3D-печать из термопластов | Multi Jet Fusion (MJF)

Введение: как MJF меняет правила игры в малосерийном производстве пластиковых деталей

В стремительно меняющемся мире современного производства спрос на пластиковые детали становится всё более разнообразным и индивидуализированным. Традиционное литьё под давлением обладает непревзойдённым преимуществом по себестоимости при массовом выпуске, однако явно уступает, когда речь идёт о малосерийном производстве, быстрой итерации и изготовлении сложных геометрий. Именно здесь технология Multi Jet Fusion (MJF) демонстрирует свою уникальную ценность. Как инженеры по аддитивному производству в Neway, мы ежедневно видим, как эта технология помогает заказчикам выходить за рамки классических процессов, существенно сокращать цикл разработки изделий и при этом сохранять превосходное качество деталей.

Основной принцип технологии MJF: высокоскоростное и точное планарное производство

Уникальность технологии Multi Jet Fusion заключается в её инновационном принципе работы. В отличие от традиционного послойного лазерного сканирования по точкам, MJF использует полноценный планарный метод построения. Процесс начинается с равномерного нанесения ультратонкого слоя порошка нейлона на платформу построения. Затем высокоточный печатающий модуль выборочно наносит на поверхность порошка два вида специальных агентов: связывающий (fusing agent) и контурирующий (detailing agent). Связывающий агент распыляется в тех зонах, где должно формироваться изделие, а контурирующий — по границам, чтобы чётко прорисовать кромки и предотвратить потерю точности из-за паразитного теплового воздействия.

После этого инфракрасные источники энергии равномерно нагревают весь слой порошка. Области, где присутствует связывающий агент, быстро поглощают тепло, частицы порошка нейлона расплавляются и сплавляются в плотную монолитную структуру. Процесс повторяется слой за слоем до полной отстройки детали. По сравнению с селективным лазерным спеканием (SLS), планарный принцип экспонирования в MJF даёт серьёзное преимущество по скорости построения, что делает технологию особенно подходящей для средних по объёму партий.

Основные материалы для MJF: высокие эксплуатационные свойства нейлонов

Подбор материалов для MJF сосредоточен в первую очередь вокруг высокопроизводительных нейлоновых композиций, каждая из которых имеет свои особенности. PA12 (нейлон 12) — наиболее широко используемый базовый материал. Он отличается оптимальным балансом механических характеристик, высокой химической стойкостью и отличной размерной стабильностью, что делает его универсальным выбором для большинства задач. PA11 выгодно выделяется повышенной ударной вязкостью и ударной прочностью, а также тем, что изготавливается из возобновляемого сырья, лучше соответствуя целям устойчивого развития.

Для применений, где необходимы повышенная жёсткость и термостойкость, оптимальным выбором является нейлон с наполнением стеклошариками (PA12 GB). Добавленные стеклянные микросферы не только повышают жёсткость и температуру теплового прогиба, но и существенно снижают усадку при формовании. Нейлон, армированный углеродным волокном, обеспечивает исключительную прочность, жёсткость и размерную стабильность, что делает его идеальным материалом для высоконагруженных конструктивных деталей. Благодаря этим высокопроизводительным материалам MJF по праву занимает особое место в области 3D-печати пластиков.

Шесть ключевых причин выбрать 3D-печать по технологии MJF

Технология MJF выгодно выделяется среди других аддитивных процессов своими уникальными преимуществами. Во-первых, выдающиеся механические характеристики деталей — один из её главных конкурентных плюсов. Благодаря планарному нагреву по всей площади слоя изделия, напечатанные MJF, обладают действительно изотропными свойствами: они демонстрируют сопоставимую прочность во всех направлениях.

Высокая производительность — ещё одно важное преимущество. По сравнению с традиционным точечным сканированием, планарный принцип построения в MJF обеспечивает существенно более высокие скорости печати. В реальных производственных условиях скорость MJF может в несколько раз превосходить другие технологии, что критично для срочных проектов заказчиков.

Превосходная точность и качество поверхности позволяют деталям MJF удовлетворять требованиям большинства промышленных применений. Технология обеспечивает хорошую проработку деталей и однородную текстуру поверхности, а изделия часто уже «с печи» соответствуют функциональным требованиям без сложных дополнительных операций. Важно и то, что MJF не требует создания поддержек, что не только повышает свободу проектирования, но и значительно сокращает время и стоимость постобработки.

С экономической точки зрения MJF фактически ломает традиционный барьер литья под давлением по минимальному тиражу для рентабельного производства. В диапазоне примерно от 50 до 5000 пластиковых деталей MJF зачастую является наиболее выгодным решением. Дополнительно до 80 % неиспользованного порошка в процессе MJF может быть переработано и повторно использовано, что ещё больше снижает себестоимость и отражает современный подход к устойчивому производству.

Постобработка и финишная отделка деталей MJF

Детали, произведённые по технологии MJF, могут быть дополнительно улучшены за счёт различных методов постобработки. Наиболее распространённой и базовой операцией является дробеструйная или абразивная обработка (media blasting), которая создаёт равномерную матовую поверхность по всему изделию. Для задач, где важен определённый цвет, мы предлагаем профессиональные услуги по окрашиванию, позволяющие получить стабильный чёрный оттенок и другие цветовые решения.

Благодаря процессам сглаживания можно существенно улучшить текстуру поверхности и снизить её пористость, тем самым повысив герметичность и чистоту. Если требуется особый внешний вид, услуги по окраске позволяют реализовать широкий спектр цветов и специальных эффектов, соответствующих требованиям бренда или эстетики продукта.

MJF и другие технологии пластиковой 3D-печати: детальное сравнение

При выборе подходящей технологии 3D-печати важно понимать, как MJF соотносится с другими процессами. В сравнении с SLS, MJF демонстрирует явные преимущества по скорости печати, себестоимости и качеству поверхности, особенно в сегменте средних по объёму партий. Хотя SLS может предлагать более широкий набор материалов, MJF выигрывает по эффективности производства и стабильности качества.

По сравнению с FDM, MJF обеспечивает лучшее сочетание точности, прочности и изотропии. Несмотря на то, что оборудование FDM зачастую дешевле, слабое сцепление между слоями и выраженные «ступеньки» слоёв ограничивают применимость FDM в ответственных функциональных деталях. Напротив, изделия MJF обладают равномерными механическими свойствами и более высокой культурой поверхности.

В сравнении со SLA детали, изготовленные методом MJF, отличаются более высокими механическими характеристиками, лучшей термостойкостью и долговременной стабильностью. SLA действительно превосходит по детализации и гладкости поверхности, но хрупкость и склонность многих фотополимерных смол к старению и желтению заметно ограничивают их применение в нагрузочных узлах.

Инновационные применения технологии MJF в различных отраслях

Технология MJF трансформирует подходы к производству в самых разных отраслях. В автомобильной промышленности она используется для изготовления функциональных прототипов, малосерийных кастомизированных деталей, а также кондукторов и приспособлений, обеспечивая быстрые и экономичные решения. Получаемые детали соответствуют строгим эксплуатационным требованиям, при этом значительно сокращаются сроки разработки.

Медицинская промышленность — ещё одно ключевое направление применения MJF. Через наши решения для производства медицинских изделий мы можем изготавливать высокоточные хирургические направляющие, сложные корпуса для медицинских приборов и персонализированные реабилитационные устройства. Наличие биосовместимых материалов ещё больше расширяет сферу применения технологии в медицине.

Сектор потребительских товаров также существенно выигрывает от внедрения MJF. Будь то корпуса электронных устройств, элементы спортивного инвентаря или детали бытовой техники, MJF обеспечивает высокое качество продукции. Благодаря нашим услугам по производству потребительских товаров компании могут быстрее воплощать концепты в реальные изделия и ускорять проверку спроса на рынке.

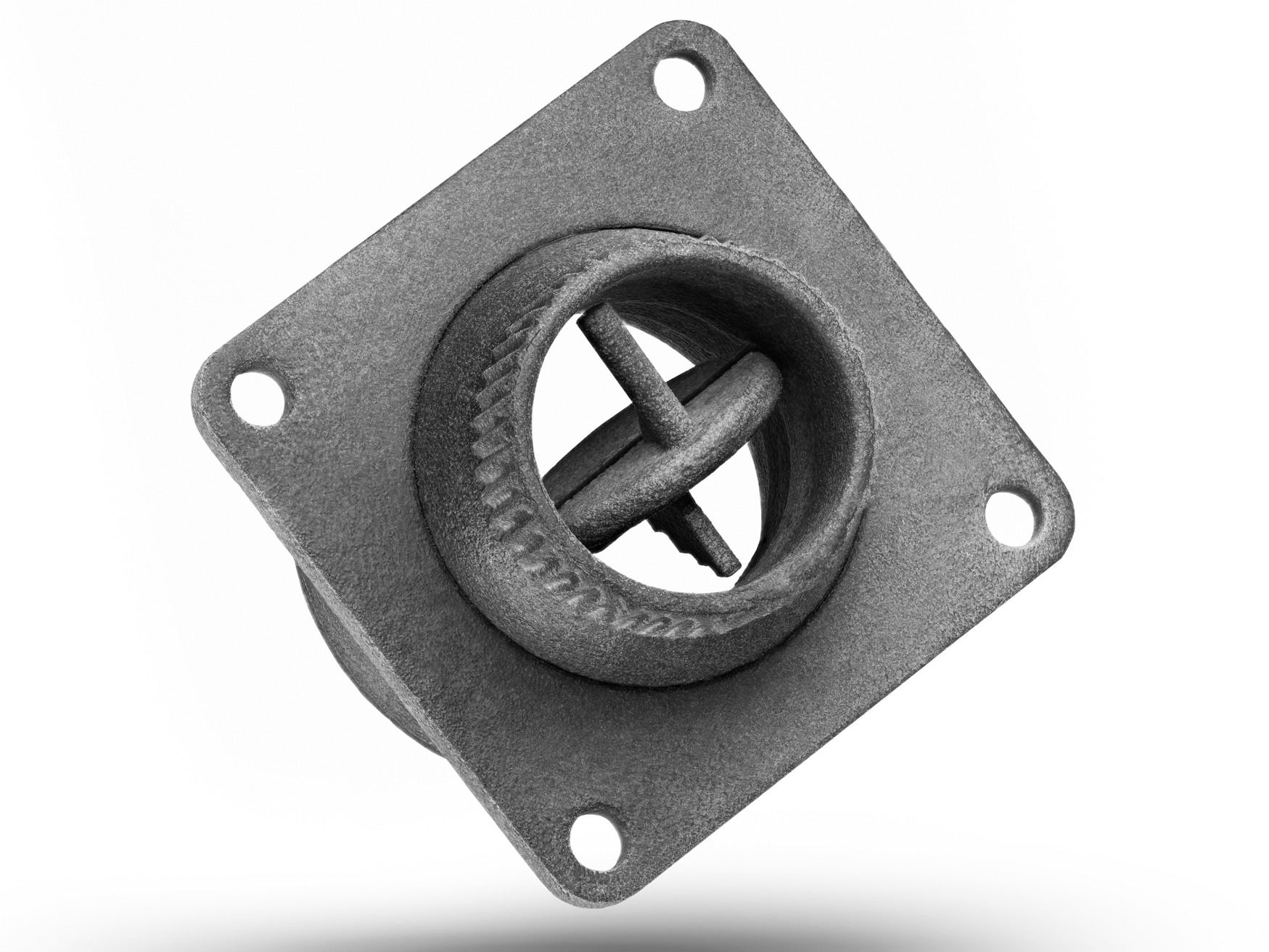

В промышленном секторе MJF используется для изготовления фитингов, шестерён, корпусов и разнообразного специализированного инструмента. Такие детали не только обладают высокой механической прочностью, но и удовлетворяют специфическим требованиям по условиям эксплуатации. Через наши решения для производства промышленного оборудования мы помогаем заказчикам решать сложные производственные задачи.

Преимущества MJF-услуг от Neway

В Neway мы нацелены на предоставление высококачественных услуг по 3D-печати MJF. Мы используем промышленные системы HP MJF, чтобы каждая деталь соответствовала самым строгим требованиям по качеству и повторяемости. Наша инженерная команда обладает глубокими знаниями в области материалов и оптимизации процессов, что позволяет сопровождать заказчиков на всех этапах — от доработки конструкции до выбора постобработки.

Мы предлагаем широкий спектр материалов — от стандартного PA12 до различных усиленных нейлонов — чтобы удовлетворить самые разные требования к применению. В части постобработки наши отлаженные маршруты и специализированное оборудование обеспечивают поставку деталей в оптимальном состоянии. Независимо от того, нужна ли вам быстрая разработка прототипов или малосерийное производство, мы обеспечиваем оперативную поддержку проекта и профессиональные рекомендации по технологии.

Рекомендации по проектированию: как оптимизировать детали под MJF

Чтобы максимально эффективно использовать преимущества MJF, крайне важно правильно оптимизировать конструкцию изделия. Для толщины стенок мы рекомендуем минимальное значение 0,8 мм и оптимальный диапазон 1,5–3 мм — это обеспечивает разумный баланс между прочностью и качеством построения.

Для отверстий и каналов мы советуем минимальный диаметр 1,5 мм и рекомендуем избегать чрезмерно глубоких элементов с большим отношением глубины к диаметру. При проектировании шарнирных соединений, защёлок и других сборочных элементов важно учитывать усталостное поведение материала и модуль упругости: щедрые скругления (галтели) в зонах перегиба способны существенно увеличить срок службы детали.

При разработке рельефных текстур и маркировок необходимо учитывать особенности технологии MJF. Мы рекомендуем минимальную высоту символов 0,8 мм и глубину не менее 0,3 мм для обеспечения хорошей читаемости. Для высокоточных функциональных поверхностей при необходимости можно применять вторичную механообработку с использованием многоосевой обработки.

Заключение: выберите MJF для эффективного и надёжного производства пластиковых деталей

Технология MJF переопределяет подход к малосерийному выпуску пластиковых изделий. Она не только обеспечивает оптимальный баланс между качеством продукта, производительностью и себестоимостью, но и даёт конструктору беспрецедентную свободу для создания инновационных решений. В Neway мы уверены, что эта технология и дальше будет открывать новые горизонты для производственной отрасли.

Мы приглашаем вас на практике оценить уникальные преимущества технологии MJF. Требуются ли вам функциональные прототипы, изготовленные методом 3D-печати нейлоном, или вы ищете эффективное дополнение к традиционным услугам по механообработке с ЧПУ, наша инженерная команда готова предоставить вам профессиональную поддержку. Давайте вместе исследовать безграничный потенциал аддитивного производства и воплощать самые смелые идеи в реальные изделия.

FAQs

Насколько долговечны детали, изготовленные по технологии MJF, при длительной эксплуатации?

Каков максимальный размер области построения для технологии MJF?

Можно ли использовать детали MJF в условиях повышенной температуры?

Каков коэффициент повторного использования материала в процессе MJF?

Какой уровень размерной точности могут обеспечивать детали, изготовленные по технологии MJF?