DFM для ЧПУ-обработки: 10 золотых правил оптимизации конструкции и снижения затрат

Введение

Эффективное проектирование с учётом технологичности (DFM) при мехобработке на ЧПУ играет ключевую роль в снижении стоимости, сокращении сроков и обеспечении стабильного качества деталей. Когда конструкторские решения согласованы с реальными возможностями станков, удаётся устранить лишние затраты ещё до запуска производства.

Ниже представлены 10 основных DFM-правил, которых стоит придерживаться инженерам при проектировании деталей для мехобработки с ЧПУ.

1. Избегайте необоснованно жёстких допусков

Допуски жёстче ±0,01 мм следует задавать только там, где это действительно критично для функции. Чрезмерно строгие допуски приводят к снижению скоростей резания, удорожанию контроля и повышенному риску брака. Применяйте их выборочно и чётко выделяйте размеры, критичные для работоспособности.

2. Проектируйте под стандартные размеры инструмента

Старайтесь использовать стандартные диаметры фрез и сверл (например, 3 мм, 6 мм, 12 мм), чтобы упростить CAM-программирование и сократить время переналадки инструмента. Избегайте «неудобных» радиусов и ширин пазов, которые требуют специального инструмента или множества проходов.

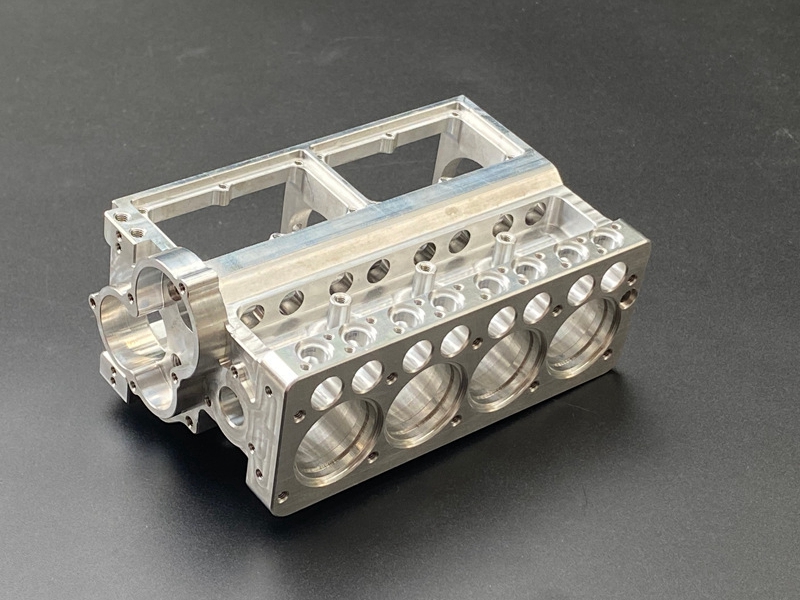

3. Обеспечивайте равномерную толщину стенок

Тонкие стенки (<0,8 мм для алюминия, <1,5 мм для стали) склонны к вибрациям, прогибам и короблению во время обработки. Стремитесь к равномерной толщине стенок и избегайте глубоких карманов с острыми внутренними углами.

4. Оптимизируйте отношение глубины отверстия к диаметру

Для сверлённых отверстий придерживайтесь соотношения глубины к диаметру ≤10:1. Слишком глубокие отверстия ускоряют износ инструмента и требуют специальных режимов глубокого сверления (peck drilling), что замедляет процесс и повышает стоимость.

5. Минимизируйте выборки поднутрения и острые внутренние углы

Поднутрения требуют специального инструмента или ЭЛО/EDM-обработки, что существенно увеличивает цену. Внутренние углы следует проектировать с радиусом не меньше диаметра инструмента, чтобы обеспечить плавные и эффективные траектории обработки.

6. Сокращайте количество переналадок и переустановок

Такая геометрия, которая может быть обработана за один установ, снижает время изготовления приспособлений и риск ошибок базирования. По возможности избегайте конструкции, требующей многих переориентаций детали для обработки противоположных сторон. Многосторонние детали особенно выигрышны при использовании многоосевой обработки.

7. Выбирайте хорошо обрабатываемые материалы

Выбирайте материалы, которые обеспечивают баланс между требуемыми механическими свойствами и хорошей обрабатываемостью. Например, алюминий 6061 обрабатывается проще и быстрее, чем титан или Inconel, для которых требуются сниженные скорости резания и дорогой инструмент.

8. Объединяйте элементы конструкции, где это возможно

Сокращение количества отдельных элементов (например, объединение близко расположенных отверстий или отказ от лишних боссов и выступов) уменьшает время обработки. Избегайте чисто декоративных деталей геометрии, если они не несут функциональной или конструктивной нагрузки.

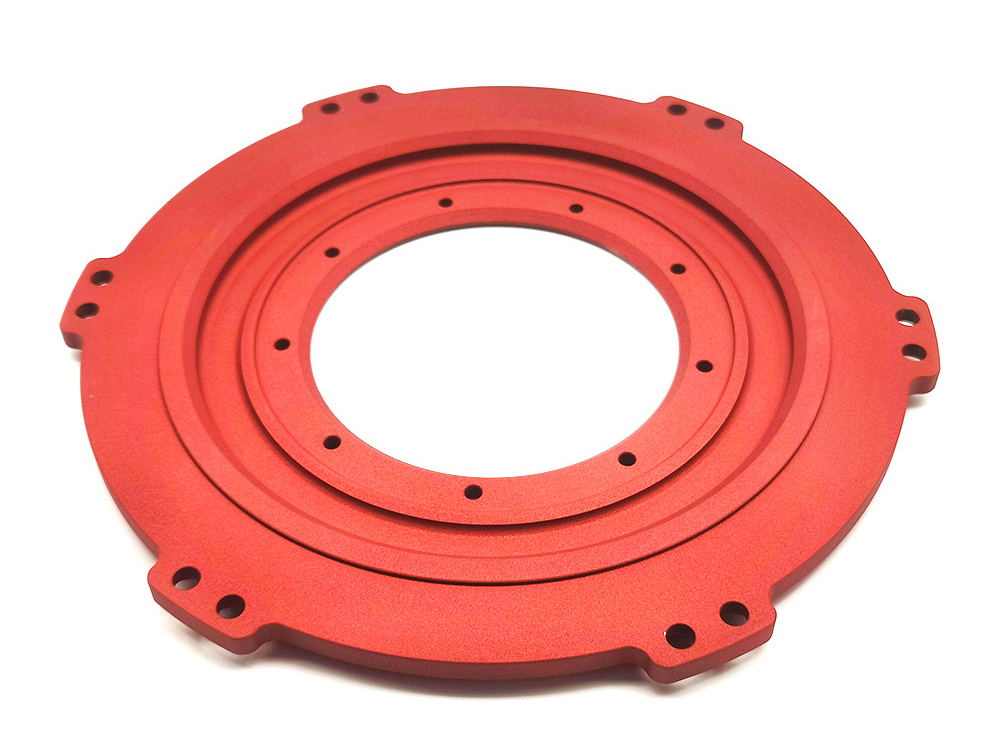

9. Планируйте требования к чистоте поверхности на раннем этапе

Разные виды финишной обработки требуют разных припусков и учёта толщины слоя. Например, если предполагается анодирование или электрополировка, допуски и плоскостность нужно задавать с учётом толщины покрытия и возможных изменений шероховатости.

10. Оформляйте чертежи полно и однозначно

2D-чертежи должны содержать все допуски, обозначения резьб, требования к шероховатости и указания по материалу. Избегайте двусмысленных примечаний. Важно, чтобы чертежи полностью соответствовали 3D-моделям и не оставляли пространства для разночтений между конструктором и производством.

Заключение

Применение принципов DFM ещё на стадии проектирования позволяет снизить стоимость обработки на ЧПУ, упростить производство и добиться более стабильного качества деталей. Для получения наилучшего результата важно тесно сотрудничать с опытными поставщиками услуг по мехобработке с ЧПУ, которые могут предоставить техническую обратную связь и рекомендации по технологичности уже на этапе расчёта стоимости.