Ceramic CNC Machining Service: Everything You Need to Know

Introduction: Engineering Ceramics — When Exceptional Materials Meet Precision Machining

In today’s high-end manufacturing landscape, engineering ceramics are redefining performance boundaries across many critical applications with their unique combination of properties. As a materials engineer at Neway, I have had the privilege of witnessing the full journey of ceramic materials from laboratory research to large-scale industrial production. Ceramics not only offer hardness, wear resistance, and chemical stability far beyond what metals can achieve, but also deliver excellent high-temperature performance and biocompatibility. However, these outstanding properties also come with tremendous machining challenges — and this is exactly where our specialized ceramic CNC machining services create value.

From medical implants to semiconductor manufacturing equipment, and from aerospace engine components to high-end metrology instruments, engineering ceramics play an irreplaceable role in a wide range of industries. But to fully unlock their potential, we must overcome the machining difficulties posed by their inherently hard and brittle nature. At Neway, through years of technological accumulation and process innovation, we have successfully applied precision CNC machining technologies to a variety of engineering ceramics, providing customers with end-to-end solutions from material selection to finished part delivery.

Characteristics of Engineering Ceramics: Outstanding Advantages with Machining Challenges

Exceptional Hardness, Wear Resistance, and Chemical Stability

The most prominent feature of engineering ceramics is their extremely high hardness, typically reaching HRA 80–90, which gives ceramic components exceptional wear resistance. Under comparable working conditions, ceramic parts can achieve service lives several to dozens of times longer than metal parts. At the same time, ceramics exhibit excellent resistance to most acids, alkalis, and salts, making them particularly suitable for use in harsh chemical environments. In addition, ceramic materials offer excellent biological inertness, securing their position as key materials in medical implant applications.

Low Density, High Stiffness, and Excellent Thermal Properties

Compared with modern metallic materials, engineering ceramics have relatively low density (typically 3–6 g/cm³) and very high elastic modulus (300–400 GPa), meaning that for the same weight, ceramic components can provide significantly higher structural stiffness. In terms of thermal behavior, ceramics exhibit low coefficients of thermal expansion and good thermal stability. Some ceramics, such as silicon nitride, also demonstrate outstanding thermal shock resistance, allowing them to withstand rapid temperature changes without cracking.

Machining Challenges from Intrinsic Brittleness: Cracks, Chipping, and Tool Wear

Despite their many advantages, the inherent hardness and brittleness of ceramics pose major machining challenges. Material removal occurs primarily through brittle fracture, which easily leads to microcracks and edge chipping. At the same time, their high hardness causes rapid tool wear, making conventional processes and cutting parameters completely unsuitable. These issues demand dedicated machining strategies and tooling solutions — the core technical strength behind our precision machining services.

Neway’s Ceramic CNC Machining Capabilities: Solutions Tailored for Hard and Brittle Materials

CNC Machines and Dedicated Tooling Optimized for Ceramics

Our ceramic machining centers have been specially upgraded to provide higher rigidity, more stable cooling systems, and enhanced precision in motion control. For cutting tools, we primarily use diamond tooling, including electroplated diamond tools and polycrystalline diamond (PCD) tools. Depending on the ceramic material and machining requirements, we select diamond tools with different grit sizes, concentrations, and bond types to achieve the optimal balance between machining efficiency and surface quality.

Specialized Fixturing and Process Techniques to Minimize Fracture Risk

Ceramic components are prone to cracking due to stress concentration during the clamping process. We have developed various dedicated fixturing solutions, including low-stress fixtures, contour-support fixtures, and vacuum chucks, to ensure uniform distribution of clamping forces. In terms of process parameters, we use strategies such as shallow depth of cut, high spindle speed, and low feed rate, combined with high-response servo systems to precisely control cutting forces and significantly reduce fracture risk during machining.

Strict Process Control to Ensure Dimensional Accuracy and Surface Integrity

We have established a comprehensive process control system specifically for ceramic machining. From incoming material inspection to in-process monitoring to final quality verification, every step is governed by stringent standards. Through precision grinding operations and optimized parameters, we can achieve dimensional tolerances of ±0.005mm and surface roughness as low as Ra 0.2μm, meeting even the most demanding application requirements.

Machining Characteristics and Application Guidelines for Common Engineering Ceramics

Zirconia: High-Toughness Ceramic for Wear-Resistant Structural Components

Zirconia ceramics feature transformation toughening mechanisms and offer the highest fracture toughness among engineering ceramics. Machining zirconia requires precise control of cutting temperature to avoid unwanted phase transformations that may cause dimensional changes. Zirconia is ideal for components that require both excellent wear resistance and moderate impact toughness, such as bearings, seal rings, and medical implants.

Alumina: The Preferred Choice for High Hardness and Electrical Insulation

Alumina ceramics are among the earliest engineering ceramics to be commercialized, offering excellent electrical insulation, high hardness, and relatively low cost. When machining alumina, we pay particular attention to edge quality to prevent chipping. This material is widely used in electronic insulators, wear-resistant linings, and chemical seals.

Silicon Nitride: Outstanding Thermal Shock Resistance and Mechanical Strength

Silicon nitride ceramics combine high strength, good toughness, and excellent thermal shock resistance, making them ideal for high-temperature structural applications. When machining silicon nitride, we employ dedicated tool geometries and cooling strategies to secure superior surface integrity. Typical applications include bearings, cutting tools, and engine components.

Other Advanced Ceramics: Aluminum Nitride, Silicon Carbide, and More

In addition to the above mainstream ceramics, we are also capable of machining advanced materials such as aluminum nitride (AlN) and silicon carbide (SiC). Aluminum nitride offers excellent thermal conductivity and electrical insulation, making it ideal for electronic packaging. Silicon carbide, on the other hand, features extremely high hardness and thermal stability, making it suitable for parts exposed to extremely harsh environments.

Core Processes in Ceramic CNC Machining: Turning, Milling, Drilling, and Grinding

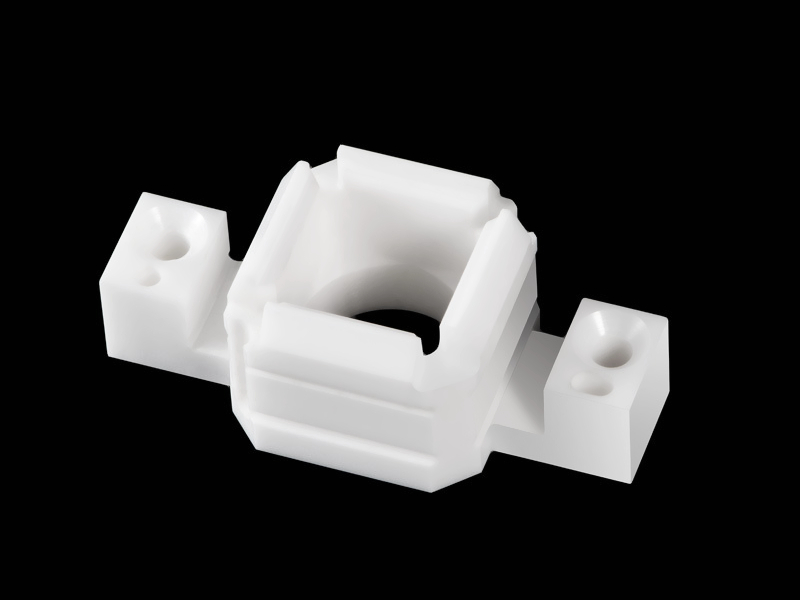

Ceramic CNC Milling: Forming Complex Geometries

Milling is one of our most frequently used methods for ceramic machining and is suitable for producing parts with complex profiles and three-dimensional features. During ceramic milling, we use small stepovers and optimized cutting strategies, combined with effective coolant flushing to remove chips and prevent surface damage. For ceramic parts in the prototype development stage, milling is the preferred process to validate design feasibility.

Ceramic CNC Turning: Precision Machining of Rotational Parts

For rotational ceramic components such as bearings and sleeves, we apply precision turning processes. Unlike metal turning, ceramic turning requires diamond tools with negative rake angles to remove material under compressive stress-dominated cutting conditions. By optimizing tool paths and cutting parameters, we can achieve mirror-like surface finishes and micrometer-level dimensional accuracy.

Ceramic Drilling and Tapping: The Challenge of Micro Holes and Threads

Drilling small holes and cutting threads in ceramics is an extremely challenging task. We use specially designed diamond drills and taps, combined with precise alignment systems and stable feed control, to ensure bore quality and thread integrity. For high-aspect-ratio micro holes, we may also employ EDM as a complementary process, depending on the specific design and material.

Ceramic Grinding: Achieving Ultra-High Precision and Surface Finish

Grinding is the primary finishing method for ceramics. Using diamond grinding wheels with resin or metal bonds, along with fine dressing and optimized grinding parameters, we achieve sub-micron form accuracy and nanometer-level surface roughness. This process is especially suitable for critical functional surfaces such as ceramic seal rings and bearing raceways.

Beyond Machining: Post-Processing and Quality Assurance for Ceramic Components

Precision Machining and Dimensional Control After Sintering

Most engineering ceramics are formed through powder compaction and sintering, a process that inevitably introduces shrinkage and deformation. Post-sintering finishing is therefore required to achieve final dimensions. Through precision grinding and polishing, we accurately control final size and geometric tolerances to ensure full compliance with design specifications.

Edge Chamfering and Surface Refinement to Enhance Strength

Edge quality has a direct impact on the strength and reliability of ceramic components. We use dedicated chamfering and polishing techniques to remove microcracks and defects generated during machining, significantly improving mechanical strength. For parts with special requirements, we offer professional polishing services to ensure optimal surface quality.

Advanced Inspection Methods to Ensure Performance Compliance

We employ a range of advanced inspection techniques to guarantee the quality of ceramic components. In addition to conventional dimensional checks, we use ultrasonic testing to detect internal defects, microscopes to examine surface microstructures, and, when necessary, mechanical testing and performance verification. For parts requiring full traceability, we apply permanent identification using laser marking.

In-Depth Industry Applications: How Ceramic Components Drive Innovation

Medical Devices: Surgical Tools, Implants, and Dental Components

In the medical device sector, zirconia ceramics are widely used in artificial joints, dental implants, and surgical instruments due to their excellent biocompatibility and wear resistance. The ceramic femoral heads and acetabular cups we manufacture offer extremely low wear rates and excellent osseointegration, significantly extending implant service life and improving patient quality of life.

Aerospace: Wear-Resistant Bushings, Insulators, and Sensor Housings

In the aerospace industry, ceramic components are used in engine systems, navigation equipment, and thermal protection structures. Our silicon nitride bearings and alumina insulators operate reliably under extreme conditions of high speed and high temperature, contributing to the safety and durability of aerospace systems.

Semiconductor and Electronics: Wafer Carriers, Insulating Fixtures, and Plasma Components

In the semiconductor industry, alumina and aluminum nitride ceramics are key materials for their superior electrical insulation and high-temperature stability. The wafer handling arms and plasma chamber liners we produce deliver high dimensional stability and purity, ensuring precise process control and high yield in semiconductor manufacturing.

The Core Value of Choosing Neway for Ceramic CNC Machining

At Neway, we regard ceramic machining as an art that demands continuous exploration and innovation. Our engineering team not only masters machining technologies but also has deep expertise in materials science, enabling us to design optimal process solutions based on the intrinsic properties of each ceramic material. From initial prototype design through to full-scale production, we work closely with our customers to ensure that every stage meets the highest quality standards.

Our one-stop service approach ensures that customers receive comprehensive technical support. Whether it is a simple alumina insulator or a complex silicon nitride structural component, we provide end-to-end services covering material selection, process design, machining, and quality inspection. This integrated model not only improves production efficiency but, more importantly, ensures consistency and reliability in product performance.

At Neway, we believe that every ceramic component serves an important purpose for our customers. Whether it is a life-saving artificial joint or a component enabling space exploration, we apply the same level of professionalism and craftsmanship. We look forward to working with you to transform the exceptional properties of ceramics into tangible competitive advantages in your products.

FAQ

What levels of tolerance and surface finish can be achieved with ceramic CNC machining?

How do you prevent cracking or chipping of ceramic materials during machining?

Do ceramic parts require additional post-processing after machining?

What specific expertise does Neway have in machining zirconia and alumina ceramics?

What are the main cost drivers in ceramic CNC machining projects?