Key Factors to Consider in Titanium CNC Machining Projects

Introduction: Multi-Dimensional Considerations for Successful Titanium CNC Projects

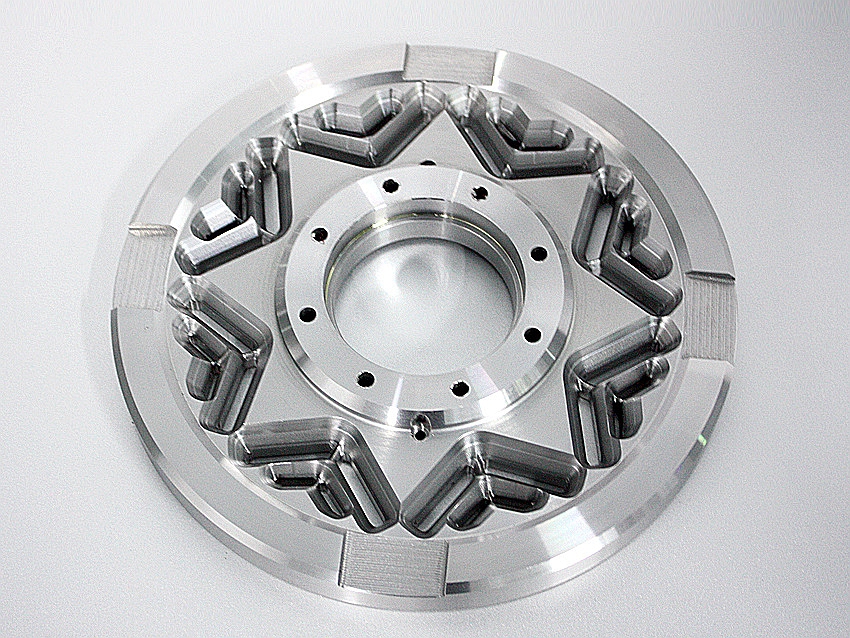

Across the many titanium CNC machining projects we handle at Neway, one pattern is crystal clear: project success is never just about having good machines or hard tools. Titanium is a demanding, high-value, high-performance material. To machine it right, you need systematic thinking from day zero — material selection, part design, machining strategy, equipment capability, quality control, risk management, and supply chain all have to work together.

Every titanium component is effectively a custom engineering challenge. From alloy grade to blank form, from toolpath to inspection plan, each decision affects quality, cost, and lead time. In this article, drawing on Neway’s engineering experience, we break down the key success factors you should consider when planning and executing titanium CNC machining projects.

Technical Factor I: Deep Understanding of Material Properties & Grade Selection

Comparing Mechanical & Physical Properties Across Titanium Grades

The choice of titanium grade directly determines technical feasibility, durability, and machining difficulty. Ti-6Al-4V (TC4) is the most widely used α-β titanium alloy, offering an excellent balance of strength, weight, corrosion resistance, and machinability, making it ideal for most structural parts. Ti-6Al-4V ELI (Grade 23) features a lower interstitial content and higher toughness, making it a preferred material for medical implants and critical load-bearing components.

For higher strength requirements, Ti-10V-2Fe-3Al (Grade 19) and other β alloys offer excellent mechanical performance, but they are significantly more difficult to machine. Ti-3Al-2.5V (Grade 12) combines good strength with outstanding cold formability, making it a strong candidate for tubing and hydraulic system components.

Influence of Supply Form & Material Condition

The form and condition of the material (bar, forging, near-net preform, plate, or tube) directly influence machining strategy, utilization, and cost. Forgings typically offer better mechanical properties and closer-to-final geometry, reducing machining volume but increasing initial cost. Bars and plates are suitable for simpler geometries or prototypes. Early in the project, we evaluate structure, buy-to-fly ratio, and mechanical requirements to choose the most economical and reliable material route.

Technical Factor II: Co-Design of Part Geometry & Manufacturability

Evaluating Design Features that Drive Machining Difficulty

In our precision machining services, we emphasize early Design for Manufacturing (DFM) reviews. Features such as ultra-thin walls, deep pockets, sharp internal corners, narrow slots, and small-diameter deep holes significantly increase risk of chatter, deformation, tool breakage, and scrap. Through early collaboration, we help customers adjust radii, wall thickness, transitions, and access paths without compromising function, but greatly improving machinability and yield.

Rational Definition of Tolerances & Surface Finish

Tight tolerances and ultra-fine surface finishes are expensive — especially on titanium. We recommend a tiered tolerance strategy: apply strict tolerances only to critical functional surfaces (mating faces, sealing areas, load paths, interfaces), while relaxing requirements for non-critical zones. In our multi-axis machining operations, optimized toolpaths and stable setups allow us to achieve demanding GD&T and surface finish targets on complex 3D geometries, but always with a cost-performance balance in mind.

Technical Factor III: Process Strategy & Tooling Integration

Differentiated Machining Strategies

We tailor roughing, semi-finishing, and finishing into distinct stages. Roughing: higher feed, moderate speed, controlled depth of cut to maximize removal while managing heat. Finishing: conservative parameters to ensure surface integrity, dimensional accuracy, and minimal residual stress. For difficult alloys such as Beta C, we use more stable, conservative parameter windows backed by our in-house process database.

Specialized Tooling & Cooling Strategies

Tooling is decisive. We use titanium-optimized carbide tools, sharp geometries, variable-helix end mills, and high-performance coatings, combined with high-pressure through-tool coolant. In our CNC milling services, each operation (slotting, contouring, pocketing, drilling, reaming) is matched with specific tool geometry, cooling, and toolpath strategies to stabilize cutting forces and suppress heat, wear, and chatter.

Equipment Factor: Machine Capability & Precision Assurance

Evaluating Machine Tool Requirements

Titanium machining demands high-rigidity structures, powerful low-speed torque, precise spindle control, and robust thermal stability. We assess: static/dynamic stiffness, spindle torque curve, axis accuracy & repeatability, and integration of high-pressure coolant systems. Only machines meeting these criteria are allocated to critical titanium projects.

Automation for Consistency & Throughput

For volume programs, we configure automation such as robotic loading, pallet pools, tool monitoring, and in-process measurement. In our CNC turning services, automation enables stable 24/7 production, improving consistency while lowering per-part cost.

Quality Factor: Building an End-to-End Quality Control System

In-Process Monitoring & Control

We implement full-process quality control from incoming material to final inspection. In-process probing, tool wear monitoring, and SPC help detect deviations early. For CNC drilling, we monitor hole position, diameter, and surface condition to ensure consistent quality even in deep or small-diameter holes.

Execution of Final Inspection Standards

The final inspection encompasses dimensional accuracy, GD&T, surface roughness, and visual appearance. We utilize CMMs, profilometers, contour tracers, and, where necessary, non-destructive testing methods. In CNC grinding of titanium, we verify both geometry and surface integrity to ensure compliance with customer and industry standards.

Management Factor I: Project Planning & Risk Control

Manufacturing Feasibility Analysis

Before launch, we conduct detailed feasibility assessments, including material routing, fixturing concepts, deformation risks, tool access, cycle time, and potential failure modes. Using prototyping services, we validate process concepts and stabilize parameters before scaling to production.

Project Timeline Management

We define clear milestones: DFM review, prototype completion, PPAP/FAI, ramp-up, and mass production. Through CNC prototyping, we compress development cycles and provide customers with rapid feedback, while strict progress tracking ensures delivery commitments are met.

Management Factor II: Cost Optimization & Supply Chain Control

Cost Optimization Strategies

Titanium is expensive — both in terms of material and machining. We reduce costs through optimized buy-to-fly ratios, robust tool life management, standardized process modules, and efficient setups. In low-volume manufacturing, smart fixturing and shared platforms cut NRE and setup costs while maintaining quality.

Supply Chain Management

We maintain a qualified supplier network for titanium materials, heat treatment, and special processes. Through rigorous audits and continuous monitoring, we ensure material traceability, certification integrity, and stable lead times throughout the entire supply chain.

Industry-Specific Requirements: Meeting Application-Level Standards

Aerospace Requirements

For the aerospace industry, we adhere to stringent standards that encompass material qualification, process control, FAI, documentation, and full traceability. From the billet certificate to the final inspection record, every step is meticulously documented to support airworthiness and long-term reliability.

Medical Device Requirements

For medical devices, we emphasize biocompatibility, contamination control, burr-free edges, and surface integrity. Controlled environments, validated processes, and appropriate post-processing (e.g., passivation, polishing) ensure compliance with medical standards.

The Critical Role of Post-Processing & Surface Engineering

Heat Treatment Control

Through heat treatment services, we refine microstructure, relieve residual stresses, and stabilize dimensions. Different titanium alloys and applications require customized heat treatment cycles; we design routes to match the required strength, toughness, and fatigue performance.

Surface Treatment Technologies

Surface engineering tailors titanium parts for their real-world environment. Passivation enhances corrosion resistance, titanium anodizing improves wear resistance and aesthetics, and mechanical & chemical polishing refine surface quality and reduce stress concentrators. We select and validate processes based on each component’s load, medium, and regulatory requirements.

Selecting the Right Titanium CNC Manufacturing Partner

Choosing a titanium machining partner means looking beyond machine lists. You should evaluate: engineering competence, DFM & process development capability, quality systems & certifications, application experience, traceability, and responsiveness.

At Neway, our one-stop service integrates design optimization, prototyping, validation, and mass production. With experience spanning automotive, robotics, industrial equipment, and aerospace, as well as capabilities such as EDM and mass production, we help customers transform demanding titanium concepts into repeatable, certifiable components.

FAQ

How to evaluate a supplier’s real titanium CNC machining capability?

What is the usual timeline from design review to final titanium delivery?

How do small-batch and large-batch titanium production differ in approach?

How to solve common titanium issues like chatter, burrs, or deformation?

How to balance titanium’s higher cost with strict performance and quality needs?