Как Neway обеспечивает точность формы дна и размеров при глухом глубоком сверлении?

В компании Neway достижение точной формы дна и строгой размерной точности в глухих глубоких отверстиях является одной из самых сложных задач высокоточной механической обработки. Для этого требуются специализированный инструмент, продвинутый контроль процесса и серьёзная инженерная экспертиза. Мы разработали комплексные решения, которые позволяют уверенно решать эти задачи для разных материалов и областей применения.

Специализированный инструмент для контроля формы дна отверстия

Конфигурация дна отверстия в первую очередь определяется выбором инструмента и стратегией обработки. Мы используем несколько специализированных подходов к инструменту, чтобы получить требуемую геометрию дна.

Системы сверления с плоским дном

Для получения действительно плоского дна мы применяем специальные сверла с плоским дном и особой заточкой режущих кромок, формирующих ровную, перпендикулярную поверхность. Такие инструменты особенно эффективны в материалах, таких как алюминий 6061 и нержавеющая сталь SUS303, где мы можем обеспечивать плоскостность дна в пределах 0,01 мм по всей поверхности. Геометрия инструмента включает тщательно рассчитанные задние углы и подготовку режущей кромки для чистого отделения материала в центральной зоне.

Инструмент для профилированного (контурного) дна

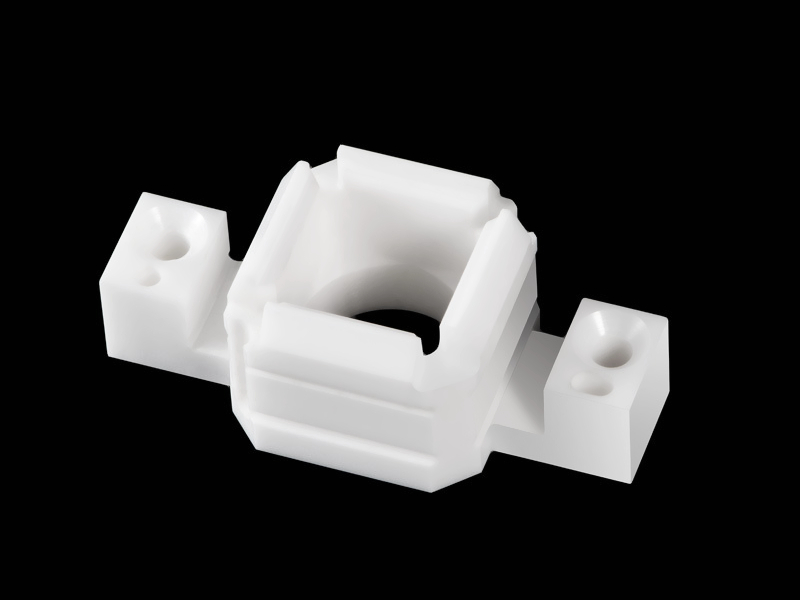

Для задач, где требуется специальная форма дна (например, сферическая, коническая или произвольный профиль), мы используем фасонный инструмент с режущей частью, точно повторяющей требуемую геометрию. Такой подход широко применяется в системах впрыска топлива для автоиндустрии и в компонентах для медицинских устройств, где гидродинамика потока напрямую зависит от внутреннего контура отверстия.

Интеграция нетрадиционных методов обработки

В ряде сложных случаев, особенно при обработке закалённых материалов или очень сложной геометрии, мы комбинируем традиционное сверление с электроэрозионной обработкой (EDM), чтобы получить точные элементы дна, которые невозможно выполнить только режущим инструментом.

Продвинутый контроль процесса для обеспечения размерной точности

Поддержание точности размеров по всей глубине глухого отверстия требует одновременного решения нескольких технических задач.

Управление эвакуацией стружки

В глухих отверстиях по мере увеличения глубины удаление стружки становится критичным. Мы применяем несколько стратегий:

Циклы прерывистого сверления (peck drilling) с оптимизированной длиной отхода для дробления и вывода стружки;

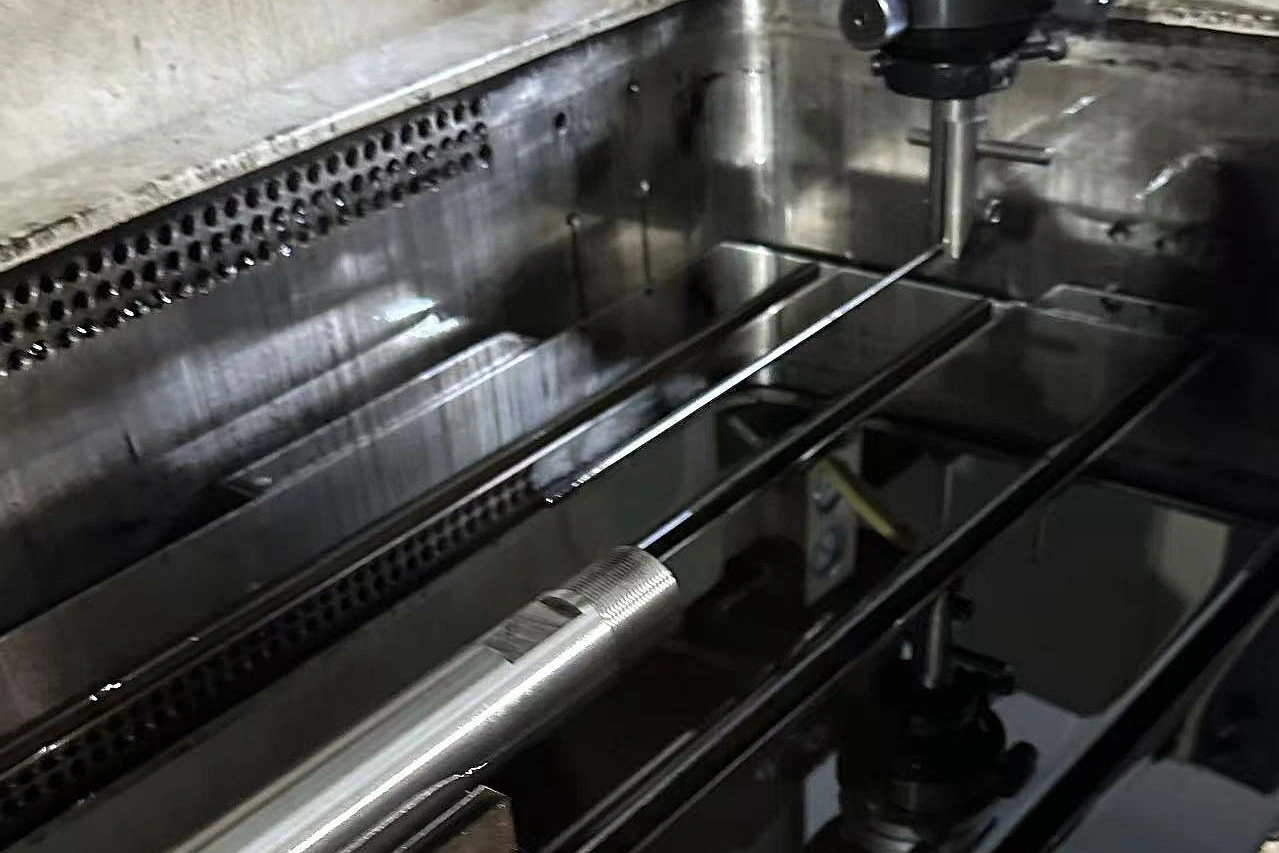

Системы охлаждения высокого давления с подачей СОЖ по внутренним каналам инструмента для выталкивания стружки из отверстия;

Индивидуально подобранные режимы резания, формирующие короткую, управляемую стружку вместо длинной непрерывной.

Компенсация тепловых деформаций

Продолжительное резание и ограниченное пространство в глубоких отверстиях приводят к интенсивному тепловыделению. Наш подход включает:

Тепловое моделирование для прогнозирования теплового расширения детали и инструмента в процессе обработки;

Системы контроля температуры СОЖ, поддерживающие стабильные тепловые условия;

Встроенную компенсацию на основе данных мониторинга критических размеров в реальном времени.

Контроль прогиба инструмента

С увеличением длины сверла прогиб инструмента становится одним из ключевых факторов, влияющих на точность. Мы решаем эту задачу с помощью:

Оптимизированных по жёсткости держателей инструмента с минимальным вылетом;

Пошаговых (прогрессивных) схем сверления, начинающихся с более коротких и жёстких инструментов;

Систем активного мониторинга инструмента, которые обнаруживают прогиб и позволяют оперативно корректировать режимы.

Методы высокоточной измерительной и контрольной проверки

Проверка размеров и геометрии дна глухих отверстий требует специализированных методов измерения, выходящих за рамки стандартных средств контроля.

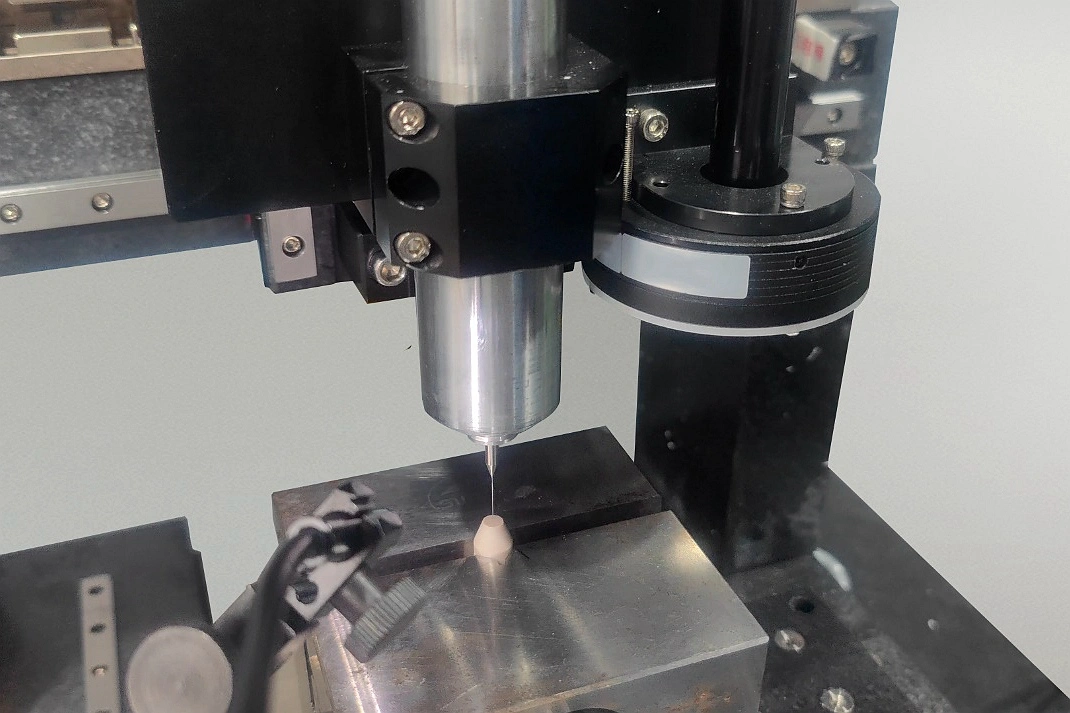

Бесконтактный внутренний контроль

Мы используем высокоточные борскопы и видеозонды с артикулируемыми головками для визуального контроля дна и стенок отверстия. Эти системы обеспечивают увеличенное изображение внутренней поверхности, что позволяет оценить качество шероховатости и выявить дефекты в зоне глухого дна.

Разработка специальных калибров

Для критических размеров мы проектируем и изготавливаем специальные калибр-пробки с рабочими поверхностями, соответствующими требуемой форме дна. Такие калибры позволяют одновременно контролировать глубину и форму дна по принципу проход/непроход.

КИМ с длинными специализированными щупами

Наши координатно-измерительные машины оснащены длинными, тонкими щупами со «звёздочными» наконечниками, которые могут глубоко проникать в глухие отверстия и формировать набор измерительных точек на дне. Этот подход особенно востребован для компонентов высокоточной механической обработки в авиационно-космической отрасли, где требуется полная размерная сертификация.

Стратегии обработки с учётом типа материала

Разные материалы предъявляют свои требования к обработке глухих глубоких отверстий, поэтому для каждого семейства сплавов мы используем адаптированные технологии.

Алюминий и цветные сплавы

Для материалов, таких как алюминий 7075 и медные сплавы, мы фокусируемся на:

Предотвращении наростообразования за счёт специальных покрытий инструмента;

Оптимизации качества поверхности благодаря полированным канавкам инструмента;

Исключении приваривания стружки путём точной настройки режимов резания.

Жаропрочные сплавы

Для сложных материалов, таких как Inconel 718 и Ti-6Al-4V (TC4), наш подход включает:

Консервативные режимы резания для контроля наклёпа и нагрева зоны резания;

Специальную геометрию инструмента с высокими положительными передними углами;

Использование передовых инструментальных материалов, включая твёрдосплавные и PCD-наконечники.

Закалённые стали

Для предварительно закалённых сталей, таких как 4140 и инструментальные стали, мы применяем:

Твёрдосплавный инструмент с износостойкими покрытиями;

Снижение сил резания за счёт траекторий типа трокоида при рассверливании/фрезеровании полостей;

Демпфирующие держатели инструмента для минимизации вибраций и биения в глубоких полостях.

Интегрированная система обеспечения качества

Наш подход к обеспечению качества глухих глубоких отверстий охватывает весь производственный цикл.

Предварительная валидация процесса

До начала обработки мы выполняем:

Проверку биения инструмента для обеспечения соосности и стабильности резания;

Тестирование давления СОЖ для подтверждения достаточного расхода и корректной подачи в зону обработки;

Имитацию (симуляцию) программы для визуализации всей последовательности операций.

Мониторинг в ходе обработки

В процессе обработки мы используем:

Контроль крутящего момента для раннего выявления износа инструмента до ухудшения качества деталей;

Акустические датчики для распознавания забивания стружкой и других аномалий;

Адаптивные системы управления, корректирующие подачу в зависимости от фактических условий резания.

Проверка после обработки

После завершения обработки мы проводим:

Разрушающий контроль первых деталей для валидации внутренней геометрии и формы дна;

Статистический контроль процесса по ключевым размерам;

Измерение шероховатости дна отверстия с помощью реплик или специальных методик.

Такой комплексный подход гарантирует, что глухие глубокие отверстия соответствуют самым строгим требованиям по форме дна и размерной точности, поддерживая критические применения в отраслях автомобилестроения, энергетики и промышленного оборудования.