Stainless Steel CNC Machining: 8 Common Considerations

Introduction: Challenges and Value of Stainless Steel CNC Machining

As a senior mechanical engineer at Neway, my extensive experience in stainless steel CNC machining services has provided me with a deep understanding that this material not only offers excellent performance but also presents unique machining challenges. Thanks to its outstanding corrosion resistance and strength-to-appearance ratio, stainless steel is highly favored in various fields, including medical devices, the food industry, and aerospace. However, its tendency toward work hardening, high toughness, and relatively low thermal conductivity necessitates the adoption of more scientific and systematic machining strategies.

In our daily work, we often see that part quality fails to meet requirements because a critical factor has been overlooked. Therefore, I have summarized the eight most important considerations to help you make the right decisions at the early stage of your project, avoid common pitfalls, and secure high-quality stainless steel machined components.

Consideration 1: Selecting the Most Suitable Stainless Steel Grade

Selecting the right stainless steel grade is the foundation of success. Different grades vary significantly in chemical composition, crystal structure, and mechanical properties, which directly affect machinability and the performance of the final parts.

For example, SUS303 stainless steel, with added sulfur, offers excellent machinability and is particularly suitable for components requiring extensive machining. However, its corrosion resistance is relatively inferior, making it unsuitable for harsh corrosive environments. In contrast, SUS316 stainless steel, which contains molybdenum, has significantly improved pitting resistance in chloride environments, making it ideal for marine and chemical applications, though it is more difficult to machine.

For applications requiring high strength and hardness, such as cutting tools or bearings, we recommend SUS420 or SUS440C. For scenarios that require both high strength and excellent corrosion resistance, such as aerospace components, SUS630 (17-4PH) can achieve tensile strengths exceeding 1000 MPa through precipitation hardening.

Consideration 2: Specialized Tooling and Geometry Selection

Stainless steel machining requires dedicated cutting tool solutions. Standard HSS or conventional carbide tools rarely deliver ideal performance in stainless steel applications, so we typically recommend fine-grain carbide tools combined with specialized coatings.

Tool geometry must be carefully engineered. We generally use a larger rake angle (10°–15°) to reduce cutting forces and mitigate work hardening, along with positive rake and inclination angles to improve chip evacuation. Sharp cutting edges are essential; even minor edge damage can intensify work hardening and degrade surface quality. For tougher materials like SUS316L stainless steel, we also select larger nose radii to dissipate cutting heat and extend tool life.

In real-world production, we select dedicated tools for different operations. For roughing, we use robust tool bodies with large chip flutes; for finishing, we choose multi-flute tools with specially prepared cutting edges to ensure excellent surface finish. This refined tooling strategy is a key strength of our precision machining services.

Consideration 3: Optimizing Cutting Parameters and Thermal Management

Optimizing cutting parameters is critical to successful stainless steel machining. Due to its low thermal conductivity, heat generated during cutting is difficult to dissipate, leading easily to tool overheating and premature failure. We precisely control cutting speed, feed rate, and depth of cut to manage cutting temperature.

In CNC milling services, we employ moderate cutting speeds and appropriate feed rates to ensure that heat is effectively dissipated through the chips. Excessively low cutting speeds tend to increase abrasive wear, while overly high speeds can cause plastic deformation. For CNC turning services, we pay particular attention to maintaining stable cutting loads to avoid vibration and work hardening caused by parameter fluctuations.

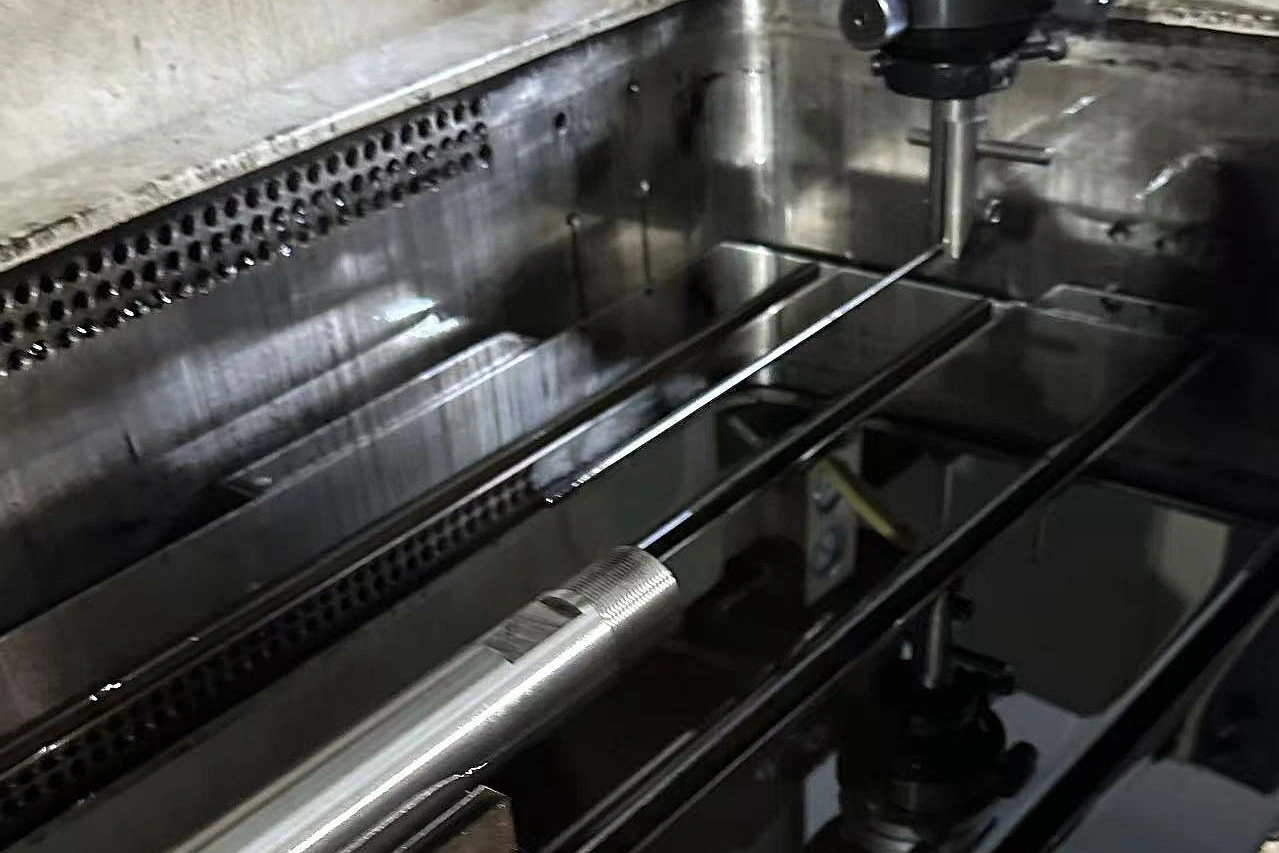

Coolant selection and application are equally important. We use high-lubricity, stainless-steel-specific cutting fluids and deliver them directly to the tool–chip interface through high-pressure systems. This effectively reduces cutting temperature and improves chip breaking. For deep-hole or cavity machining, we utilize through-coolant tools to ensure that coolant reaches the most critical, heat-concentrated areas.

Consideration 4: Workholding and Rigidity Assurance

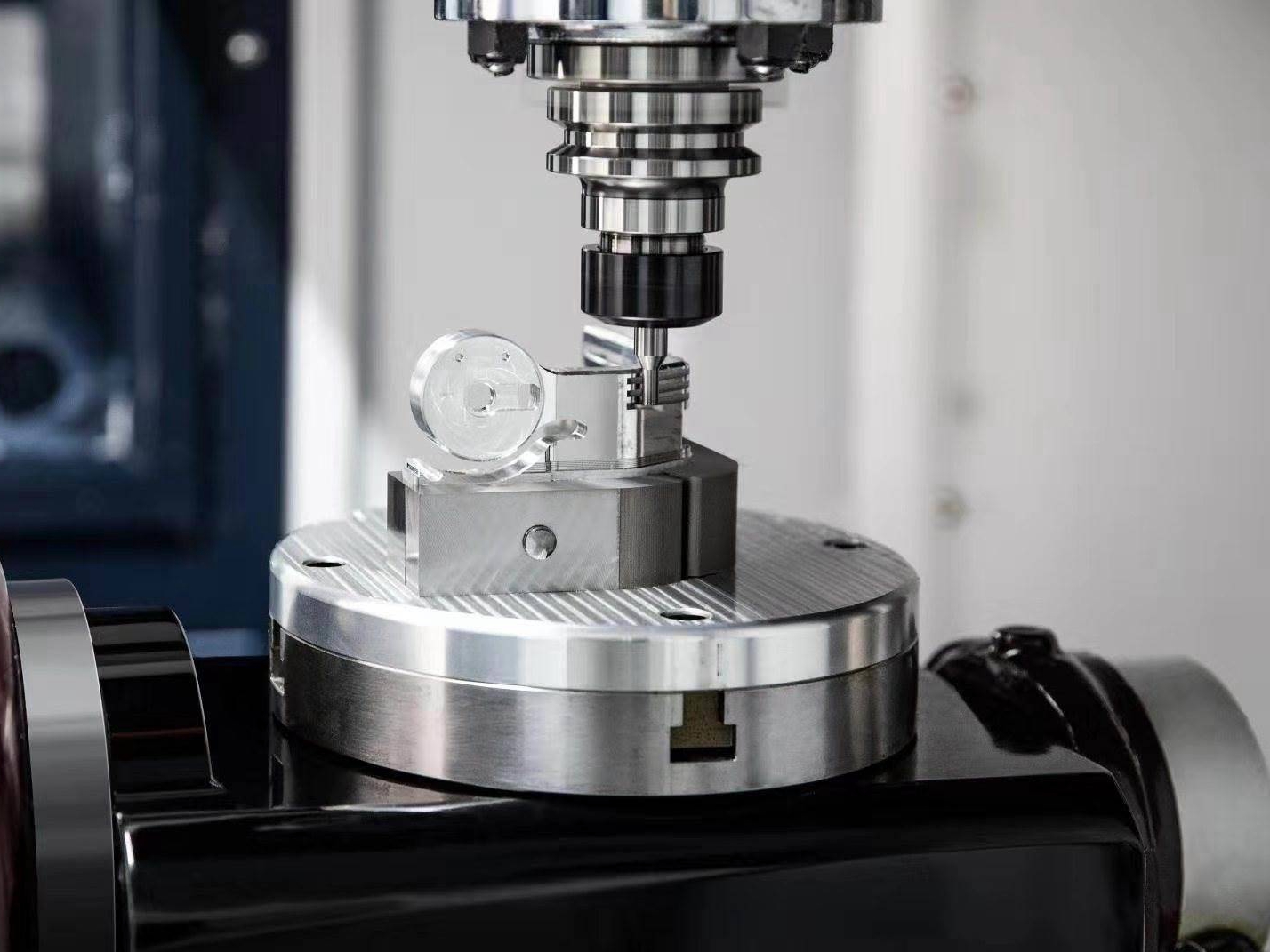

Stainless steel machining places extremely high demands on system rigidity. Even slight vibration can cause surface finish deterioration, dimensional deviations, and reduced tool life. Based on the part geometry and machining requirements, we design dedicated fixturing solutions to ensure stable clamping throughout the process.

For thin-walled or complexly shaped parts, we employ segmented machining strategies, multiple clamping stages, or flexible fixtures to minimize deformation. In our multi-axis machining services, we leverage the advantages of 5-axis machines to reduce repeated repositioning and ensure the tool remains in an optimal cutting orientation.

Consideration 5: Addressing Work Hardening

Work hardening is one of the most challenging characteristics of stainless steel. During cutting, the plastic deformation of the lattice structure significantly increases the hardness in the affected layer, creating major difficulties for subsequent operations. We apply a variety of process measures to manage this issue.

First, we ensure tools remain sharp at all times to prevent additional hardening caused by worn edges. Second, we use sufficient depth of cut so that the cutting edge engages beneath the hardened layer, avoiding “rubbing” instead of cutting within the hardened zone. In CNC drilling services, we pay special attention to hole quality, using step drilling strategies and specialized drill geometries to effectively prevent work hardening on hole walls.

Consideration 6: Chip Control and Evacuation Management

Stainless steel machining often generates long, tough chips that, if not properly controlled, may wrap around tools or parts, causing interruptions or even equipment damage. We optimize chipbreaker design and adjust cutting parameters to achieve effective chip control.

During roughing, we aim to produce short “C-shaped” chips that are easier for automatic chip conveyors to handle. During finishing, we focus on directing chip flow away from finished surfaces to prevent scratching. For deep cavity machining, we also utilize compressed air to assist in chip evacuation and maintain a clean cutting area.

Consideration 7: Part Geometry and Process Planning

Part geometry directly affects process strategy. During process planning, we comprehensively analyze the structural features, identify potential machining challenges such as deep cavities, thin walls, and sharp corners, and develop targeted solutions.

For components with complex geometries, we often combine multiple machining technologies. For example, we may use EDM services to create complex cavities in the base material, followed by CNC grinding services to achieve final dimensional accuracy and surface quality. This hybrid process route maximizes the strengths of different methods, delivering high-quality parts in a cost-effective way.

Consideration 8: Post-Processing and Surface Finishing Options

Surface treatment for stainless steel parts not only affects aesthetics but also plays a critical role in functional performance. We recommend the most suitable surface treatment based on the application environment. Electropolishing provides a clean, smooth surface, making it ideal for medical and food-industry components with strict hygiene requirements. Passivation removes free iron from the surface and forms a chromium-rich oxide layer, significantly enhancing corrosion resistance.

For parts that require unique visual effects or enhanced surface properties, we offer CNC polishing and PVD coating services. PVD coatings not only provide multiple color options but also significantly improve surface hardness, wear resistance, and corrosion resistance, making them particularly suitable for high-end consumer electronics and luxury products.

Neway’s Professional Stainless Steel CNC Machining Solutions

At Neway, we systematically integrate the above eight key considerations into our machining system. From process validation during the prototyping services stage to process stabilization during mass production services, we consistently uphold a rigorous and scientific approach. Our engineering team is highly familiar with the characteristics of various stainless steel materials and can provide optimized machining solutions tailored to your specific requirements.

We understand that successful stainless steel machining is not just about optimizing individual steps, but about the synergy of the entire process chain. Through our comprehensive one-stop service, you gain full support from material selection and process design to post-processing, ensuring that your stainless steel components achieve the optimal balance of performance, cost, and lead time.

FAQ

What are the main differences between machining SUS304 and SUS316 stainless steel?

Why is tool life shorter when machining stainless steel, and how can it be improved?

How do I select the most suitable surface treatment for stainless steel parts?

How should burrs and sharp edges be handled after machining stainless steel using CNC?

My product prototype requires machining with stainless steel. Can Neway provide support?