Quel est le délai typique d’un projet de perçage profond, de la demande à la livraison ?

Le délai de livraison des projets de forage de trous profonds varie considérablement en fonction de plusieurs facteurs, mais se situe généralement entre 2 et 8 semaines pour les projets standards. Les composants complexes présentant des tolérances serrées, des matériaux exotiques ou des opérations secondaires supplémentaires prolongent naturellement ce délai. Chez Neway, nous avons développé un processus rationalisé qui maintient la qualité tout en optimisant les délais de livraison afin de répondre aux exigences de production de nos clients dans divers secteurs.

Facteurs clés influençant le calendrier du projet

Plusieurs éléments critiques influencent directement la durée totale, de la demande de devis initiale à la livraison finale, chacun nécessitant une attention particulière lors de la planification du projet.

Complexité et spécifications des composants

Les caractéristiques physiques de votre composant affectent considérablement le temps de traitement :

Profondeur et diamètre du trou : Les composants nécessitant des trous avec des rapports de profondeur/diamètre extrêmes (supérieurs à 30:1) nécessitent souvent des outils spécialisés et des vitesses d’avance plus lentes, ce qui prolonge le temps d’usinage. Nos capacités de Service de perçage CNC incluent des équipements spécialisés pour ces applications exigeantes.

Usinabilité des matériaux : Les matériaux standards comme l’aluminium 6061 sont usinés plus rapidement que les alliages exotiques tels que l’Inconel 718 ou le Ti-6Al-4V (TC4), qui nécessitent des paramètres réduits et des outils spécialisés.

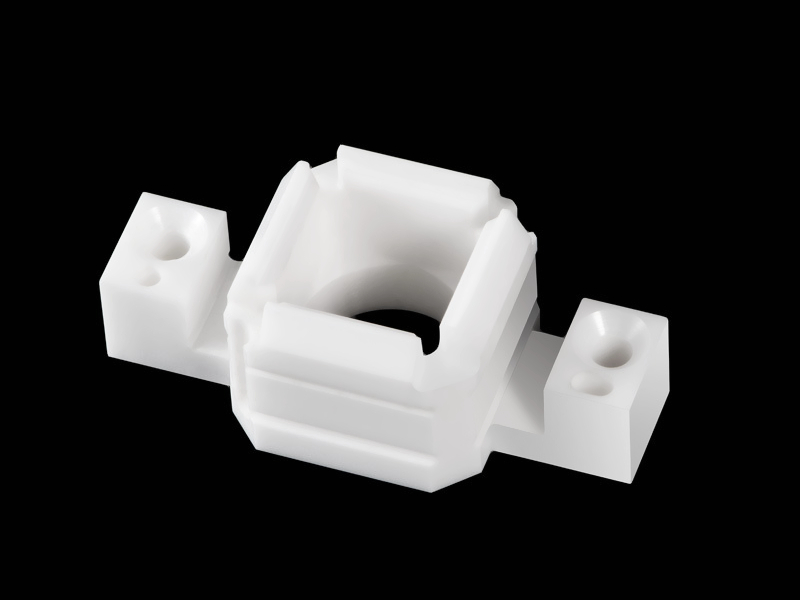

Exigences de tolérance : Le maintien de tolérances serrées (IT7-IT9) exige un temps supplémentaire pour la configuration minutieuse, la vérification en cours de processus et éventuellement des opérations secondaires telles que le rodage.

Quantité et approche de fabrication

Le volume de production influence considérablement l’approche de fabrication choisie et le calendrier associé :

Quantités de prototypes (1-10 pièces) : En général 1-3 semaines après confirmation de la commande, en mettant l’accent sur un délai rapide grâce à nos capacités de Prototypage en usinage CNC.

Production à faible volume (10-500 pièces) : Généralement 3-5 semaines, permettant une optimisation des outils et des processus via notre Service de fabrication en petite série.

Production à grand volume (500+ pièces) : Typiquement 5-8 semaines ou plus, impliquant la conception d’outillages dédiés, la validation des processus et la planification de la production dans le cadre de notre Service de production de masse.

Répartition du calendrier étape par étape

Comprendre la durée typique de chaque phase du projet aide à établir des attentes réalistes en matière de livraison.

Devis et examen technique (1-3 jours ouvrables)

Notre réponse à votre demande de devis (RFQ) est généralement fournie dans un délai de 1 à 3 jours ouvrables, selon la complexité du projet. Cette phase comprend :

Analyse de conception pour la fabricabilité (DFM)

Planification du processus et évaluation de l’outillage

Vérification de la disponibilité des matériaux

Préparation du devis formel

Planification de la pré-production (3-5 jours ouvrables)

Une fois la commande confirmée, nous lançons des activités complètes de pré-production :

Préparation de l’outillage et conception des fixations : Des outillages ou dispositifs personnalisés peuvent être nécessaires pour les composants complexes, notamment dans les applications de Service d’usinage de précision.

Développement et vérification des programmes : Les programmes CNC sont créés et simulés pour garantir des trajectoires d’outils optimales et éviter les collisions.

Approvisionnement en matériaux : Les matériaux standards sont généralement en stock, tandis que les alliages exotiques peuvent nécessiter un délai supplémentaire.

Fabrication et assurance qualité (1-4 semaines)

La durée de la phase de production principale varie selon les spécifications du composant :

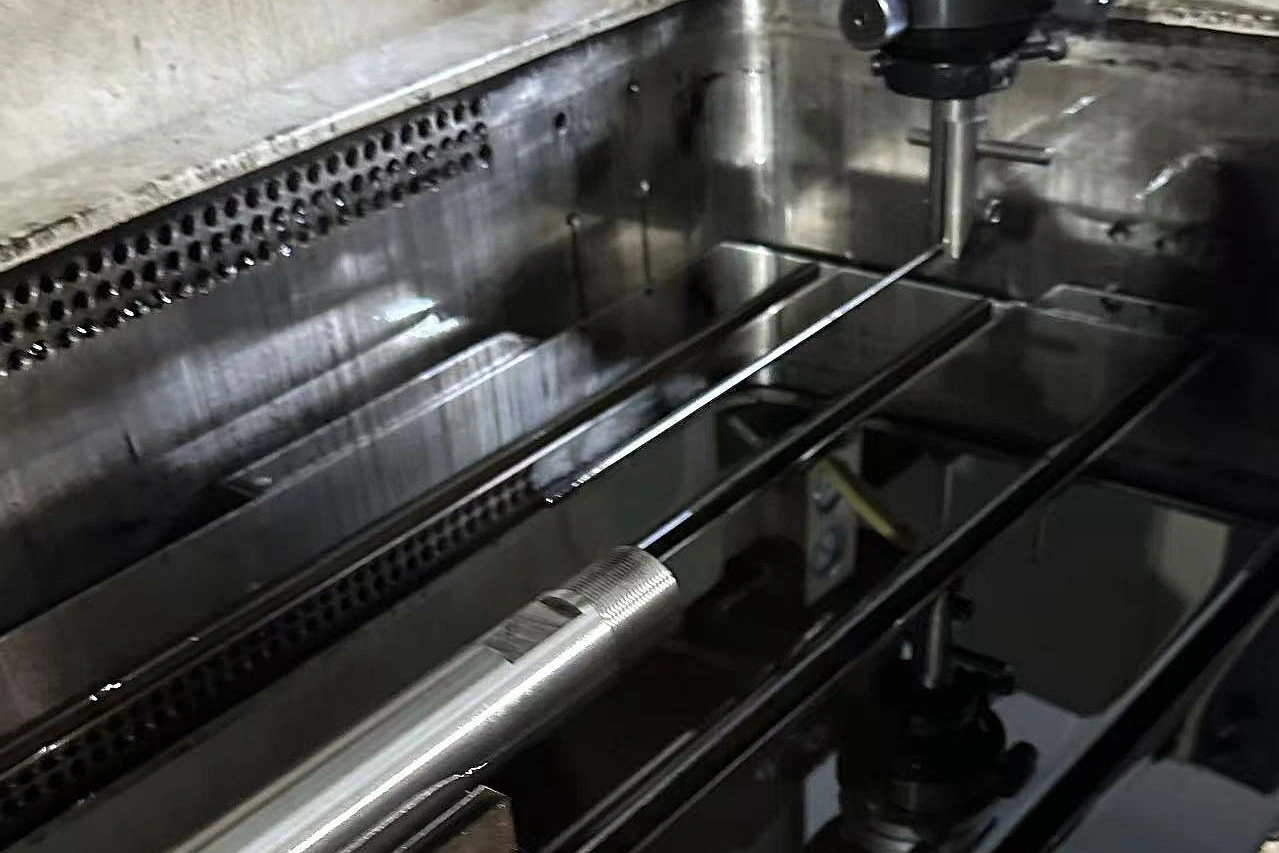

Opérations d’usinage principales : Y compris le Service de fraisage CNC et le Service de tournage CNC pour établir la géométrie de base de la pièce avant le forage de trous profonds.

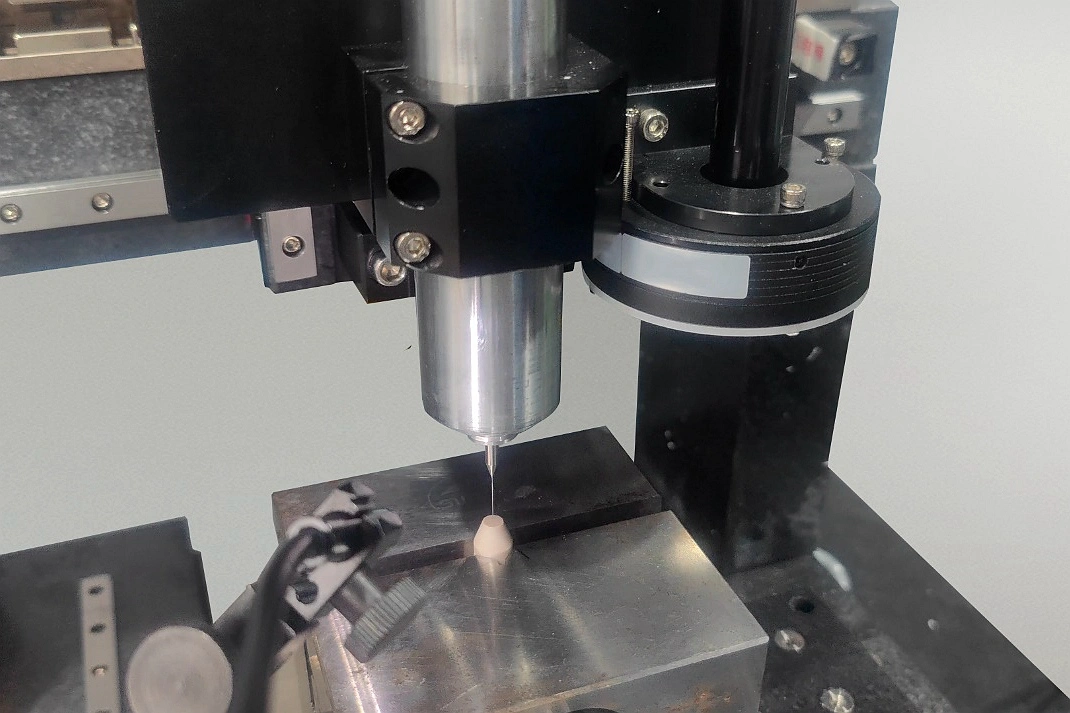

Opérations de forage de trous profonds : La phase la plus chronophage, notamment pour les trous profonds et de petit diamètre nécessitant un contrôle minutieux des paramètres.

Opérations secondaires : Des caractéristiques supplémentaires peuvent nécessiter le Service d’alésage CNC ou le Service de rectification CNC pour obtenir des tolérances précises.

Application du traitement de surface : Les procédés tels que l’électropolissage pour les pièces de précision ou la passivation pour l’acier inoxydable ajoutent 2-5 jours selon le traitement spécifique.

Inspection complète : Métrologie avancée pour la vérification des trous profonds, y compris la mesure du diamètre interne, l’évaluation de la rectitude et la vérification de l’état de surface.

Traitement final et livraison (2-5 jours ouvrables)

La phase finale comprend :

Documentation finale de qualité et certification

Préparation de l’emballage et de l’expédition

Coordination logistique avec diverses options de transport

Considérations sectorielles spécifiques sur les délais

Différents secteurs d’application ont des exigences uniques qui influencent la durée du projet :

Composants aéronautiques et de défense

Les projets pour l’aéronautique et l’aviation nécessitent généralement une documentation supplémentaire, la traçabilité des matériaux et une vérification rigoureuse de la qualité, ce qui peut ajouter 1-2 semaines au délai standard.

Fabrication de dispositifs médicaux

Les composants pour dispositifs médicaux nécessitent souvent des procédés validés, des certifications de biocompatibilité et des traitements de surface spécialisés tels que l’électropolissage, prolongeant les délais de 1 à 3 semaines.

Applications automobiles et industrielles

Les composants pour l’automobile et les équipements industriels suivent généralement des délais standards, avec une accélération possible pour la production à grand volume via des processus établis.

Stratégies d’optimisation des délais

Nous proposons plusieurs approches pour réduire les délais lorsque cela est nécessaire :

Traitement accéléré : Planification prioritaire disponible pour les projets urgents, pouvant réduire les délais de 30 à 50 % pour les composants standards.

Collaboration précoce en conception : Impliquer notre équipe d’ingénierie dès la phase de conception via notre Service tout-en-un permet d’identifier rapidement les défis de fabrication potentiels et d’éviter les retards pendant la production.

Sélection de matériaux standards : Choisir des matériaux facilement disponibles comme l’acier inoxydable SUS303 ou l’aluminium 6061 plutôt que des alliages exotiques peut réduire le temps d’approvisionnement.

Livraisons échelonnées : Pour les grandes quantités, nous pouvons organiser des livraisons échelonnées afin de soutenir votre calendrier de production tout en maintenant les normes de qualité.

En comprenant ces facteurs et en maintenant une communication ouverte tout au long du processus, nous assurons des délais de projet prévisibles qui s’alignent sur vos exigences opérationnelles tout en offrant la précision et la qualité attendues de l’expertise de Neway en forage de trous profonds.