5-Axis CNC Machining of Aluminum 6061 Heat Sinks for Huawei Communication Equipment

Project Background: High-Efficiency Heat Dissipation for Communication Devices

Huawei required a precision-engineered aluminum heat sink for its high-performance communication systems. The part needed to meet strict flatness and profile accuracy for maximum thermal contact while also conforming to Huawei’s stringent branding and corrosion resistance requirements. Neway was selected as the trusted partner to deliver a complete solution from milling to surface treatment.

Why Aluminum 6061 Was Selected for Heat Sink Structures

Aluminum 6061 offers an ideal combination of thermal conductivity, strength, and finish adaptability—key properties for mission-critical heat dissipation components.

Property | Value |

|---|---|

Thermal Conductivity | ~167 W/m·K |

Yield Strength | ≥240 MPa |

Surface Treatment Suitability | Excellent for sandblasting and powder coating |

Weight-to-Strength Ratio | High |

With its exceptional machinability and anodizing alternatives, Aluminum 6061 ensures precision and long-term reliability in telecom-grade components.

CNC Machining Process Breakdown

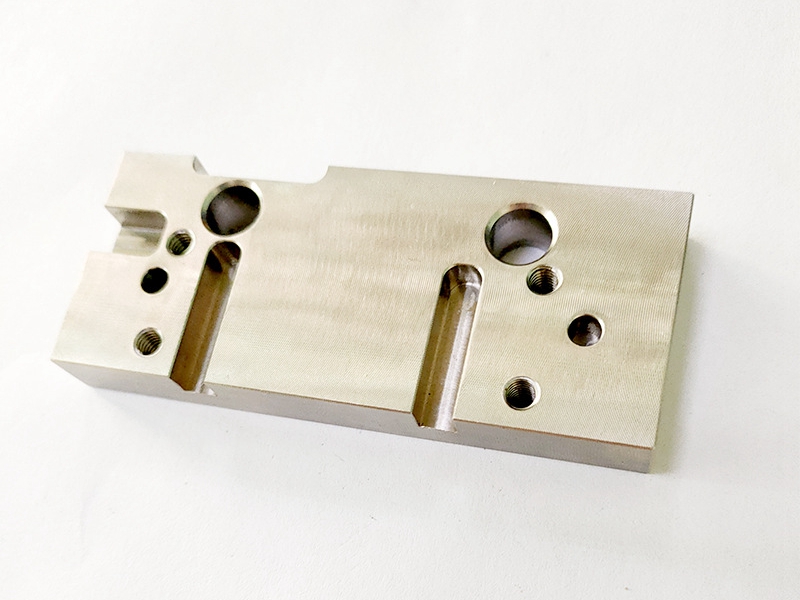

3-Axis CNC Roughing

Initial bulk material removal was performed using 3-axis CNC milling, preserving uniform stock allowances on all heat transfer fins and flat base areas.

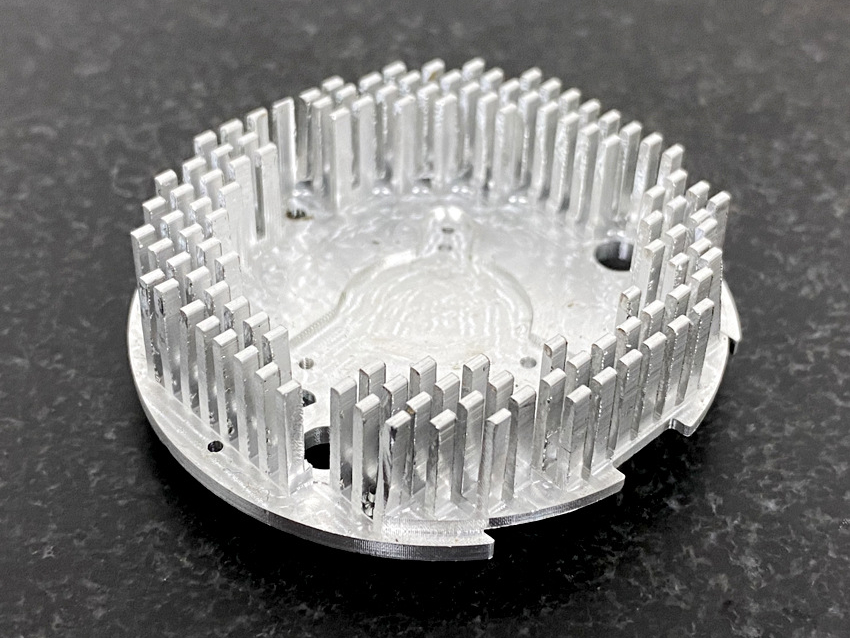

5-Axis CNC Precision Machining

To maintain ultra-flat contact surfaces and sharp fin transitions, 5-axis CNC machining was used for synchronized multi-angle finishing. Flatness across the mounting base was held within ±0.01 mm, and all chamfered edges were machined in a single setup to avoid repositioning errors.

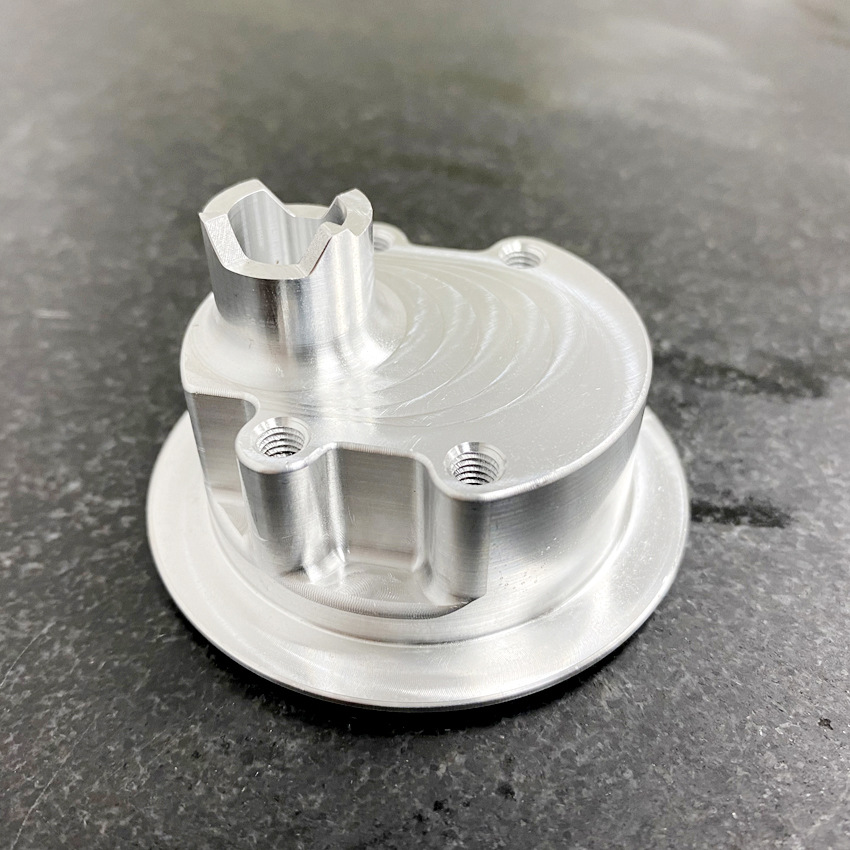

Surface Treatment and Branding

Huawei required durable surface protection and brand compliance for large batch installations. The following surface treatments were applied:

Sandblasting: Uniform matte finish for improved thermal emissivity and powder adhesion

Powder Coating: Applied black thermoset powder layer (60–80 μm) with excellent dielectric and corrosion protection

Laser Marking: Precise product code and Huawei logo application without damaging coating integrity

Quality Assurance and Process Control

CMM Inspection: Full-profile scans verified base planarity, parallelism, and fin spacing

Powder Thickness Testing: Used ASTM D1186 dry film thickness methods to confirm 65 μm average coverage

Logo Precision Audit: Visual and depth verification performed using ISO 20654-compliant inspection

Production Outcome

A batch of 1,500 units was delivered to Huawei’s integration site. All parts passed thermal interface testing and visual grading with >99.8% first-pass yield. Feedback highlighted uniform finish quality, surface resistance to handling abrasion, and consistent dimensional control across the mounting surface.

Why Neway for CNC-Machined Communication Heat Sinks

Aluminum CNC Machining: Ensures complex geometries and flatness tolerance in heat-sensitive assemblies

CNC Milling Service: Ideal for bulk removal in thermal fin structures

One-Stop Manufacturing: Complete workflow from roughing to powder coating and final marking, with tight schedule control

FAQs

What flatness tolerance can be achieved for thermal contact surfaces with 5-axis CNC?

How does powder coating affect thermal conductivity in aluminum heat sinks?

What surface preparation is required before powder coating for telecom-grade components?

Can laser marking penetrate powder without damaging base material?

What dimensional tolerances are critical for heat sink mounting in communication systems?