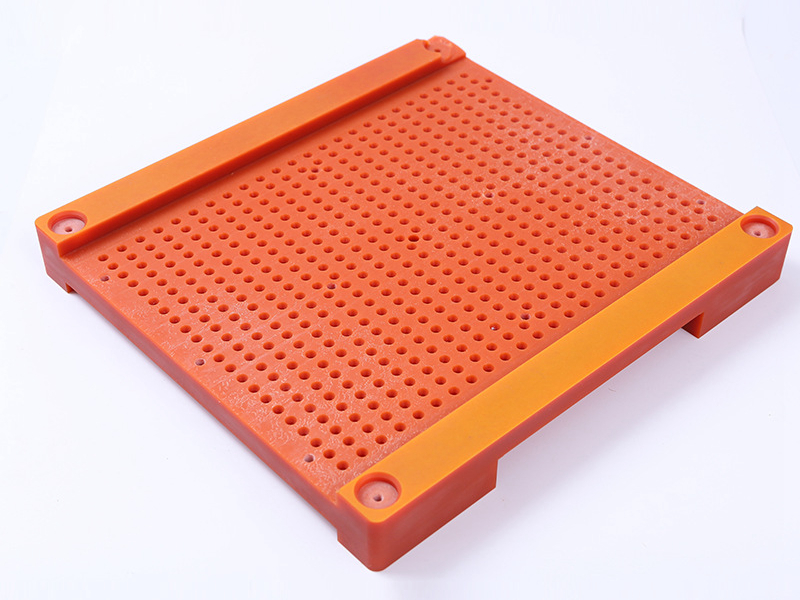

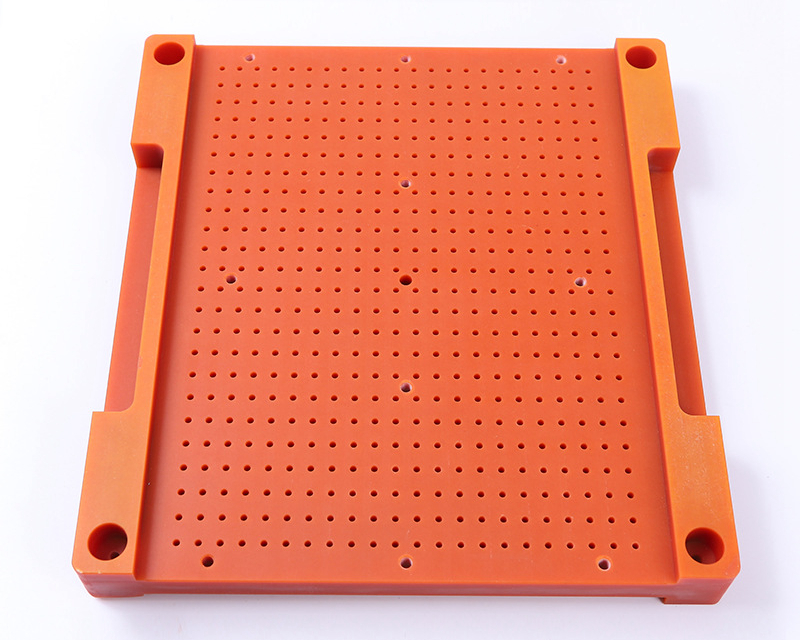

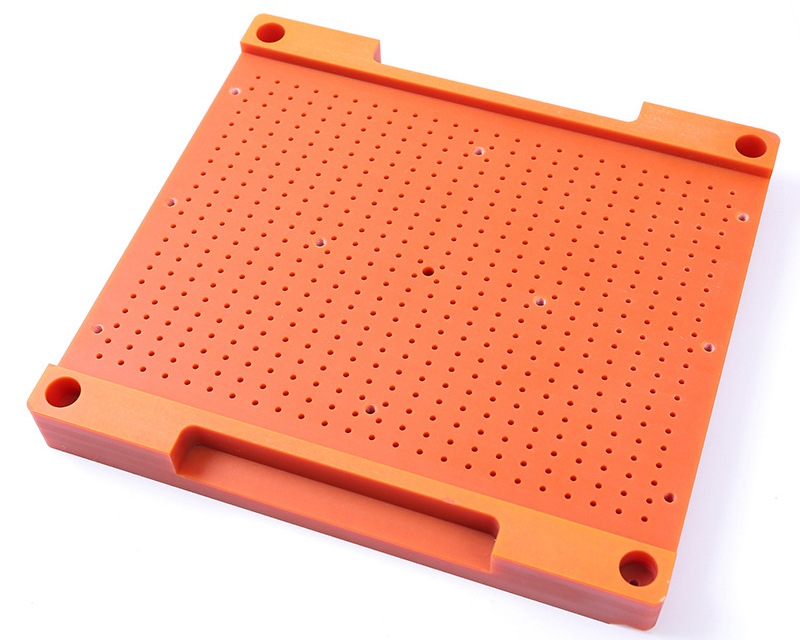

CNC Milling and Drilling Solutions for PEEK Automation Fixtures with As-Machined Surface Finish

CNC Machining of Automation Fixtures: High-Performance PEEK Solutions for Demanding Applications

Automation fixtures require dimensional stability, mechanical strength, and material reliability under repetitive cycles, heat, and chemical exposure. In high-performance automation systems—especially those involving electronics, cleanroom processes, or high-speed handling—PEEK (Polyether Ether Ketone) offers unmatched performance. Neway specializes in CNC milling and CNC drilling of PEEK fixtures for automation applications, delivering components with tight tolerances and stable geometry.

With a clean as-machined surface finish, our PEEK parts are ready for direct use in precision assemblies.

Why PEEK Is Ideal for Automation Fixture Components

Superior Mechanical and Thermal Performance

PEEK offers high tensile strength (~100 MPa), excellent dimensional stability, and a continuous use temperature up to 250°C. It performs reliably in high-speed, high-temperature, and chemically aggressive environments, common in automated semiconductor, medical, and optical production.

Inert and Cleanroom-Compatible

With exceptional chemical resistance and low outgassing, PEEK is well suited for clean automation lines and environments requiring FDA, ISO 14644, or RoHS compliance.

CNC Milling and Drilling Workflow for PEEK Fixtures

CNC Milling for Complex Fixture Geometry

We use optimized carbide tooling, coolant management, and adaptive toolpaths to machine:

Precision slots, pockets, and guides

Fixture bases, locating pins, and support frames

Surface flatness ≤ 0.02 mm for sensor or optical component interfaces

PEEK’s excellent machinability ensures smooth cutting and dimensional accuracy without cracking or delamination.

CNC Drilling for Assembly and Alignment Features

CNC drilling processes are carefully controlled to avoid heat buildup and ensure burr-free results:

Hole tolerance: ±0.02 mm

Clean edges for press-fit or insert-ready holes

Depth consistency for embedded fasteners or precision locating pins

Surface Finish: As-Machined for Functional Precision

An as-machined finish on PEEK provides a natural matte texture with functional surface integrity:

Ra: ~1.6–3.2 µm

No polishing, coating, or post-processing needed

Ideal for direct mechanical integration and handling systems

This finish avoids contamination, retains dimensional accuracy, and supports anti-friction performance in guide rails or sliding mechanisms.

Quality Control and Material Compliance

CMM and optical inspection for profile accuracy and flatness

Surface and hole finish inspection under magnification

Material traceability and batch certification for medical/cleanroom use

Documents: COC, RoHS, REACH, ISO 10993/FDA compliance available upon request

Why Choose Neway for PEEK Automation Fixture Manufacturing

Precision CNC machining of PEEK with high thermal and mechanical control

One-stop production from raw material sourcing to clean-packaging

Expertise in low-volume manufacturing for automation prototyping and system development

Support for regulated industries requiring clean and inert fixture materials

CNC Services for Advanced Polymer Fixture Applications

Neway delivers high-performance polymer fixture components tailored to automation integration. Our services include:

CNC Milling and Drilling: For geometrically complex and high-precision fixture designs

PEEK Material Machining: Heat-resistant and chemically inert parts for automated environments

As-Machined Surface Finish: Clean, functional surfaces for direct-use integration

We help automation system manufacturers ensure part longevity, operational precision, and clean compatibility with engineered PEEK components.

FAQs

What tolerances can you achieve for CNC-milled PEEK fixture components?

Is as-machined PEEK suitable for cleanroom and medical applications?

Can Neway handle both flat and 3D contour geometries in PEEK?

What are the typical Ra values for as-machined PEEK surfaces?

Do you provide documentation for FDA- or ISO-compliant material batches?