel

Aéronautique et aviation : le DMLS est idéal pour la fabrication d’injecteurs de carburant, d’aubes de turbine, de chambres de combustion de fusées et de composants similaires. Sa capacité à intégrer directement des canaux de refroidissement internes complexes se traduit par une amélioration de l’efficacité des moteurs et un meilleur rapport poussée/poids.

Production d’énergie : dans les turbines à gaz et le nucléaire, le DMLS permet de produire des disques de turbine, des aubes et des composants de vannes résistants aux hautes températures et dotés d’une résistance à la corrosion exceptionnelle, par exemple des pièces en Hastelloy C-276.

Dispositifs médicaux : dans le domaine médical, le DMLS permet de créer des guides chirurgicaux sur mesure, des dispositifs de fixation et des implants orthopédiques biocompatibles (sous réserve de certifications), contribuant ainsi au développement de la médecine de précision.

Capacités de Neway pour les services DMLS Inconel

Chez Neway, nous nous engageons à fournir des solutions DMLS Inconel de classe mondiale. Nous exploitons des systèmes DMLS avancés et maintenons des bases de données de paramètres de procédé rigoureusement validées pour de nombreux matériaux, notamment l’Inconel 738. Notre équipe d’ingénieurs possède une expertise approfondie du comportement des alliages Inconel et peut offrir un support de bout en bout — depuis l’optimisation de la conception et l’élaboration de la stratégie de construction jusqu’au post-traitement complet, y compris la finition haute précision par service d’usinage par électro-érosion (EDM). Que vous ayez besoin d’un service de prototypage en amont pour valider votre conception ou que vous soyez prêt à passer à une production en petites séries, Neway est un partenaire de confiance.

Conclusion : adopter l’avenir de la fabrication

La combinaison de l’Inconel et du DMLS repousse continuellement les limites de la conception et de la fabrication de pièces haute performance, soutenant l’innovation dans l’aéronautique, l’énergie, le médical et d’autres secteurs critiques. Choisir Neway, c’est bénéficier d’un partenaire de fabrication qui allie expertise technique pointue et vaste expérience projet. Nous vous invitons sincèrement à nous contacter pour explorer comment l’impression 3D avancée en Inconel peut transformer vos conceptions de pointe en réalités fiables et efficaces.