Certificado ISO 9001

Garantía de Calidad para Piezas CNC Personalizadas

Las pruebas y garantía de calidad de piezas personalizadas aseguran que los componentes mecanizados CNC cumplan con los más altos estándares de rendimiento, durabilidad y precisión. Mediante rigurosas pruebas e inspecciones, validamos la funcionalidad, las propiedades del material y la precisión dimensional, garantizando fiabilidad para diversas aplicaciones.

Máquina de Medición por Coordenadas (CMM)

La Máquina de Medición por Coordenadas (CMM) realiza inspecciones dimensionales de alta precisión en piezas mecanizadas CNC. Utilizando sondas táctiles u ópticas, la CMM captura geometrías exactas y verifica la conformidad con las tolerancias. Asegura que los componentes CNC cumplan estrictos requisitos dimensionales, de forma y posición, apoyando la inspección del primer artículo, validación de procesos y garantía de calidad en aplicaciones aeroespaciales, automotrices e industriales.

Instrumento de Medición de Contorno

El Instrumento de Medición de Contorno realiza análisis ultra-precisos del perfil superficial y contorno de piezas CNC. Evalúa precisión de forma, ondulación y alturas de escalones con resolución micrométrica. Garantiza que superficies críticas y perfiles funcionales cumplan con especificaciones estrictas, apoyando la garantía de calidad en industrias aeroespacial, automotriz y de mecanizado industrial de alta precisión.

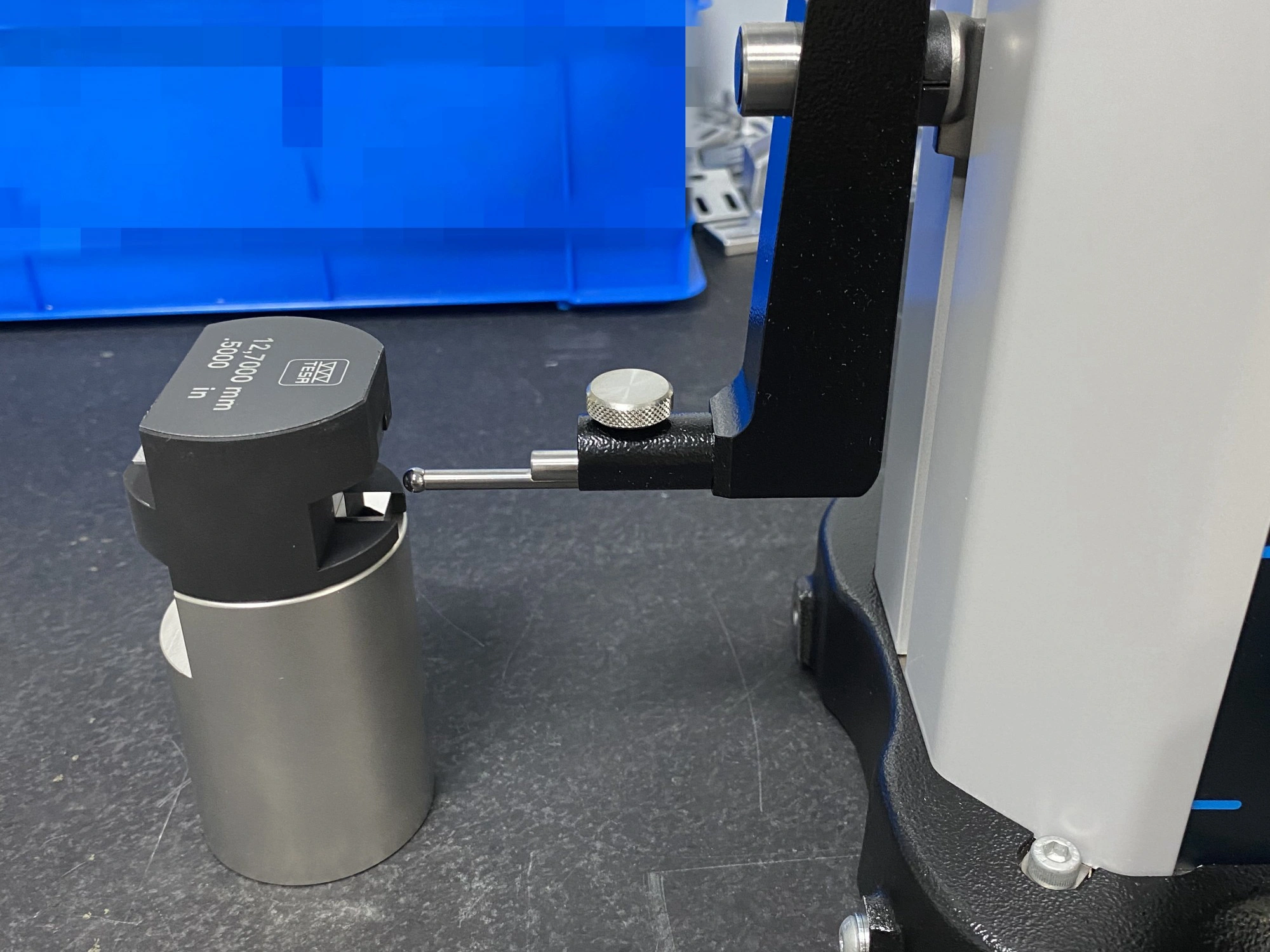

Calibrador de Altura

El calibrador de altura ofrece mediciones verticales de alta precisión para piezas CNC. Verifica alturas, profundidades de escalones y distancias verticales con exactitud micrométrica. Es esencial para inspección de primer artículo, control de procesos y garantía de calidad en mecanizado aeroespacial, automotriz e industrial de componentes críticos.

Equipo de Pruebas Ultrasónicas

El equipo de pruebas ultrasónicas permite la evaluación no destructiva de defectos internos en piezas CNC. Utilizando ondas sonoras de alta frecuencia, detecta fallas subsuperficiales como grietas, inclusiones y delaminación. Es esencial para la garantía de calidad y verificación de integridad estructural en aplicaciones aeroespaciales, automotrices e industriales críticas.

Taller de Inspección por Rayos X

El taller de inspección por rayos X realiza análisis no destructivos de defectos internos en piezas CNC. Utilizando rayos X de alta energía, visualiza estructuras internas para detectar porosidad, grietas, inclusiones e inconsistencias dimensionales. Es crítico para la garantía de calidad, validación estructural y control de procesos en aplicaciones aeroespaciales, automotrices e industriales de precisión.

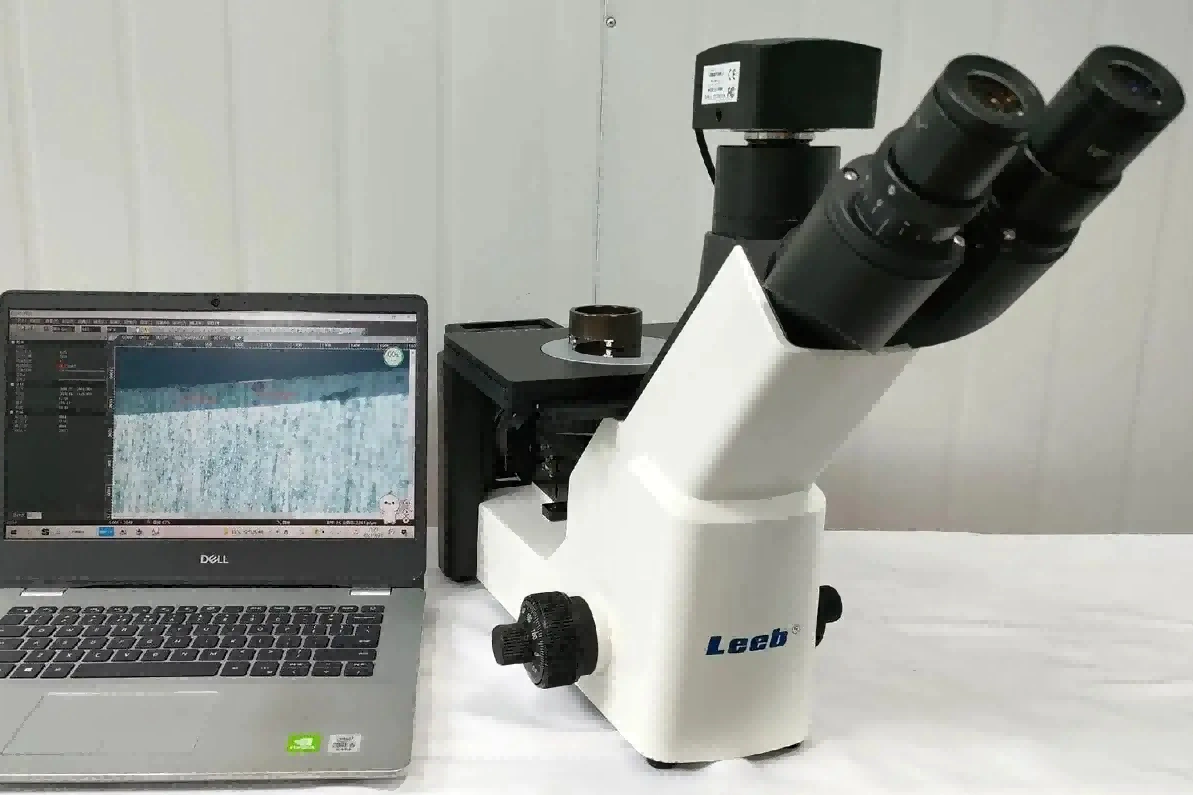

Microscopía Metalográfica

La microscopía metalográfica ofrece análisis de microestructura de alta resolución en piezas CNC. Revela la estructura del grano, distribución de fases y defectos superficiales mediante secciones transversales pulidas. Es esencial para validar procesos de mecanizado, resultados de tratamientos térmicos y correlaciones de propiedades mecánicas en componentes aeroespaciales, automotrices e industriales de alta precisión.

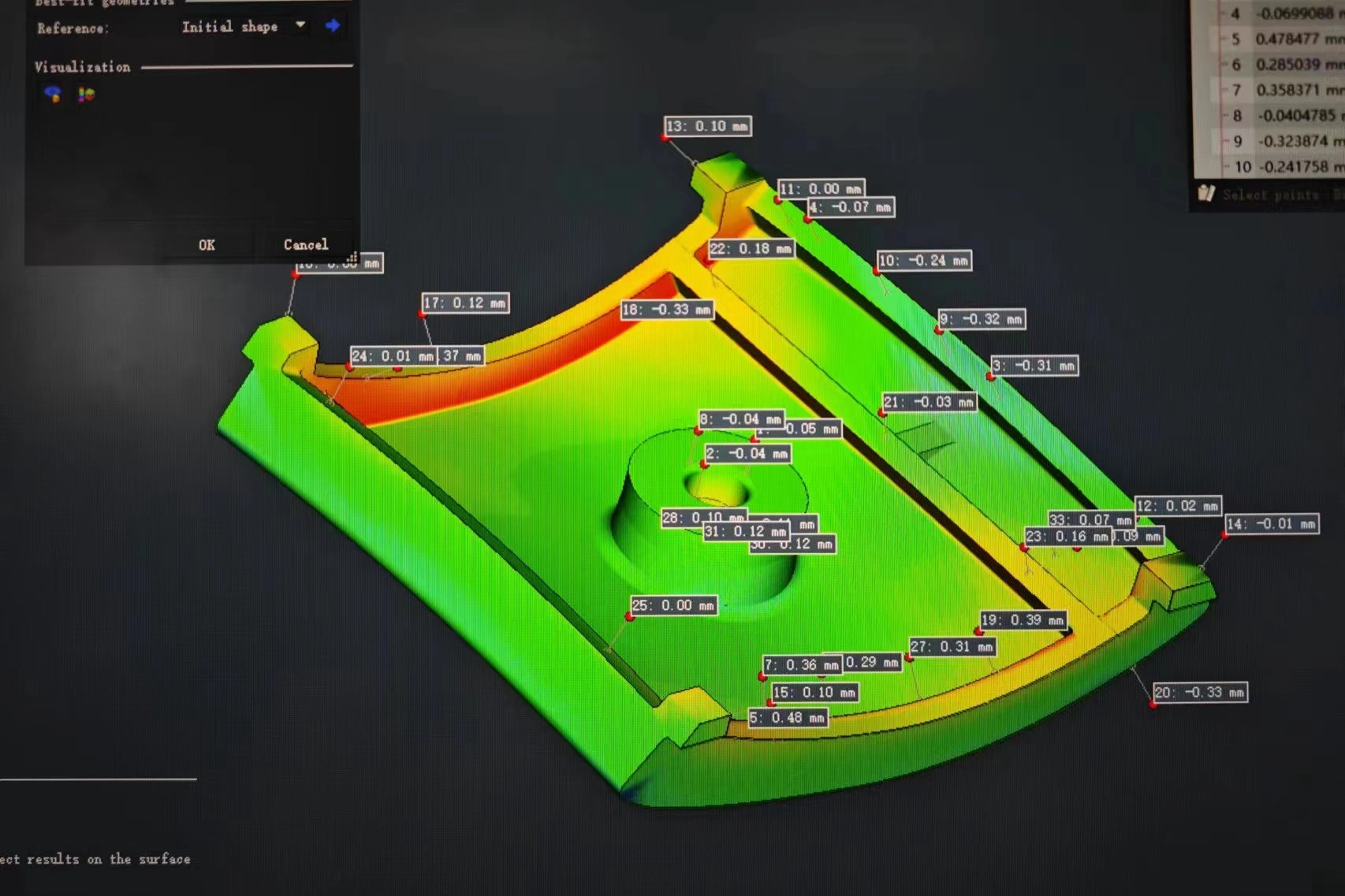

Instrumento de Medición por Escaneo 3D

El instrumento de medición por escaneo 3D realiza inspecciones dimensionales de alta precisión y sin contacto de piezas CNC. Captura la geometría superficial completa con precisión micrométrica. Es esencial para validar geometrías complejas, detectar desviaciones dimensionales y asegurar la conformidad con modelos CAD en aplicaciones aeroespaciales, automotrices e industriales de precisión.

Comencemos un nuevo proyecto hoy