Cómo entender las cotizaciones CNC: los 10 factores que afectan el costo de las piezas

Introducción

Las cotizaciones de mecanizado CNC están determinadas por una interacción compleja entre parámetros de diseño, características del material, selección de procesos de fabricación y cantidades requeridas. Para los ingenieros de compras y los desarrolladores de producto, comprender la estructura de costes detrás de los servicios de mecanizado CNC es fundamental para optimizar las estrategias de diseño orientado al coste (design-to-cost) y garantizar la viabilidad del proyecto.

Este artículo presenta los 10 principales factores que impulsan el precio y que influyen en las cotizaciones de mecanizado CNC, basados en prácticas estándar del sector y datos de costes empíricos.

1. Tipo y Grado de Material

La selección de material influye directamente tanto en el coste base como en la maquinabilidad. Los materiales estándar, como el aluminio 6061, ofrecen una excelente maquinabilidad y una buena relación coste-prestaciones, mientras que aleaciones avanzadas como Inconel 718 o titanio Ti-6Al-4V son significativamente más caras debido al mayor coste del material y a una eficiencia de mecanizado reducida.

Material | Índice Relativo de Coste de Mecanizado | Notas |

|---|---|---|

Aluminio 6061 | 1,0 | Alta maquinabilidad |

Acero inoxidable 304 | 1,8 | Requiere avances (feed) más lentos |

Inconel 718 | 3,2 | Exige herramientas de alto rendimiento |

Titanio TC4 | 2,9 | Genera un desgaste rápido de herramienta |

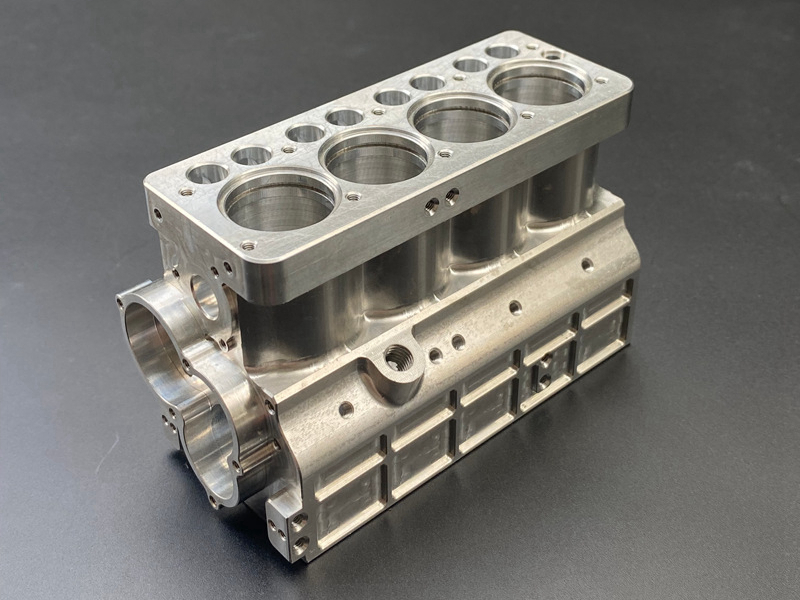

2. Geometría y Complejidad de la Pieza

Características de diseño como cavidades profundas, paredes delgadas y contornos intrincados incrementan la complejidad del mecanizado. Los componentes que requieren mecanizado multieje implican tiempos más largos de preparación (setup) y programación de trayectorias CAM, lo que se traduce en mayores costes de mano de obra y uso de máquina. La simplificación del diseño puede reducir directamente los valores de la cotización.

3. Tolerancia Dimensional

Las tolerancias estrictas (±0,01 mm o inferiores) requieren compensaciones adicionales de herramienta, velocidades de corte más bajas e inspecciones más exigentes. Las características de alta precisión, como alojamientos o ajustes de precisión, suelen necesitar operaciones secundarias como el mandrinado CNC, lo que aumenta el tiempo de ciclo y el precio unitario.

4. Requisitos de Acabado Superficial

Los acabados especificados influyen de forma significativa en el coste de post-procesado. Las superficies estándar “as-machined” añaden un coste mínimo, mientras que el anodizado, el pintado o los recubrimientos térmicos pueden incrementar el coste de la pieza entre un 15 % y un 60 %, dependiendo de la aplicación y del tamaño del lote.

5. Cantidad y Tamaño de Lote

El coste unitario disminuye a medida que aumenta el volumen, gracias a la amortización del tiempo de preparación y de herramienta. Para tiradas pequeñas, el mecanizado CNC de bajo volumen permite optimizar la flexibilidad de fabricación; sin embargo, se traduce en precios por pieza más altos debido a los costes fijos de puesta en marcha.

6. Requisitos de Plazo de Entrega

Los plazos de entrega acelerados pueden afectar a la planificación de producción y requerir horas extra, compras urgentes o la priorización de pedidos críticos. Las cotizaciones con plazos cortos suelen incluir un recargo que puede oscilar entre el 10 % y el 30 %, según la carga de trabajo y el nivel de utilización de la capacidad.

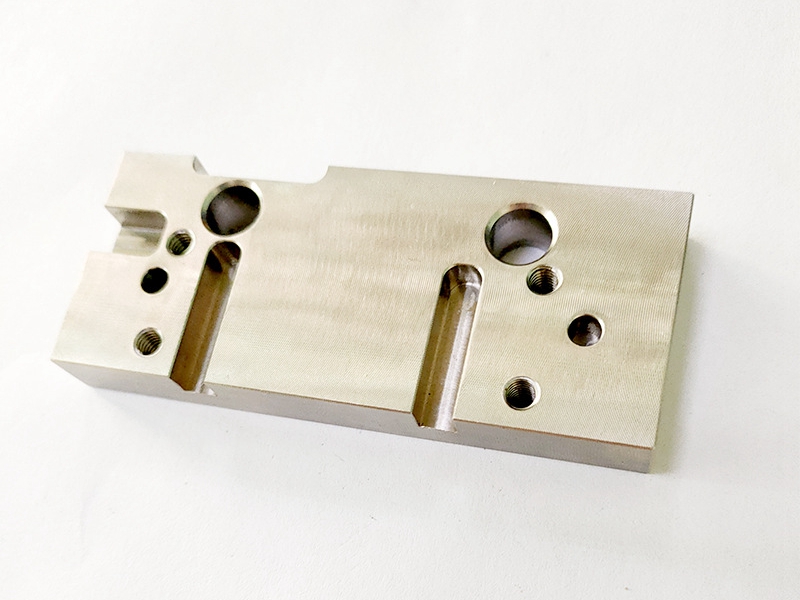

7. Utillaje y Fijación

Las geometrías irregulares requieren útiles específicos o mordazas blandas, lo que introduce costes de ingeniería no recurrentes (NRE). Las soluciones de fijación reutilizables pueden reducir el coste en pedidos repetitivos, pero para un mecanizado inicial, el tiempo de preparación y diseño de utillaje es un componente de coste importante.

8. Selección de Procesos de Mecanizado

Los procesos necesarios —como fresado CNC, torneado, EDM o rectificado CNC— determinan el número total de horas de mecanizado y el consumo de herramientas. Los componentes que requieren múltiples operaciones secundarias o utillaje especializado, de forma inherente, generan costes más elevados.

9. Complejidad de Programación CAD/CAM

Los sistemas de cotización tienen en cuenta la complejidad CAM basándose en la geometría del modelo y en la claridad del GD&T. Las piezas 3D muy contorneadas o los conjuntos con tolerancias ambiguas requieren tiempos de programación más largos y pueden originar un incremento en la cotización para cubrir el esfuerzo adicional de programación.

10. Aseguramiento de la Calidad y Documentación

En sectores como el aeroespacial o el médico, las piezas suelen requerir informes de CMM, certificación de material o conformidad con normas documentales específicas (por ejemplo, PPAP, ISO). Estos requisitos de inspección añaden costes de mano de obra medibles y pueden ampliar el plazo de elaboración de la cotización.

Conclusión

Una cotización de mecanizado CNC no es un simple precio: refleja la suma de decisiones estratégicas en material, diseño e ingeniería de procesos. Al comprender los factores principales que afectan al coste, los compradores pueden optimizar el diseño para la fabricación (DFM) y negociar de forma más eficaz con fabricantes CNC de confianza. Para lograr una producción rentable, la colaboración temprana con el proveedor de mecanizado es esencial.

FAQs

¿Cómo puedo reducir los costes de mecanizado CNC sin comprometer la función?

¿Cuál es la diferencia de coste entre piezas CNC en aluminio y en titanio?

¿Cambios pequeños en tolerancias afectan de forma significativa el precio de la cotización?

¿El tratamiento superficial siempre está incluido en las cotizaciones de mecanizado CNC?

¿Cómo influye la complejidad de la pieza en el plazo de mecanizado y el coste?