CNC मशीन किए गए पार्ट्स के लिए प्रिसिजन हाइट गेज इंस्पेक्शन

CNC क्वालिटी मैनेजमेंट में प्रिसीजन हाइट गेज़ की कोर भूमिका

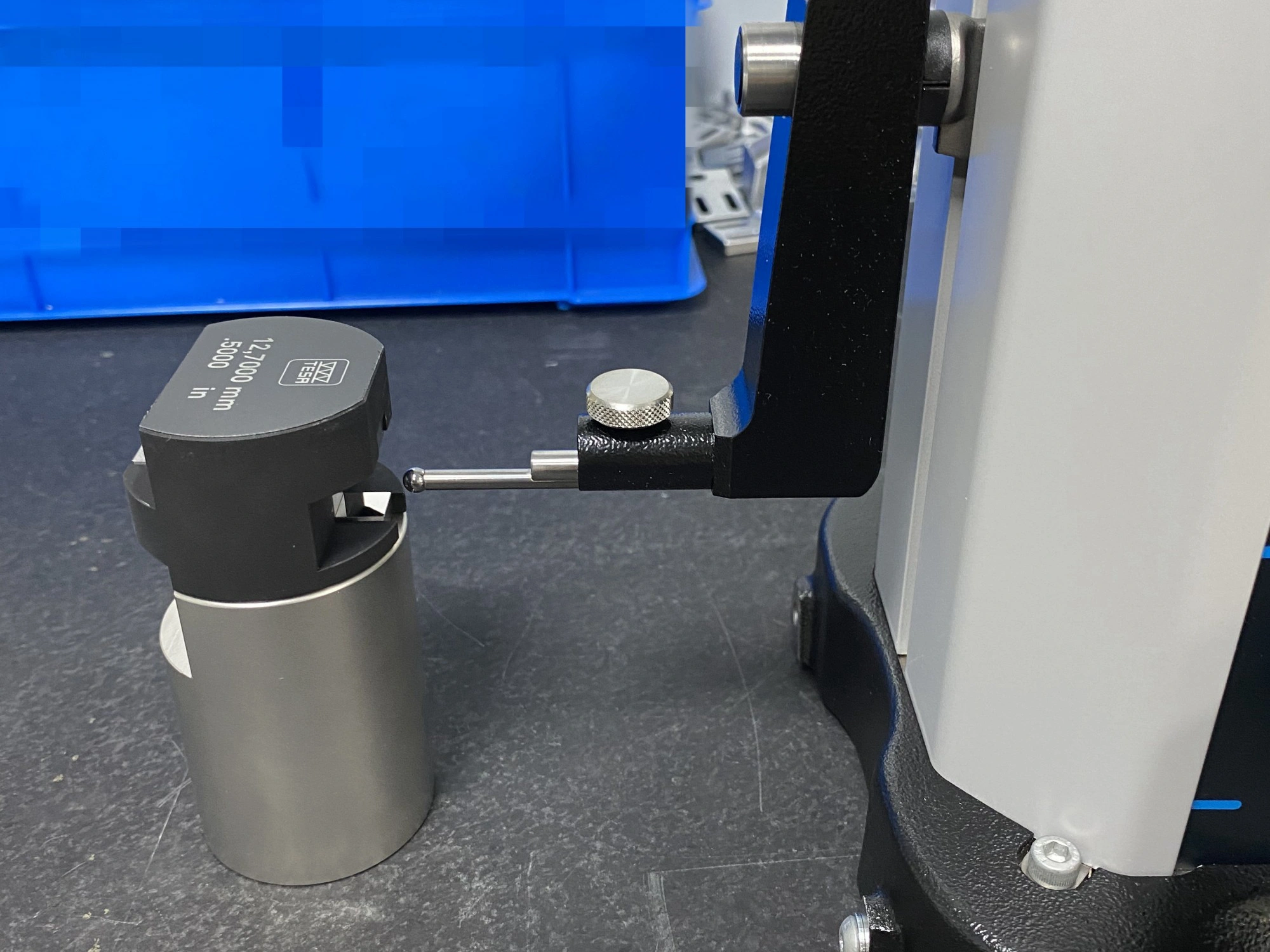

आधुनिक मैन्युफैक्चरिंग में प्रिसीजन हाइट गेज़ ऐसे डाइमेंशनल इंस्पेक्शन टूल हैं जो CNC-मशीन्ड पार्ट्स की क्वालिटी सुनिश्चित करने में अपरिहार्य भूमिका निभाते हैं। Neway की क्वालिटी कंट्रोल सिस्टम में, हाइट गेज इंस्पेक्शन ±0.005mm तक की टॉलरेंस आवश्यकताओं को हासिल करने के लिए एक बुनियादी सुरक्षा परत है। हमारे क्वालिटी इंजीनियर्स रोज़ाना Mitutoyo और TESA जैसे प्रतिष्ठित ब्रांडों के हाई-प्रिसीजन हाइट गेज़ का उपयोग करते हैं और उन्हें प्रिसीजन ग्रेनाइट सरफेस प्लेट के साथ मिलाकर फ़र्स्ट-आर्टिकल इंस्पेक्शन, इन-प्रोसेस इंस्पेक्शन और फाइनल इंस्पेक्शन के लिए इस्तेमाल करते हैं।

वास्तविक इंस्पेक्शन में, हम मास प्रोडक्शन के दौरान हाइट गेज परफॉर्मेंस की स्थिरता पर विशेष ध्यान देते हैं। सामान्य ऑटोमोटिव इंजन कंपोनेंट्स का उदाहरण लें—हाइट गेज सिलिंडर हेड की फ्लैटनैस, हाइट डाइमेंशन्स और पोज़िशनल टॉलरेंस को तेज़ और सटीक रूप से माप सकता है। एयरोस्पेस सेक्टर में उपयोग होने वाले एल्युमिनियम 6061-T6 पार्ट्स के लिए, हाइट गेज इंस्पेक्शन असेंबली इंटरचेंजएबिलिटी सुनिश्चित करने का एक महत्वपूर्ण चरण है।

डिजिटल हाइट गेज़ का कार्य सिद्धांत और एक्युरेसी ग्रेड

डिजिटल हाइट गेज़ प्रिसीजन ग्रेटिंग (स्केल) माप प्रणाली का उपयोग करते हैं, जिसमें सेंसर मैकेनिकल डिस्प्लेसमेंट को डिजिटल सिग्नल में परिवर्तित करते हैं और इस प्रकार हाई-एक्युरेसी डाइमेंशनल मेज़रमेंट हासिल होती है। Neway की क्वालिटी लेबोरेटरी में लगे डिजिटल हाइट गेज़ की एक्युरेसी ±0.001mm से ±0.005mm तक के ग्रेड को कवर करती है, जो अलग-अलग प्रिसीजन लेवल वाले पार्ट्स की इंस्पेक्शन आवश्यकताओं को पूरा करती है। हमारे इंस्पेक्शन इंजीनियर्स प्रोफ़ेशनल ट्रेनिंग से लैस हैं और स्टेनलेस स्टील 316L और टाइटेनियम अलॉय कंपोनेंट्स की विशेषताओं के आधार पर उपयुक्त माप बल और मेज़रमेंट स्ट्रेटेजी चुन सकते हैं।

व्यावहारिक अनुप्रयोगों में हम तापमान क्षतिपूर्ति (टेम्परेचर कम्पेन्सेशन) पर विशेष ज़ोर देते हैं। जब इंस्पेक्शन वातावरण मानक 20°C से विचलित होता है, तो हाइट गेज स्वतः तापमान क्षतिपूर्ति करता है, ताकि माप की सटीकता बनी रहे। यह फ़ंक्शन विशेष रूप से बड़े एयरोस्पेस कंपोनेंट्स की इंस्पेक्शन के दौरान महत्वपूर्ण हो जाता है, जहाँ मटेरियल के थर्मल एक्सपैंशन कोएफ़िशिएंट्स माप परिणामों पर उल्लेखनीय प्रभाव डाल सकते हैं।

पाँच-चरणीय इम्प्लीमेंटेशन स्टैंडर्ड: रेफरेंस से लेकर डेटा रिकॉर्डिंग तक

Neway ने हाइट गेज इंस्पेक्शन के लिए एक सख्त पाँच-चरणीय इम्प्लीमेंटेशन स्टैंडर्ड स्थापित किया है, ताकि प्रक्रिया का स्टैंडर्डाइज़ेशन और रिपीटेबिलिटी सुनिश्चित की जा सके। पहला चरण है रेफरेंस सरफेस स्थापित करना—इसमें प्रिसीजन ग्रेनाइट सरफेस प्लेट को माप रेफरेंस के रूप में इस्तेमाल किया जाता है, ताकि वर्कपीस प्लेसमेंट की फ्लैटनैस और पैरालेलिज़्म सुनिश्चित हो सके। दूसरा चरण है इंस्ट्रूमेंट कैलिब्रेशन, जिसमें गेज ब्लॉक्स का उपयोग ज़ीरो सेटिंग और हाइट गेज की एक्युरेसी वेरिफ़िकेशन के लिए किया जाता है।

तीसरा चरण है मेज़रमेंट प्रोग्राम का विकास। मल्टी-एक्सिस CNC मशीन्ड जटिल ज्योमेट्री वाले पार्ट्स के लिए, हम उचित मेज़रमेंट पाथ और माप बिंदुओं के वितरण को परिभाषित करते हैं। चौथा चरण है वास्तविक माप, जिसे क्वालिटी प्लान में निर्दिष्ट सैम्पलिंग फ़्रीक्वेंसी के अनुसार निष्पादित किया जाता है। पाँचवाँ चरण है डेटा रिकॉर्डिंग और विश्लेषण, जिसमें सभी परिणाम क्वालिटी मैनेजमेंट सिस्टम में एंट्री किए जाते हैं और एक पूर्ण डाइमेंशनल इंस्पेक्शन रिपोर्ट जनरेट की जाती है।

टिपिकल मेज़रमेंट केस विश्लेषण (प्लेन डिस्टेंस / होल डेप्थ / स्टेप हाइट)

मेडिकल डिवाइसेज़ के मैन्युफैक्चरिंग में, हम सर्जिकल इंस्ट्रूमेंट्स के कई क्रिटिकल डाइमेंशन्स की इंस्पेक्शन के लिए हाइट गेज़ का उपयोग करते हैं। ऑर्थोपेडिक इम्प्लांट्स का उदाहरण लें—जो मेडिकल डिवाइस मैन्युफैक्चरिंग मानकों के अनुरूप बने होते हैं—हम स्टेप हाइट, प्लेटफ़ॉर्म फ्लैटनैस और होल डेप्थ मापते हैं, ताकि सटीक और विश्वसनीय परिणाम सुनिश्चित किए जा सकें। ये डाइमेंशन्स सीधे सर्जिकल परफॉर्मेंस और रोगी की सुरक्षा को प्रभावित करते हैं।

कम्युनिकेशन उपकरणों में उपयोग होने वाले एनक्लोज़र के लिए, हाइट गेज़ मुख्य रूप से माउंटिंग सरफेस की को-प्लानैरिटी और स्क्रू बॉस की हाइट कंसिस्टेंसी मापने के लिए इस्तेमाल होते हैं। हम ग्रिड मेज़रमेंट मेथड अपनाते हैं, जिसमें पार्ट की सतह पर 25 माप बिंदु लेआउट किए जाते हैं, ताकि फ्लैटनैस क्वालिटी का व्यापक मूल्यांकन किया जा सके। इस सख्त विधि के माध्यम से, हम समस्याओं की समय पर पहचान कर पाते हैं और CNC प्रिसीजन मशी닝 सेवाओं की टीम को प्रोसेस एडजस्टमेंट के लिए तुरंत फ़ीडबैक दे सकते हैं।

आउट-ऑफ़-टॉलरेंस विश्लेषण और प्रोसेस करेक्टिव व प्रिवेंटिव उपाय

जब हाइट गेज से आउट-ऑफ़-टॉलरेंस कंडीशन डिटेक्ट होती है, तो Neway के क्वालिटी इंजीनियर्स तुरंत रूट कॉज़ एनालिसिस प्रक्रिया शुरू करते हैं। सबसे पहले वे मेज़रमेंट डेटा के वितरण पैटर्न का विश्लेषण करते हैं, ताकि यह निर्धारित किया जा सके कि डेविएशन सिस्टमैटिक एरर के कारण है या रैंडम एरर के कारण। इसके बाद वे मशी닝 प्रोसेस में संभावित फैक्टर्स—जैसे टूल वियर, फ़िक्स्चर लूज़नेस या थर्मल डिफ़ॉर्मेशन—तक ट्रेसिंग करते हैं और संबंधित करेक्टिव मेज़र्स तैयार करते हैं।

हमने एक व्यापक क्वालिटी वार्निंग मैकेनिज़्म स्थापित किया है। जब हाइट गेज मेज़रमेंट डेटा में ट्रेंडिंग शिफ्ट दिखाई देती है, तो सिस्टम ऑटोमैटिक रूप से अलर्ट जारी करता है। यह प्रिवेंटिव क्वालिटी कंट्रोल अप्रोच ऑटोमोटिव इंजन कंपोनेंट्स के मास प्रोडक्शन में विशेष रूप से महत्वपूर्ण है और बड़े पैमाने पर क्वालिटी समस्याओं से प्रभावी रूप से बचाती है।

CMM के साथ इंटीग्रेटेड कॉम्पोज़िट इंस्पेक्शन स्कीम

जटिल पार्ट्स के लिए, Neway हाइट गेज़ और कोऑर्डिनेट मेज़रिंग मशीन (CMM) को एकीकृत करते हुए कॉम्पोज़िट इंस्पेक्शन सॉल्यूशन अपनाता है। हाइट गेज़ पारंपरिक डाइमेंशन्स की तेज़ इंस्पेक्शन के लिए जिम्मेदार होता है, जबकि डाइमेंशनल इंस्पेक्शन रिपोर्ट में शामिल जटिल ज्योमेट्रिक टॉलरेंस CMM द्वारा वेरिफ़ाई किए जाते हैं। यह वर्क डिविज़न इंस्पेक्शन एफिशिएंसी के साथ-साथ परिणामों की विश्वसनीयता भी सुनिश्चित करती है।

वास्तविक उत्पादन में, हम पहले हाइट गेज़ के माध्यम से 100% इंस्पेक्शन करते हैं, उसके बाद सैम्पलिंग प्लान के अनुरूप CMM वेरिफ़िकेशन करते हैं। यह डुअल-अशोरेंस मैकेनिज़्म एयरोस्पेस कंपोनेंट्स की क्वालिटी कंट्रोल के लिए विशेष रूप से उपयुक्त है, यह सुनिश्चित करते हुए कि प्रत्येक पार्ट डिज़ाइन स्पेसिफ़िकेशन्स और सुरक्षा आवश्यकताओं दोनों को पूरा करता है।

इंडस्ट्री-स्पेसिफिक आवश्यकताएँ (एयरोस्पेस / मेडिकल इम्प्लांट्स)

अलग-अलग उद्योग हाइट गेज इंस्पेक्शन पर अपनी विशिष्ट आवश्यकताएँ थोपते हैं। एयरोस्पेस में, इंस्पेक्शन प्रोसेस की ट्रेसबिलिटी पर विशेष ज़ोर दिया जाता है—हर मेज़रमेंट परिणाम को संबंधित पार्ट के सीरियल नंबर, उपयोग किए गए इंस्पेक्शन उपकरण और ऑपरेटर से लिंक किया जाना चाहिए। मेडिकल सेक्टर में, विशेष रूप से मेडिकल डिवाइस मैन्युफैक्चरिंग में, इंस्पेक्शन वातावरण की क्लीनलीनेस और बायोकम्पैटिबिलिटी वेरिफ़िकेशन पर अधिक ध्यान दिया जाता है।

इम्प्लांट कंपोनेंट्स के लिए, हम तापमान और आर्द्रता नियंत्रित क्लीनरूम में हाइट गेज इंस्पेक्शन करते हैं, ताकि पर्यावरणीय प्रभावों का माप परिणामों पर न्यूनतम प्रभाव हो। हम माइक्रो-ज्योमेट्रिक सतह फीचर्स पर भी विशेष ध्यान देते हैं, क्योंकि वे सीधे ऑसियोइंटीग्रेशन परफॉर्मेंस को प्रभावित करते हैं। इन सख्त स्पेशल आवश्यकताओं का पालन करके, Neway के स्टेनलेस स्टील 316L इम्प्लांट्स सबसे कठोर मेडिकल मानकों को पूरा करते हैं।

Neway का इंस्पेक्शन उपकरण और क्वालिटी कमिटमेंट

Neway ने राष्ट्रीय मानकों के अनुरूप एक मेट्रोलॉजी लेबोरेटरी में निवेश किया है, जो विभिन्न हाई-प्रिसीजन इंस्पेक्शन इंस्ट्रूमेंट्स से सुसज्जित है। हमारा हाइट गेज इंस्पेक्शन एरिया स्वतंत्र एंटी-वाइब्रेशन फ़ाउंडेशन पर बनाया गया है और सख्त तापमान और आर्द्रता नियंत्रित है, जिससे माप के परिणाम सटीक और विश्वसनीय बने रहते हैं। सभी इंस्पेक्शन उपकरणों की नियमित रूप से अधिकृत संस्थानों द्वारा कैलिब्रेशन की जाती है, ताकि माप मानों की ट्रेसबिलिटी और एक्युरेसी सुनिश्चित हो सके।

हम हर ग्राहक को सटीक, पूर्ण और विश्वसनीय इंस्पेक्शन डेटा प्रदान करने के लिए प्रतिबद्ध हैं। चाहे वह स्मॉल-बैच प्रोटोटाइपिंग हो या बड़े पैमाने की CNC प्रिसीजन मशी닝 सेवाएँ, हम समान इंस्पेक्शन स्टैंडर्ड और क्वालिटी आवश्यकताओं को लागू करते हैं। सख्त हाइट गेज इंस्पेक्शन और सहायक मेज़रमेंट मेथड्स के माध्यम से हम सुनिश्चित करते हैं कि हर डिलीवर किया गया पार्ट हमारे क्वालिटी कमिटमेंट्स को पूरा करे।