CNC Machining vs 3D Printing: Choosing the Right Process for Prototypes and Production

Introduction

Selecting the right manufacturing process—CNC machining or 3D printing—is critical to the success of modern product development. Each technology offers distinct advantages, depending on factors such as material requirements, geometry, surface finish, lead time, and production volume.

At Neway Machining, both CNC and 3D printing services are integrated into a unified workflow, spanning from prototyping to production, allowing customers to select the optimal method based on their project goals. In this guide, we explore how to select between these two powerful technologies for both prototyping and production.

Understanding the Core Differences Between CNC and 3D Printing

Process Fundamentals

CNC machining is a subtractive process. It removes material from a solid block using precision-controlled cutting tools. It is well-suited for producing high-strength, dimensionally accurate parts from metals and engineering plastics.

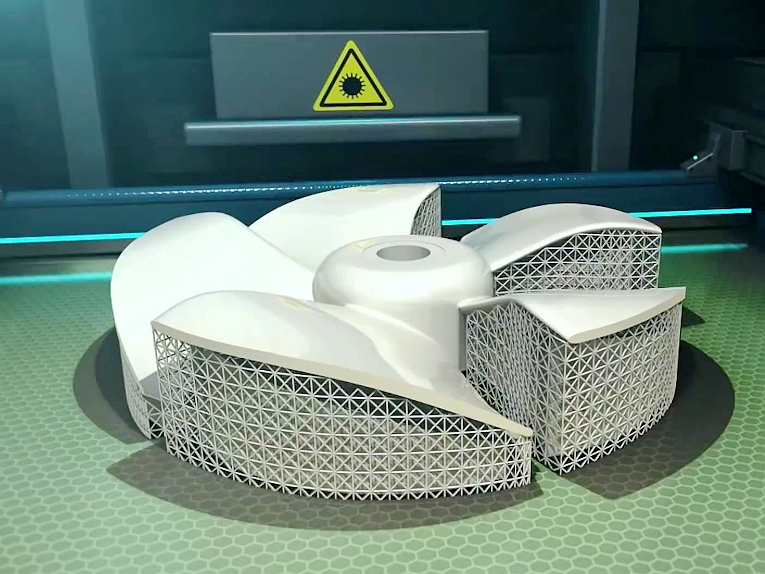

3D printing, or additive manufacturing, builds parts layer by layer from digital models. It excels at producing complex geometries that may be difficult or impossible to machine. It is commonly used for rapid prototyping and short-run production, especially in polymers and some advanced metals.

Materials Capability

CNC machining supports an extensive range of materials, including:

Engineering plastics such as PEEK and Delrin

3D printing materials vary by process (SLS, SLA, DMLS, FDM). At Neway, 3D printing supports materials such as:

Nylon (PA12)

Resin-based materials for SLA

Metal powders such as Inconel and stainless steel

High-performance polymers like ULTEM and PEEK

Geometric Flexibility

3D printing provides unmatched geometric flexibility. It allows for:

Complex internal channels

Organic shapes

Lightweight lattice structures

Single-piece assemblies that would require multiple CNC setups

CNC machining, in contrast, delivers superior dimensional accuracy and surface finish, but is constrained by tool reach and workholding. It excels at:

Tight-tolerance features

Smooth flat surfaces

Cylindrical precision components

Parts requiring high mechanical strength

Cost, Lead Time, and Production Considerations

Cost Drivers in CNC Machining

CNC machining costs are driven by several factors:

Material selection: Raw materials such as Inconel 718 or titanium alloys are more expensive than aluminum or plastics.

Machining time: Complex parts with tight tolerances or intricate 3D contours increase machine cycle time.

Tooling and setup: Multi-axis setups or custom fixturing for complex parts (such as copper C175) increase initial costs.

For small batches, setup time becomes a larger portion of unit cost. Once setup is complete, per-part costs decrease as production volume increases, making CNC machining cost-efficient for low to medium production runs.

Cost Structure in 3D Printing

3D printing cost is largely based on:

Material volume: Parts with large volumes or dense infill require more material.

Build time: Taller parts or high-resolution prints increase build duration.

Post-processing Steps, such as UV coating, support removal, and finishing, add labor costs.

Unlike CNC machining, 3D printing does not require tooling or fixturing, making it highly cost-effective for one-off and small-batch production. Unit costs remain relatively flat regardless of quantity, which is advantageous during prototype phases.

Lead Time Comparison

3D printing typically offers faster lead times, particularly for design validation. A simple plastic prototype can often be printed within 1–3 days, enabling rapid iteration.

CNC machining lead time depends on material availability, complexity, and shop scheduling. For example:

A simple aluminum 7075 prototype may require 5–7 days.

A complex stainless steel SUS630 aerospace part could take 2–3 weeks, including CMM inspection and documentation.

For projects with tight timelines, combining 3D printing for early iterations and CNC machining for final validation is a highly effective strategy.

Production Scalability

When transitioning from prototype to production, scalability is crucial.

CNC machining scales well for low-to-medium volume (10–1,000 parts). The process is stable and repeatable, with excellent dimensional control and surface finish. For example, medical titanium implants require consistent quality across batches.

3D printing is ideal for bridge production—short runs of tens to hundreds of parts before tooling investment is justified. It is also used for spare parts, mass customization, or geometries unsuited to traditional machining.

Hybrid Manufacturing Approach

Many modern projects benefit from a hybrid approach:

3D printing for design flexibility

CNC machining for final precision and structural components

For example, robotics housings may combine 3D-printed complex shells with CNC-machined internal brackets made from carbon steel 4340.

This allows engineers to optimize performance, cost, and lead time throughout the product life cycle.

Dimensional Accuracy and Tolerances

CNC machining delivers superior dimensional accuracy. Standard machining tolerances typically range from ±0.05 mm to ±0.01 mm, with advanced setups achieving ±0.005 mm for critical aerospace or medical parts. This level of precision is essential for applications such as tight-fitting assemblies or high-performance components.

For example, aerospace components produced from Rene 104 are machined to exacting tolerances to ensure proper fit within turbine systems. Similarly, parts for medical devices must meet rigorous dimensional standards to comply with industry regulations.

In contrast, 3D printing tolerances are more variable and depend on the specific process. Typical tolerances for industrial 3D printing range from ±0.1 mm to ±0.2 mm. While this is acceptable for design validation or non-critical features, it may not be sufficient for functional components that require precise fits.

Surface Finish Capabilities

CNC machining provides an excellent surface finish immediately after machining. A typical as-machined surface finish is around Ra 1.6–3.2 μm. Finishing processes, such as polishing, anodizing, or PVD coating, can further enhance both appearance and functionality. For example, polished aluminum 2024 parts used in consumer electronics benefit from both aesthetic appeal and corrosion resistance.

3D-printed parts generally require post-processing to improve their surface finish. Depending on the process, initial surfaces may exhibit visible layer lines or rough textures. Techniques such as tumbling, sanding, or application of finishes like lacquer coating help achieve the desired surface quality, particularly for plastic prototypes or display models.

Material Strength and Mechanical Properties

CNC machining excels when high material strength and mechanical properties are required. Machined parts retain the full isotropic strength of the base material. For instance, components machined from Hastelloy B-3 exhibit excellent corrosion resistance and mechanical stability under high-temperature and high-pressure conditions, making them suitable for oil and gas or nuclear applications.

In contrast, many 3D printed materials, especially polymers, exhibit anisotropic properties due to the layer-by-layer build process. This can result in reduced strength along the Z-axis compared to machined counterparts. Metal 3D printing technologies, such as DMLS, can produce near-isotropic parts; however, material properties may still vary from those of wrought or forged stock.

Consistency Across Batches

CNC machining offers superior consistency across multiple batches. Detailed process control, tool wear monitoring, and rigorous inspection ensure that each part matches the required specifications. This is crucial for industries such as power generation, where high reliability is non-negotiable.

For example, the precision machining of bronze C86300 bushings for heavy-duty industrial equipment ensures consistent performance across multiple production runs.

3D printing consistency is improving, but it remains sensitive to factors such as powder quality, printer calibration, and build orientation. For one-off prototypes or short runs, it provides adequate repeatability; however, for critical components, CNC machining remains the preferred choice.

Guidelines for Choosing the Right Process

When deciding between CNC machining and 3D printing, consider the following factors:

Material requirements. If high strength, heat resistance, or corrosion resistance is required, CNC machining of materials like Inconel 939 is the optimal choice.

Dimensional accuracy. For features requiring tolerances tighter than ±0.05 mm, CNC machining delivers superior precision.

Geometry complexity. For parts with organic shapes, internal channels, or undercuts, 3D printing may be a better choice. For example, consumer product enclosures with intricate aesthetics are often efficiently produced with additive manufacturing.

Production volume. For quantities above 50–100 units, CNC machining typically offers better cost-efficiency and consistency. For smaller volumes or one-offs, 3D printing minimizes upfront costs.

Surface finish. CNC machined components, such as bronze C51000 electrical contacts, deliver a superior surface finish without extensive post-processing. 3D printed parts often require secondary finishing steps.

Future Trends in Hybrid Manufacturing

The future of manufacturing is moving toward hybrid workflows that combine the strengths of both technologies. At Neway, engineers are increasingly leveraging this approach to deliver optimized solutions for clients in the aerospace, medical, robotics, and industrial markets.

For example:

Robotics components may use 3D printing for lightweight housings while relying on CNC machining for precision aluminum 4045 structural frames.

Medical device assemblies may combine 3D-printed PEEK surgical guides with CNC-machined stainless steel SUS317 implant components.

Power generation equipment is increasingly integrating 3D-printed cooling features into CNC-machined high-temperature superalloy components for improved efficiency.

Conclusion

Both CNC machining and 3D printing offer unique strengths. By understanding the capabilities and limitations of each process, engineers and procurement teams can make informed decisions that optimize cost, performance, and lead time.

Partnering with a versatile supplier like Neway Machining, which offers integrated CNC machining and 3D printing services, enables customers to adopt a hybrid approach tailored to their product’s specific needs, whether for prototyping, low-volume production, or scaling to mass manufacturing.