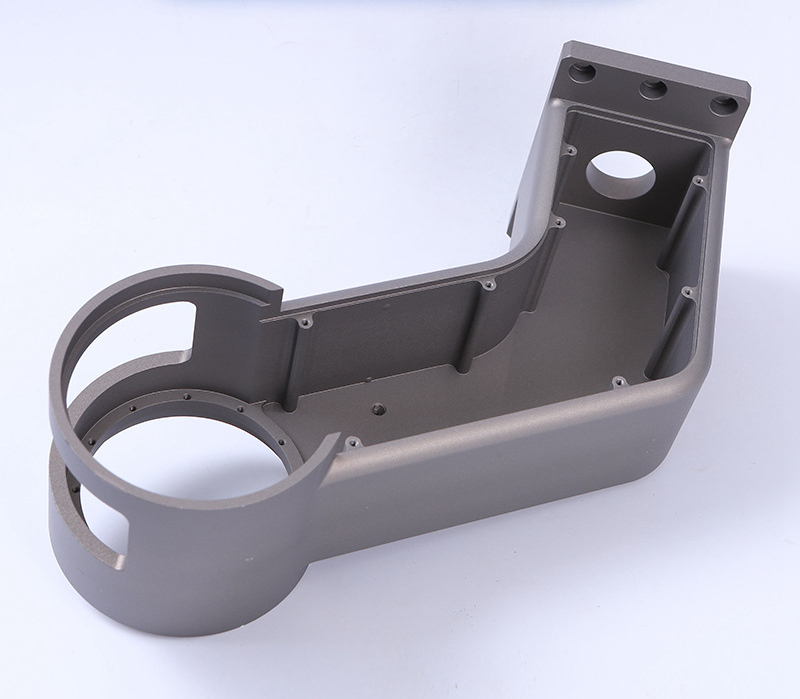

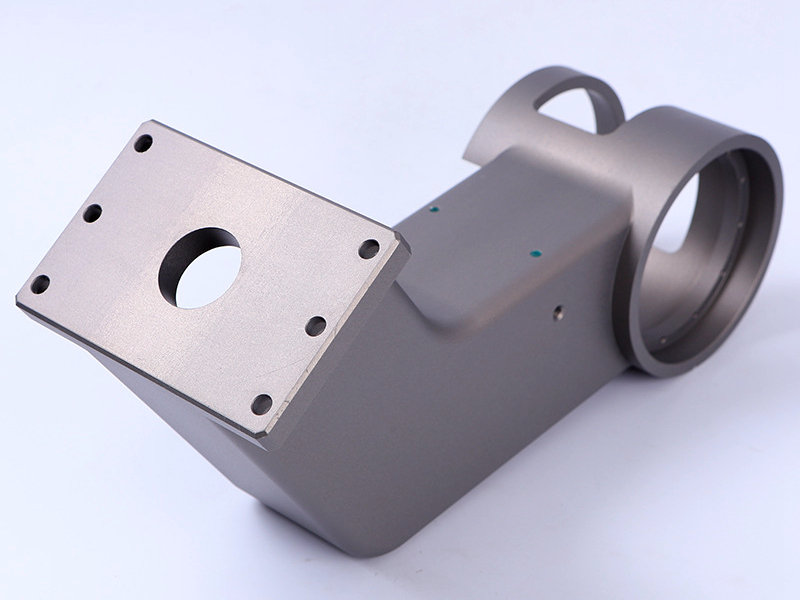

Multi-Axis CNC Machining and Anodized Finishing for Aluminum 6061 Robotic Joints

CNC Machining of Robotic Joints: Lightweight Strength and Motion Accuracy for Robotics

Robotic joints require precise mechanical articulation, lightweight construction, and consistent geometric accuracy to support real-time motion control in automation, service, and industrial robotics. At Neway, we specialize in multi-axis CNC machining and precision aluminum machining of Aluminum 6061 to produce high-strength, lightweight robotic components with complex features and tight tolerances.

To meet both functional and aesthetic requirements, we apply sandblasting and anodizing surface treatments, ensuring excellent surface quality, corrosion protection, and color consistency for joint modules.

Why Aluminum 6061 Is Ideal for Robotic Joint Components

High Strength-to-Weight Ratio

Aluminum 6061 offers excellent tensile strength (~310 MPa), low density (2.7 g/cm³), and rigidity, making it a top choice for articulated robotic structures where inertia reduction and response precision are critical.

Excellent Machinability and Surface Compatibility

This alloy performs well in high-speed CNC operations and supports tight dimensional control, making it suitable for rotary housings, bearing mounts, and joint brackets. It also responds well to surface treatments like anodizing and media blasting.

Multi-Axis Precision Machining for Robotic Joints

Multi-Axis Machining for Complex Features

We use 4- and 5-axis machining centers to produce robotic joints with integrated channels, undercuts, and mating surfaces in a single clamping. Key capabilities include:

Tolerances: ±0.01 mm on critical fit zones

Angular flatness for sensor or motor mounting planes

Internal pockets and gear integration zones

Precision Machining for Dynamic Interface Surfaces

Machining accuracy ensures the joints operate with minimal backlash and maximum positional repeatability. Features include:

Precision bores for bearings and dowel fits

Ground interfaces for high-load contacts

Chamfered transitions and blended curves for aesthetic and ergonomic optimization

Surface Treatment: Sandblasting and Anodizing

Sandblasting for Texture Uniformity

Sandblasting is used before anodizing to create a matte, consistent finish that hides machining marks and prepares the surface for uniform oxide layer formation. It improves part aesthetics and adhesion of the anodized layer.

Anodizing for Corrosion Resistance and Color Coding

We apply anodizing to enhance durability and visual identity:

Type II (decorative) or Type III (hardcoat) anodizing

Colors: black, silver, red, blue (customizable)

Thickness: 10–25 µm depending on function

Electrical insulation and scratch resistance

Quality Control and Engineering Support

CMM inspection of complex geometries and assembly interfaces

Flatness, concentricity, and bore alignment verification

Anodizing thickness and adhesion testing

Certifications: COC, RoHS, REACH, full material traceability

Why Choose Neway for Robotic Joint Component Manufacturing

Expertise in Aluminum 6061 CNC machining with multi-axis process optimization

Integrated sandblasting and anodizing finishing for ready-to-assemble parts

Low-volume to full-scale production with full QA documentation

One-stop CNC manufacturing including design support, machining, and finishing

CNC Services for Robotic Joint Assembly Projects

Neway provides complete CNC manufacturing solutions for robotic joint modules, including:

Multi-Axis Machining: Complex undercut, angular, and curved features in one setup

Aluminum 6061 Precision Machining: Lightweight, dimensionally stable structural parts

Sandblasting and Anodizing Services: Durable and aesthetic surface finish for exposed assemblies

We support robotics OEMs with consistent delivery of precision joint components engineered for motion accuracy and assembly fit.

FAQs

What tolerance levels can be achieved for multi-axis machined robotic joints?

How does anodizing affect the fit and assembly of robotic joint components?

Can Neway support both Type II and Type III anodizing finishes?

What material certificates and QA reports are provided with robotic parts?

Do you support low-volume production for prototype robotic joints?