ЧПУ-обработка нержавеющей стали: всё, что нужно знать

Введение: нержавеющая сталь — выдающиеся свойства и сложная обрабатываемость

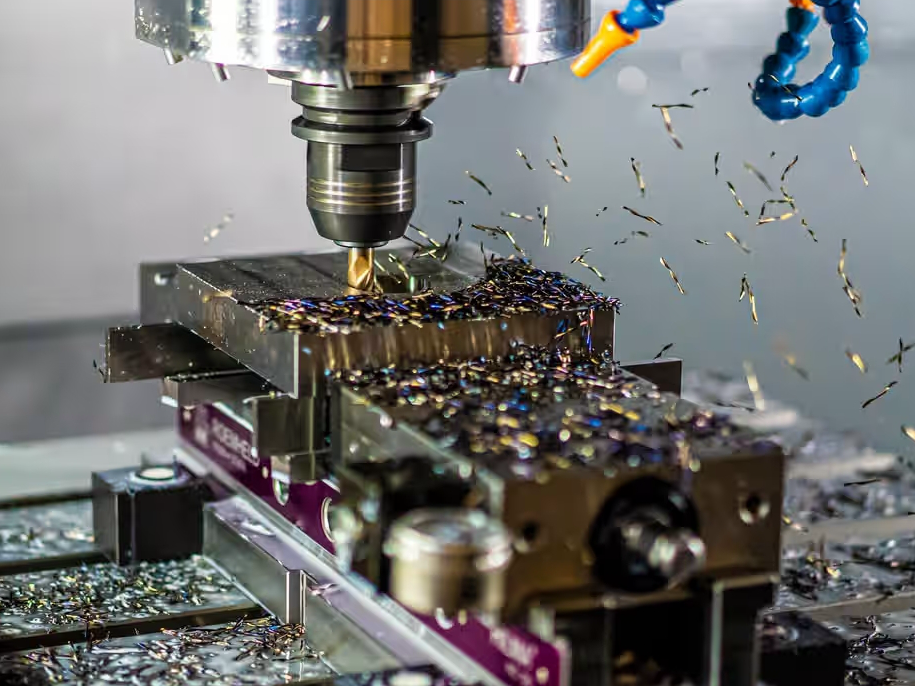

В современной прецизионной механической обработке нержавеющая сталь выделяется сочетанием исключительной коррозионной стойкости, высокой механической прочности и чистого, эстетичного внешнего вида. Как ведущий инженер-технолог в компании Neway, я каждый день вижу, что за этими преимуществами стоят весьма серьёзные вызовы в обработке. По сравнению с многими другими металлами нержавеющая сталь создаёт повышенные силы резания, интенсивно наклёпывается и ускоряет износ инструмента — всё это требует специальных стратегий, оптимизированного инструмента и стабильного контроля процесса.

В наших повседневных услугах по обработке нержавеющей стали на ЧПУ мы также замечаем, что многие инженеры концентрируются только на эксплуатационных характеристиках (прочность, коррозионная стойкость, внешний вид) и недооценивают сложность правильной обработки этих марок. На практике лишь глубокое понимание металлургии нержавеющих сталей и их поведения при резании позволяет в полной мере раскрыть их потенциал и стабильно получать строгие допуски, чистые поверхности и долговечные детали. Опираясь на наш накопленный опыт, это руководство систематически разбирает ключевые технические аспекты обработки нержавеющей стали на ЧПУ.

Семейства нержавеющих сталей: три ключевых типа и как их выбирать

Аустенитные нержавеющие стали: немагнитные, коррозионностойкие — и трудные в обработке

Аустенитные марки — самые широко используемые; они известны отличной коррозионной стойкостью и немагнитным поведением. Для них характерно повышенное содержание хрома (≈18 % и выше) и никеля (≈8 % и выше). Типичные марки — SUS303, SUS304 и SUS316. SUS303 содержит серу/селен для улучшения обрабатываемости и идеально подходит для массового точения и автоматных работ. SUS304 — «рабочая лошадка» общего назначения с хорошим балансом стоимости, коррозионной стойкости и прочности. SUS316, легированная молибденом, обеспечивает повышенную стойкость к питтинговой коррозии, особенно в средах с хлоридами и морской воде.

Мартенситные нержавеющие стали: высокая твёрдость, термообрабатываемость, износостойкость

Мартенситные стали разрабатываются для получения высокой твёрдости и прочности за счёт термообработки. Типичные примеры — SUS420 и SUS440C с повышенным содержанием углерода (примерно 0,15–1,0 %). После закалки и отпуска они достигают очень высоких значений твёрдости и широко применяются для лезвий, подшипниковых элементов, клапанов, точного инструмента и ряда медицинских изделий, где требуются износостойкость и базовая коррозионная стойкость.

Прецизионно упрочняемые (PH) нержавеющие стали: сверхвысокая прочность при контролируемой термообработке

Прецизионно упрочняемые нержавеющие стали (PH) достигают высокой прочности за счёт старения, во время которого выделяются мелкодисперсные упрочняющие фазы. Ключевой представитель — SUS630 (17-4PH). В состоянии после растворного отжига она обрабатывается относительно легко; после старения при 480–620 °C её временное сопротивление разрыву может превышать 1000 МПа при сохранении хорошей вязкости. Эти стали широко применяются в аэрокосмической технике, высокоточных приборах и ответственных медицинских и промышленных компонентах, где необходимы высокая прочность, стабильность и коррозионная стойкость.

Четыре ключевые проблемы при обработке нержавеющей стали на ЧПУ и как мы их решаем

1. Наклёп: механизм, риски и способы контроля

Нержавеющие стали, особенно аустенитные, сильно склонны к наклёпу. Интенсивная пластическая деформация в зоне резания повышает плотность дислокаций и локальную твёрдость, что усложняет последующие проходы и увеличивает силы резания. Чтобы минимизировать этот эффект, мы:

Применяем достаточную глубину резания, чтобы каждый проход резал ниже упрочнённого слоя, а не «терся» по нему.

Используем очень острые режущие кромки для минимизации деформации и трения.

Избегаем выдержек врезания, «натирания» и многократных лёгких проходов по одному и тому же тракту.

Подбираем скорости резания, позволяющие контролировать температуру и снижать эффект наклёпа.

2. Высокие силы резания: геометрия инструмента и оптимизация режимов

Высокая прочность и вязкость нержавеющих сталей приводят к увеличению сопротивления резанию, что может вызывать вибрации, виброрябь, «уплывание» размеров и сложности с жёсткой фиксацией. В наших операциях фрезерования на ЧПУ мы:

Используем положительные передние углы (≈15–20°) для снижения сил резания.

Применяем задние углы порядка 8–10°, чтобы сохранить поддержку и уменьшить износ по задней поверхности.

Оптимизируем стружколомы и стратегии ступенчатого съёма, поддерживая стабильную толщину стружки.

Находим баланс между производительностью и стабильностью, а не просто «выкручиваем» подачи и скорости.

3. Износ инструмента: налипание, наросты на кромке и диффузионный износ

При резании нержавеющих сталей часто наблюдаются кратерный износ по передней поверхности и равномерный износ по задней из-за высоких температур резания, диффузии легирующих элементов и адгезии. Наши меры:

Используем мелкозернистые твёрдосплавные пластины с высокой горячей твёрдостью и вязкостью.

Применяем PVD-покрытия, такие как TiAlN, AlTiN или AlCrN, обладающие высокой термостойкостью и антиадгезионными свойствами.

Разделяем инструмент по назначению: более вязкие марки для черновой обработки и более острые, твёрдые покрытия — для чистовой.

Вводим жёсткую систему управления стойкостью, чтобы менять пластины до возникновения разрушения.

4. Управление теплом: стратегия охлаждения и контроль термических деформаций

Относительно низкая теплопроводность нержавеющих сталей концентрирует тепло в зоне резания и у режущей кромки, ускоряя износ и вызывая деформации деталей. Мы:

Используем высоконапорную подачу СОЖ (часто 70–100 бар), чтобы пробить паровой барьер и эффективно вымывать стружку.

Подбираем специализированные для нержавейки охлаждающие жидкости с EP-присадками для совмещения смазки и охлаждения.

Применяем инструмент с внутренними каналами охлаждения при сверлении, нарезании резьбы и обработке глубоких отверстий.

Контролируем температуру окружающей среды и станка при обработке высокоточных деталей.

Комплексная процессная стратегия для обработки нержавеющей стали на ЧПУ

Стратегия выбора инструмента: основа, геометрия и покрытие

В основном мы используем мелкозернистые твёрдосплавные инструменты со следующими характеристиками:

Положительный передний угол для снижения сил резания и тепловыделения.

Укреплённая режущая кромка для предотвращения микросколов при ударных нагрузках.

Острая, аккуратно притуплённая кромка (honing), уменьшающая наклёп и образование наростов.

Для чистовой обработки инструменты с покрытиями TiAlN/AlCrN обеспечивают отличную жаростойкость и пониженное трение, что даёт стабильную стойкость и высокое качество поверхности на аустенитных и PH-марках.

Режимы резания: согласование скорости, подачи и глубины для каждой марки

Мы всегда калибруем режимы с учётом марки стали, жёсткости системы и конкретной операции. Для фрезерования SUS304 типовое стартовое «окно» может быть таким:

Скорость резания: 80–120 м/мин

Подача на зуб: 0,08–0,15 мм/зуб

Осевое заглубление (DOC): 0,5–3 мм

Радиальное перекрытие: 30–50 % диаметра инструмента

Для высокоточных элементов мы немного уменьшаем глубину резания и подачу, делая акцент на стабильности и применяя несколько последовательных чистовых проходов.

Стратегия применения СОЖ: тип, концентрация и подача

Мы рекомендуем высококачественные эмульсионные или полусинтетические СОЖ, как правило с концентрацией 8–12 %. Высоконапорная подача с направленными соплами или внутриподоводом позволяет:

Снижать температуру в зоне сдвига.

Предотвращать повторный рез стружки и образование наростов на кромке.

Улучшать чистоту поверхности и повышать стойкость инструмента.

Установка и базирование: жёсткость без деформаций

Детали из нержавеющей стали, особенно тонкостенные, чувствительны к силам зажима и резания. Мы:

Используем мягкие губки, специальные кулачки по контуру или вакуумные приспособления для равномерного распределения давления зажима.

Добавляем опорные элементы и подпорки в зонах тонких стенок.

Строим маршрут обработки по схеме: черновая → снятие напряжений (при необходимости) → получистовая → чистовая.

Применяем многоосевую обработку, чтобы выполнить больше операций за одну установку и уменьшить погрешности переустановки.

Особенности обработки ключевых марок нержавеющей стали

SUS303: оптимизирована под высокую обрабатываемость

Благодаря добавкам S/Se SUS303 образует стружку легче и снижает силы резания. Типовые режимы фрезерования: скорость резания 100–150 м/мин, подача 0,15–0,25 мм/зуб. Прекрасно подходит для валов, крепежа, фитингов и токарных деталей. Важно помнить: коррозионная стойкость ниже, чем у SUS304, поэтому эту марку нежелательно использовать в особо агрессивных средах.

SUS304: универсальный стандарт

SUS304 требует тщательно сбалансированных режимов: 80–120 м/мин и толщина стружки 0,10–0,20 мм/зуб — хороший исходный диапазон. Важно контролировать тепловложение, чтобы избежать сенсибилизации и сохранить коррозионную стойкость. Для ответственных применений мы часто дополняем мехобработку пассивацией, восстанавливая и усиливая пассивную плёнку.

SUS316: легирование молибденом и повышенные требования к обработке

SUS316 / 316L обеспечивает улучшенную стойкость к хлоридам, но обрабатывается сложнее и быстрее наклёпывается. Мы рекомендуем несколько более низкие скорости резания (70–110 м/мин) и подачу 0,08–0,15 мм/зуб, с непрерывным резанием без выдержек. Эти марки широко применяются в химической промышленности, морской среде, медицине и гигиенических системах.

SUS420: согласование обработки с термообработкой

В отожжённом состоянии (~HRC20) SUS420 обрабатывается достаточно уверенно; после закалки до HRC50+ становится необходимым шлифование или твёрдое точение с использованием керамики/CBN. Типичный маршрут: черновая + получистовая обработка в отожжённом состоянии → термообработка → чистовое шлифование или твёрдое точение. Такой подход часто применяется для медицинского инструмента, лезвий и высокоточных износостойких деталей.

Решения по финишной и последующей обработке деталей из нержавеющей стали

Механическая финишная обработка: дробеструйная, полирование, шлифование щёткой

Мы предлагаем широкий спектр механических финишных обработок:

Дробеструйная (или шариковая) обработка для получения равномерной матовой текстуры и маскировки дефектов.

Механическое полирование для зеркальных поверхностей, гигиенических требований или премиального внешнего вида.

Шлифование щёткой для направленной риски, повышенной стойкости к истиранию и современного «индустриального» дизайна.

Для деталей, контактирующих с пищей и санитарных компонентов мы строго контролируем шероховатость, чтобы обеспечить чистоту и соответствие нормативам.

Химические обработки: пассивация, электрополирование, окрашивание

Пассивация удаляет свободное железо и усиливает хромсодержащую пассивную плёнку, возвращая стали оптимальную коррозионную стойкость. Электрополирование улучшает как гладкость, так и коррозионную стойкость, особенно на сложных геометриях. Химическое окрашивание и технологии оксидных плёнок обеспечивают стойкие декоративные покрытия для архитектурных и видимых элементов.

Передовые технологии обработки поверхности: PVD-покрытия и высокоуровневое электрополирование

Для повышенных требований к износостойкости или внешнему виду мы наносим на нержавеющую сталь PVD-покрытия (например, TiN, TiCN, DLC), повышающие твёрдость, снижающие трение и придающие стабильный цвет. Высококачественное электрополирование широко применяется для медицинских и пищевых компонентов, где критически важны сверхгладкие и легко очищаемые поверхности.

Ключевые элементы контроля качества при обработке нержавеющей стали на ЧПУ

Размерная и геометрическая точность

Для компенсации термических дрейфов и упругих деформаций мы:

Применяем поэтапную обработку с контролируемыми припусками.

Стабилизируем температуру станков, СОЖ и окружающей среды.

Используем измерения в процессе (щупы, калибры, CMM) и корректировки.

Для ультрапрецизионных деталей проводим снятие напряжений или искусственное старение до окончательной чистовой обработки.

Сохранность поверхности: не только цифры шероховатости

Для ответственных деталей мы оцениваем целостность поверхности по следующим критериям:

Измерение шероховатости в соответствии с функциональными требованиями.

Микроскопический контроль на наличие надрывов, наплывов, микротрещин и размазанного металла.

Металлографические исследования для подтверждения отсутствия неблагоприятных фазовых превращений и структурных изменений.

Это особенно важно для деталей, применяемых в химической промышленности, напорных системах и медицинской среде.

Подтверждение коррозионной стойкости

Если из-за мехобработки, загрязнений или некорректной финишной обработки коррозионная стойкость снижается, под угрозой оказывается весь замысел конструктора. Мы проверяем её с помощью:

Испытаний в нейтральном соляном тумане для сопоставимого сравнения.

Визуального и микроскопического контроля после воздействия среды.

Электрохимических испытаний (например, определение потенциала питтинга) для особо критичных компонентов.

При возникновении проблем мы прослеживаем всю цепочку — от сертификатов материала и этапов обработки до финишных операций — и устраняем корневую причину.

Типичные области применения деталей из нержавеющей стали, обработанных на ЧПУ

Медицинская отрасль: хирургический инструмент, имплантаты, корпуса

В медицинской промышленности нержавеющая сталь широко применяется благодаря биосовместимости, коррозионной стойкости и устойчивости к стерилизации. Мы производим высокоточные щипцы, ножницы, элементы сверлильных систем и корпуса с жёсткими допусками и качественной чистотой поверхностей. Для долгосрочных имплантатов мы используем низкоуглеродистые и высокочистые марки, такие как 316L, совмещая их с тщательно отработанными стратегиями обработки и финишной доводки.

Пищевая промышленность: гигиенические компоненты и системы

Для пищевой и напиточной отрасли мы изготавливаем направляющие, клапаны, корпуса насосов и резервуары, которые должны быть гигиеничными, легко очищаемыми и не иметь застойных зон. Мы тщательно контролируем сварные швы, переходы и шероховатость поверхности, чтобы удовлетворить санитарные нормы и свести к минимуму риск загрязнения.

Химическая и морская отрасли: конструкции с критичной коррозионной стойкостью

В химических производствах и офшорных/морских условиях мы изготавливаем корпуса насосов, элементы клапанов, коллекторы и трубные соединения из SUS316 и дуплексных нержавеющих сталей. Детали часто имеют сложные внутренние каналы и уплотнительные поверхности, где наши возможности многоосевой обработки на ЧПУ и современный контроль измерений обеспечивают одновременно точность и долговечность.

Почему стоит выбрать Neway для обработки нержавеющей стали на ЧПУ

В компании Neway мы никогда не относимся к нержавеющей стали как к «ещё одному материалу». Мы объединяем глубокое понимание металлургии, оптимизированные библиотеки инструмента, проверенные базы режимов резания и надёжную систему качества, чтобы обеспечивать стабильный результат как в прототипах, так и в серийном производстве. Наши внутренние базы данных содержат рекомендации по процессам для стандартных и специальных марок нержавеющих сталей, что позволяет нам быстро задавать надёжные окна режимов для ваших деталей.

Благодаря интегрированному формату «one-stop service» мы сопровождаем вас на всём пути: от выбора материала и DFM-анализа до обработки на ЧПУ, термообработки, финишной обработки поверхности и финального контроля с документацией. Нужны ли вам несколько сложных прототипов или стабильное крупносерийное производство — наша система выстроена так, чтобы поставлять детали, которые одновременно соответствуют чертежам и реальным условиям эксплуатации.

FAQ

Как выбрать подходящую марку нержавеющей стали для моего применения?

Какие типичные ошибки при обработке нержавеющей стали следует избегать?

Как пассивация и электрополирование повышают коррозионную стойкость нержавеющей стали?

Какие меры предосторожности необходимы при обработке тонкостенных деталей из нержавеющей стали?

Как Neway обеспечивает стабильное качество при обработке нержавеющей стали?