Ceramic

Material Introduction

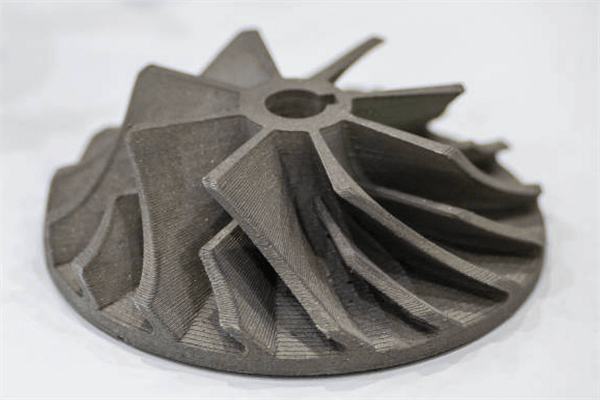

Ceramics for 3D printing provide a unique combination of extreme hardness, high temperature resistance, exceptional chemical stability, and excellent dielectric properties. Unlike metals and polymers, technical ceramics maintain their shape and mechanical integrity even when exposed to temperatures above 1,000–1,600°C, making them indispensable in harsh thermal, chemical, and electrical environments. Additive manufacturing methods, such as stereolithography, binder jetting, and advanced slurry-based printing, enable the creation of precise ceramic components with complex geometries, thin walls, internal channels, and fine surface detail. Common engineering ceramics include Zirconia, Alumina, Silicon Nitride, Silicon Carbide, and Boron Nitride. These materials are well-suited for aerospace thermal shields, semiconductor components, medical implants, precision instruments, and various advanced industrial systems.

International Names or Representative Ceramics

Region | Common Ceramics / Names |

|---|---|

USA | Zirconia, Alumina, SiC, Si₃N₄ |

Europe | Technical Ceramics, Advanced Ceramics |

China | 氧化锆, 氧化铝, 氮化硅, 碳化硅 |

Japan | Fine Ceramics, ZrO₂, Al₂O₃ |

Semiconductor Industry | Si₃N₄, SiC, BN |

Medical Field | Y-TZP Zirconia |

Alternative Material Options

Depending on design needs, ceramics can be replaced with several alternatives. When moderate temperature stability and high toughness are required, metals such as Titanium or Stainless Steel SUS316L offer easier machinability and better ductility. For electrical insulation, high-performance plastics such as PEEK or PI offer lighter weight and improved impact resistance. When requiring extreme wear resistance with some toughness, carbide-based metals or cobalt alloys such as Stellite are suitable. For thermal shock resistance, silicon nitride and aluminum nitride ceramics may be replaced by high-temperature nickel superalloys such as Inconel 625.

Design Purpose

Ceramic materials for additive manufacturing are engineered for environments where metals and polymers fail. Their purpose is to deliver ultra-high hardness, thermal resistance, chemical inertness, and electrical insulation in complex parts previously impossible to fabricate. 3D printed ceramics allow designers to integrate micro-channels, porous structures, intricate lattice geometries, or monolithic shapes for aerospace heat shields, medical prosthetics, semiconductor wafers, and specialty industrial components.

Chemical Composition (Alumina Example)

Component | Percentage (%) |

|---|---|

Al₂O₃ | 92–99+ |

SiO₂ | 0.1–2 |

MgO | 0.05–0.5 |

CaO | 0.05–0.3 |

Physical Properties

Property | Value |

|---|---|

Density | 3.5–6.0 g/cm³ (varies by ceramic) |

Melting Point | 1,800–2,600°C |

Thermal Conductivity | 5–200 W/m·K |

Electrical Resistivity | Very High |

Thermal Expansion | Low |

Mechanical Properties

Property | Value |

|---|---|

Hardness | Extremely High (1200–2000 HV) |

Flexural Strength | 300–1,200 MPa |

Compressive Strength | Very High |

Fracture Toughness | Low–Moderate |

Wear Resistance | Excellent |

Key Material Characteristics

Ceramics possess exclusive characteristics essential in many high-demand environments:

Exceptional hardness and wear resistance for high-friction or abrasive applications.

Ultra-high temperature resistance enabling stable performance above 1,000°C.

Chemically inert, resisting acids, bases, molten salts, and corrosive gases.

Superior dielectric insulation for electrical and RF components.

High compressive strength suitable for structural loads.

Low thermal expansion ensures dimensional stability in extreme temperature conditions.

Exceptional surface finish potential through precision sintering and post-processing.

Biocompatibility suitable for dental and orthopedic applications.

Ability to incorporate micro-channels for thermal management.

Long service life in chemically or thermally aggressive environments.

Processing Performance Across Manufacturing Methods

Ceramics behave differently from metals in additive manufacturing, requiring specialized processing:

Stereolithography-based ceramic printing enables the creation of high-resolution shapes using UV-cured ceramic slurry.

Binder Jetting creates large, complex green bodies that are later sintered for final strength.

LCM (Lithography-based Ceramic Manufacturing) enables the creation of ultra-fine details for medical or microfluidic devices.

Post-print sintering densifies the ceramic to near-theoretical density.

Machining after sintering is extremely challenging and typically requires CNC grinding or EDM to achieve precision.

Suitable for hybrid manufacturing when preforms are printed and final shapes are machined using precision machining.

Thermal shock sensitivity must be considered during printing and cooling.

Suitable and Common Post-Processing Methods

Ceramic 3D printed parts often undergo various finishing treatments:

Sintering to densify the printed green body.

Polishing to achieve extremely smooth surfaces.

CNC grinding for precision tolerances.

Laser finishing for micro-textures and fine adjustments.

Impregnation or glazing for improved surface strength and aesthetics.

Thermal treatments to stabilize microstructure.

Coating for improved wear resistance or dielectric performance.

Common Industries and Applications

Ceramic additive manufacturing is used across technology-driven sectors:

Aerospace thermal barriers, nozzles, and insulation tiles.

Semiconductor wafer carriers, insulators, and precision fixtures.

Medical, dental crowns, implants, and surgical tools.

Electronics components requiring dielectric insulation.

Energy and nuclear applications require extreme chemical resistance.

High-performance machinery with wear-prone components.

Optical and scientific equipment requiring high-dimensional precision.

When to Choose Ceramics for 3D Printing

Ceramic materials are ideal when:

High hardness and wear performance are mandatory.

Components must withstand temperatures of 1,000–2,000°C without deformation or oxidation.

Chemical resistance is required against acids, alkalis, and corrosive gases.

Electrical insulation is critical in high-voltage or RF applications.

Metal or plastic materials cannot withstand the operational environment.

Ultra-precise micro-feature geometries are required.

Long-term dimensional stability under thermal cycling is essential.

Components require a biocompatible, non-reactive material for use in medical or dental applications.

The application challenges machining, making additive manufacturing ideal for complex forms.