What specific expertise does Neway have in machining zirconia and alumina ceramics?

Advanced Capabilities for Demanding Ceramic Components

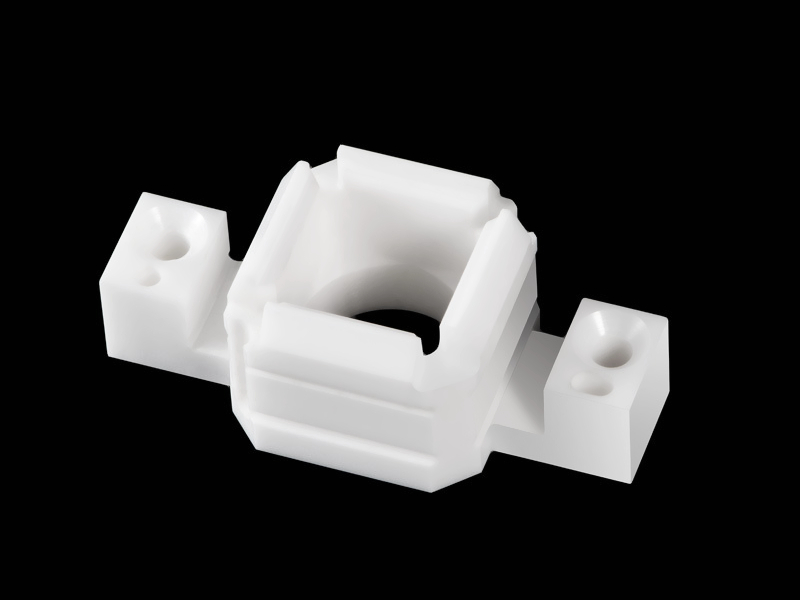

Neway possesses specialized expertise in the precision CNC Machining of Ceramics, particularly with advanced materials such as zirconia (ZrO₂) and Alumina (Al₂O₃). Our experience is rooted in understanding the unique properties of these ceramics, which include high hardness, excellent wear resistance, and thermal stability, as well as inherent brittleness that requires meticulous handling. We have developed proprietary processes to overcome these challenges, ensuring the production of high-integrity, complex ceramic parts that meet the most stringent tolerances and surface finish requirements.

Specialized Manufacturing Processes for Ceramic Materials

Machining ceramics is fundamentally different from machining metals. Our expertise is demonstrated through the application of specific, controlled processes. We utilize advanced CNC Grinding Service as a primary method, employing diamond-impregnated wheels to achieve precise geometries and fine surface finishes. For complex, multi-faceted components, our Multi-Axis Machining Service allows for simultaneous operations on multiple part faces, reducing setup time and ensuring exceptional feature relationship accuracy. Furthermore, we leverage non-conventional methods, such as Electrical Discharge Machining (EDM), for conductive ceramics and apply the principles of Precision Machining to every project, ensuring that each component adheres to the specified dimensional and geometric tolerances without compromise.

Material-Specific Knowledge and Application

Our expertise is granular, extending to the specific behaviors of each ceramic grade. For Zirconia, we capitalize on its high fracture toughness and transformation toughening mechanism. This allows us to machine thinner walls and more delicate features than might be possible with other advanced ceramics. For Alumina, we tailor our processes to its extreme hardness and excellent electrical insulation properties, often machining components for insulative and wear-resistant applications. Our material knowledge also encompasses other technical ceramics, such as Silicon Carbide (SiC), for even more extreme environments. This specialization is supported by our work with high-performance alloys, providing us with a comprehensive understanding of materials science that benefits all our Superalloy CNC Machining Service and ceramic projects.

Industry-Specific Solutions and Post-Processing

Neway's ceramic machining capabilities are critical across several high-tech industries. In the Medical Device sector, we produce biocompatible zirconia components for surgical tools and implants. For Industrial Equipment manufacturers, we machine alumina wear parts, seals, and nozzles that extend equipment life. The Aerospace and Aviation industry relies on our ability to produce robust, heat-resistant ceramic components for sensors and insulation. To enhance the functionality of these parts, we offer specialized post-processing services, including precise Sandblasting for CNC components to achieve a uniform matte finish and controlled CNC Part Polishing to achieve micron-level surface smoothness, resulting in reduced friction and improved cleanliness.

Commitment to Precision and Quality

Our entire workflow, from initial material selection to final inspection, is governed by a rigorous quality management system. We understand that a ceramic component's performance is directly tied to its manufacturing precision. Every part we produce is verified to ensure it meets or exceeds customer specifications, solidifying our reputation as a trusted supplier for mission-critical ceramic components.