Serviço de impressão 3D em cerâmica | Alumina, Zircônia, Carbeto de silício

Introdução: Rompendo os Limites Geométricos da Fabricação Cerâmica Tradicional

Introdução: Rompendo os Limites Geométricos da Fabricação Cerâmica Tradicional

Na fabricação de alto nível, as cerâmicas de engenharia são materiais essenciais para ambientes extremos graças à sua excelente resistência a altas temperaturas, à corrosão, à sua elevada dureza e às excelentes propriedades de isolamento elétrico. No entanto, métodos tradicionais de fabricação cerâmica, como prensagem a seco e colagem por barbotina (slip casting), apresentam limitações claras quando se trata de produzir geometrias complexas: elevado custo de moldes, longos prazos de fabrico e grande dificuldade para obter cavidades internas, estruturas porosas e outros designs inovadores. Esses desafios impulsionaram diretamente o rápido desenvolvimento das tecnologias de manufatura aditiva cerâmica. Hoje, a impressão 3D em cerâmica está a libertar-se das restrições dos processos convencionais e a oferecer uma liberdade de design sem precedentes para componentes cerâmicos de alto desempenho.

Principais Tecnologias de Impressão 3D em Cerâmica: Estereolitografia (SLA) e Binder Jetting

A impressão 3D em cerâmica baseia-se principalmente em duas tecnologias nucleares, cada uma com características distintas, concebidas para responder a diferentes necessidades de aplicação.

Estereolitografia cerâmica (SLA) utiliza uma pasta de resina fotossensível carregada com pó cerâmico como matéria-prima. Durante a impressão, um laser UV varre seletivamente a superfície da pasta de acordo com a geometria da secção transversal pré-definida, curando a resina em regiões específicas e ligando assim as partículas cerâmicas. Esse processo camada a camada continua até formar um “corpo verde” completo. As principais vantagens desta tecnologia são a altíssima precisão dimensional e a excelente qualidade de superfície, sendo particularmente adequada para estruturas complexas com detalhes finos.

A tecnologia de binder jetting utiliza pó cerâmico seco como matéria-prima. A cabeça de impressão deposita seletivamente um ligante líquido sobre o leito de pó, unindo as partículas cerâmicas camada a camada até formar a peça. Uma grande vantagem desta tecnologia é não exigir estruturas de suporte, além de apresentar velocidade de impressão relativamente elevada, o que a torna mais adequada para componentes de médio e grande porte.

É importante salientar que a impressão 3D em cerâmica é, em essência, diferente da Impressão 3D em metal ou plástico, tanto em materiais como em mecanismos de processo. O “corpo verde” cerâmico impresso possui resistência relativamente baixa e deve passar por etapas de pós-processamento complexas para se tornar uma peça final totalmente densa.

Análise Detalhada de Três Cerâmicas de Engenharia de Alto Desempenho

Na impressão 3D em cerâmica, três materiais destacam-se pelas suas vantagens de desempenho únicas.

As cerâmicas de alumina estão entre as cerâmicas de engenharia mais utilizadas. A Alumina (Al₂O₃) oferece alta dureza, excelente isolamento elétrico e grande estabilidade química, apresentando desempenho excecional em ambientes com desgaste, requisitos de isolamento e ambientes corrosivos. Componentes de alumina produzidos por impressão 3D são amplamente utilizados em isoladores eletrónicos, revestimentos resistentes ao desgaste e suportes para instrumentos médicos.

As cerâmicas de zircónia são conhecidas como “aço cerâmico” pelas suas propriedades mecânicas excecionais. A Zircónia (ZrO₂) utiliza o mecanismo de tenacificação por transformação para alcançar a mais elevada tenacidade à fratura e resistência à flexão entre os materiais cerâmicos, além de baixa condutividade térmica e biocompatibilidade. Estas características tornam-na um material ideal para implantes dentários, ferramentas de corte, vedantes de bombas e válvulas e componentes de células de combustível.

As cerâmicas de carboneto de silício representam o auge do desempenho em cerâmicas de engenharia. O Carboneto de Silício (SiC) apresenta condutividade térmica extremamente elevada, resistência a temperaturas muito altas (até e acima de 1600°C) e excelente resistência ao choque térmico, mantendo desempenho estável mesmo em ambientes extremos. Por isso, é insubstituível em aplicações como dispositivos para processos de semicondutores, bicos de foguete e permutadores de calor de alta temperatura.

Cinco Vantagens-Chave de Escolher a Impressão 3D em Cerâmica

A manufatura aditiva cerâmica traz benefícios revolucionários para a fabricação de alto nível, com vantagens centrais refletidas nos seguintes aspetos:

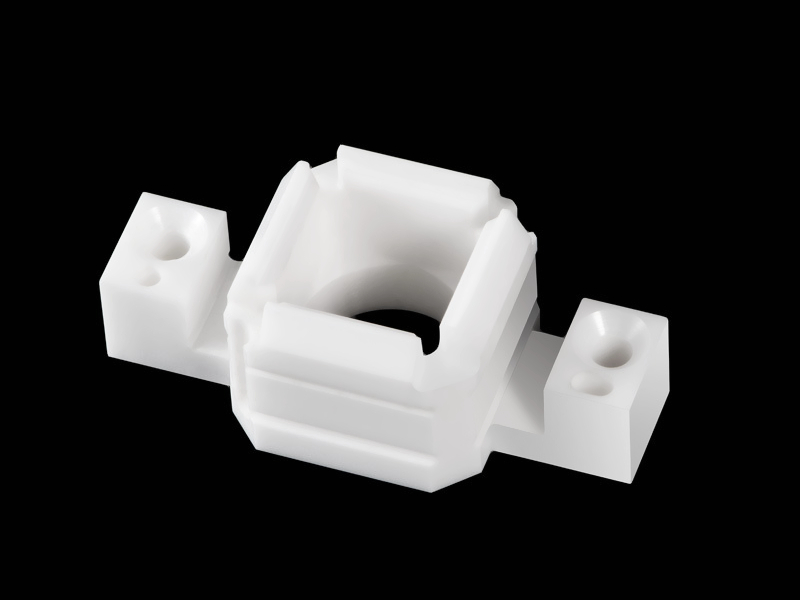

Liberdade geométrica incomparável é a maior vantagem da impressão 3D em cerâmica. Ela permite criar geometrias complexas, como estruturas porosas, canais internos e redes de paredes finas, extremamente difíceis ou impossíveis de alcançar com métodos tradicionais, abrindo novas possibilidades para a inovação em design.

Iteração rápida sem necessidade de ferramentas (tooling-free) acelera significativamente o desenvolvimento de produtos. Os projetistas podem passar diretamente de modelos CAD para a fase de Serviço de Prototipagem, validando rapidamente conceitos de design, o que é especialmente adequado para produtos personalizados e de baixo volume.

Excelente desempenho do material garante fiabilidade. Com parâmetros de processo otimizados e sinterização rigorosamente controlada, a densidade e as propriedades das peças impressas podem aproximar-se das cerâmicas fabricadas por processos convencionais.

Integração funcional melhora ainda mais a fiabilidade do produto. Ao integrar vários componentes numa única peça impressa, a impressão 3D em cerâmica reduz etapas de montagem e potenciais pontos de falha, melhorando o desempenho global do sistema.

Suporte à personalização e customização torna a impressão 3D em cerâmica particularmente adequada para necessidades específicas em áreas como medicina e pesquisa. Seja para Serviços de Fabricação em Baixo Volume ou peças únicas personalizadas, é possível implementar soluções a um custo razoável.

Do “Corpo Verde” à Peça Densa: Principais Etapas de Pós-Processamento na Impressão 3D em Cerâmica

O sucesso da impressão 3D em cerâmica depende fortemente do controlo de qualidade no pós-processamento. A desbinação (debinding) é a primeira etapa crítica, em que os ligantes orgânicos ou componentes de resina presentes na peça impressa são removidos através de aquecimento controlado, resultando num frágil “corpo castanho”. Esta etapa exige um controlo de temperatura extremamente rigoroso para evitar fissuras ou deformações.

A sinterização em alta temperatura é o processo central que determina o desempenho final da peça. A temperaturas significativamente superiores às da sinterização de metais (frequentemente acima de 1500°C), as partículas cerâmicas fundem-se por difusão, alcançando densificação e as propriedades mecânicas finais. Embora semelhante em princípio ao Tratamento Térmico para Peças Usinadas em CNC, os requisitos de controlo de temperatura e processo para cerâmicas são muito mais exigentes.

O acabamento e o processamento secundário garantem que as peças cumpram os requisitos de uso final. Componentes sinterizados podem necessitar de retificação de precisão para atingir as dimensões finais, para o que se pode recorrer ao Serviço de Retificação CNC. Para peças com requisitos especiais de superfície, o Serviço de Polimento de Peças CNC pode ser aplicado para alcançar o acabamento desejado.

Impressão 3D em Cerâmica vs. Fabricação Cerâmica Tradicional vs. Cerâmica Usinada em CNC

A seleção do processo adequado para peças cerâmicas exige uma avaliação abrangente das necessidades específicas do projeto.

Em comparação com os métodos tradicionais de fabricação cerâmica, a impressão 3D em cerâmica apresenta vantagens claras em custo de moldes, complexidade geométrica e tempo de produção. Isto é particularmente evidente na produção em baixo volume, onde a impressão 3D é significativamente mais económica.

Em comparação com o Serviço de Usinagem CNC de Cerâmica, cada abordagem tem os seus pontos fortes. A impressão 3D em cerâmica destaca-se na produção de formas extremamente complexas, com elevada utilização de material e sem desgaste de ferramentas. A usinagem CNC é mais adequada para geometrias relativamente simples que exigem precisão dimensional ultra-elevada e acabamento de superfície superior, embora envolva mais desperdício de material e custos de ferramenta mais altos.

Na prática, adotamos frequentemente uma estratégia de fabricação híbrida: usar impressão 3D para produzir pré-formas near-net-shape e, em seguida, aplicar Serviço de Usinagem de Precisão para acabamento fino nas superfícies críticas de montagem. Esta abordagem combinada aproveita as vantagens de ambas as tecnologias para obter peças finais de alta qualidade da forma mais económica possível.

Aplicações de Ponta: Como a Impressão 3D em Cerâmica Resolve Desafios da Fabricação de Alto Nível

A impressão 3D em cerâmica desempenha um papel cada vez mais importante em múltiplos setores de alta tecnologia.

Em Aeroespacial e Aviação, a impressão 3D em cerâmica é usada para produzir núcleos de pás de turbina leves e resistentes a altas temperaturas, radomes e invólucros para sensores de motores. Esses componentes mantêm desempenho estável em condições extremas, apoiando avanços na tecnologia aeroespacial.

No setor de Dispositivos Médicos, a biocompatibilidade das cerâmicas de zircónia torna-as um material ideal para implantes ortopédicos personalizados e restaurações dentárias porosas. Com a impressão 3D, os implantes podem ser adaptados à anatomia de cada paciente, melhorando significativamente os resultados clínicos.

Em Equipamentos Industriais, chuckes eletrostáticos em Nitreto de Silício (Si₃N₄) produzidos por impressão 3D em cerâmica são amplamente utilizados na fabricação de semicondutores, enquanto diversos componentes cerâmicos de válvulas resistentes à corrosão e ao desgaste garantem operação estável e de longa duração em ambientes industriais agressivos.

Capacidades e Compromisso da Neway em Impressão 3D em Cerâmica

Na Neway, estamos comprometidos em fornecer soluções de manufatura aditiva cerâmica altamente profissionais. Operamos equipamentos avançados de impressão 3D em cerâmica e fornos de desbinação e sinterização com controlo rigoroso, garantindo que cada peça cumpra os mais elevados padrões de qualidade. A nossa compreensão profunda dos materiais cerâmicos e o nosso amplo banco de dados de parâmetros de processo permitem-nos oferecer soluções de fabrico otimizadas para cada aplicação.

Oferecemos um Serviço One-Stop completo, desde consultoria de design e impressão até pós-processamento e inspeção final, garantindo que os clientes recebam suporte integral de ponta a ponta. Seja ao trabalhar com materiais de alta condutividade térmica, como Nitreto de Alumínio (AlN), seja ao produzir componentes com estruturas internas complexas, dispomos da capacidade técnica e da experiência necessárias.

Conclusão: Abrindo um Novo Capítulo na Fabricação de Peças Cerâmicas de Alto Desempenho

A impressão 3D em cerâmica está a revolucionar as possibilidades na fabricação de componentes cerâmicos de alto desempenho. Ao superar as limitações geométricas dos processos tradicionais, esta tecnologia está a abrir novos caminhos para inovação de produto e melhoria de desempenho. Nos setores aeroespacial, de dispositivos médicos, equipamentos industriais e outros campos avançados de manufatura, a manufatura aditiva cerâmica desempenha um papel cada vez mais vital.

À medida que a tecnologia amadurece e os sistemas de materiais evoluem, acreditamos que a impressão 3D em cerâmica demonstrará o seu valor em ainda mais aplicações. A Neway espera colaborar com engenheiros e designers de vários setores para explorar o potencial ilimitado da manufatura aditiva cerâmica e impulsionar a inovação tecnológica e a atualização industrial.