5-Axis CNC Machining of Aluminum 6063 Battery Enclosures for BYD Electric Vehicles

Project Background: High-Precision Battery Enclosure for EV Power Modules

BYD, a global leader in electric vehicle manufacturing, required a lightweight, corrosion-resistant, and precisely machined battery housing for its latest EV power system. The housing needed to meet strict flatness and sealing requirements to ensure thermal and structural reliability under demanding automotive conditions. Neway was selected to provide an integrated CNC machining and surface finishing solution.

Why Aluminum 6063 for EV Battery Enclosures

Aluminum 6063 provides excellent corrosion resistance, thermal conductivity, and surface finish quality, making it ideal for battery housing in EV applications.

Property | Value |

|---|---|

Thermal Conductivity | ~200 W/m·K |

Yield Strength | ≥160 MPa |

Elongation | ≥10% |

Surface Finish Suitability | Excellent for anodizing and blasting |

This alloy also allows precise dimensional control, essential for sealing interfaces and modular assembly. Learn more about Aluminum 6063 CNC Machining.

Machining Workflow

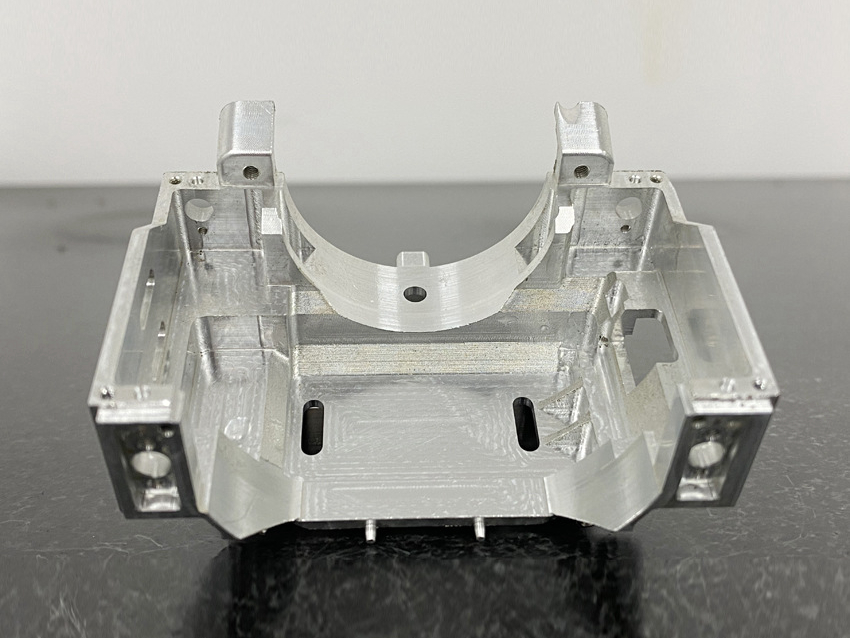

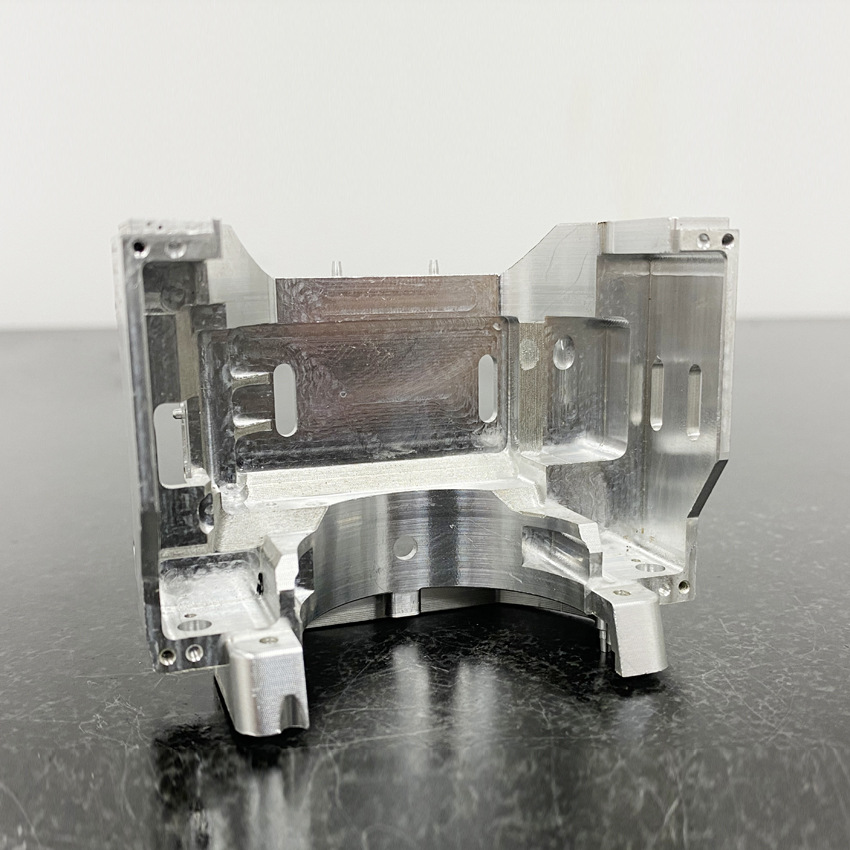

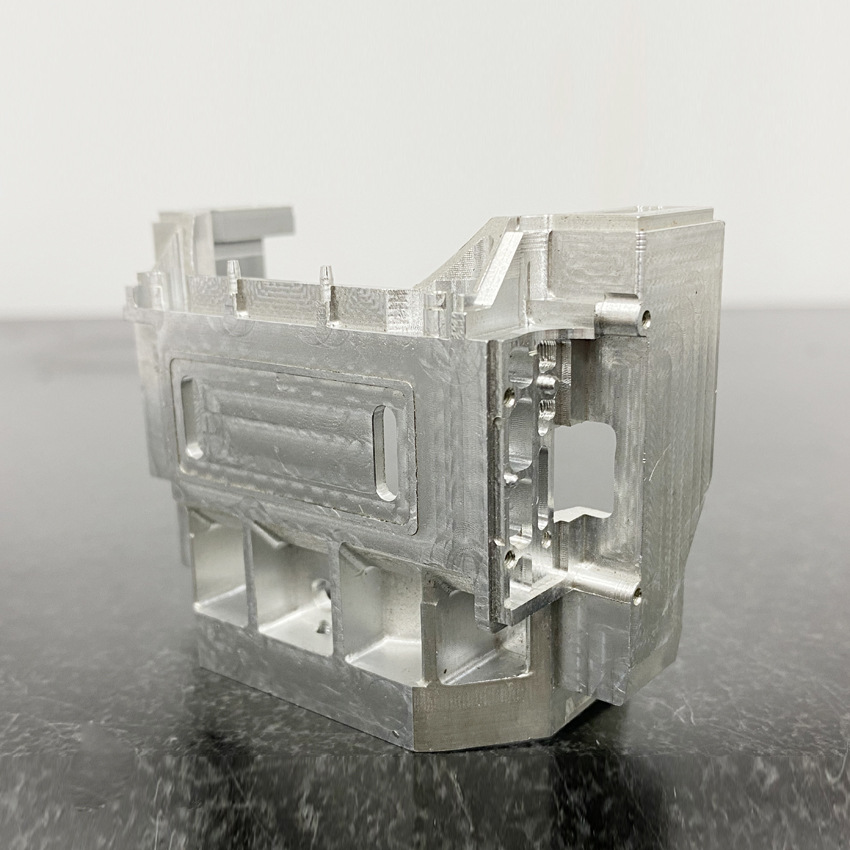

3-Axis CNC Rough Milling

Bulk material was removed using 3-axis CNC milling, shaping the internal cavity and reserving machining allowance for high-precision surfaces.

5-Axis CNC Precision Machining

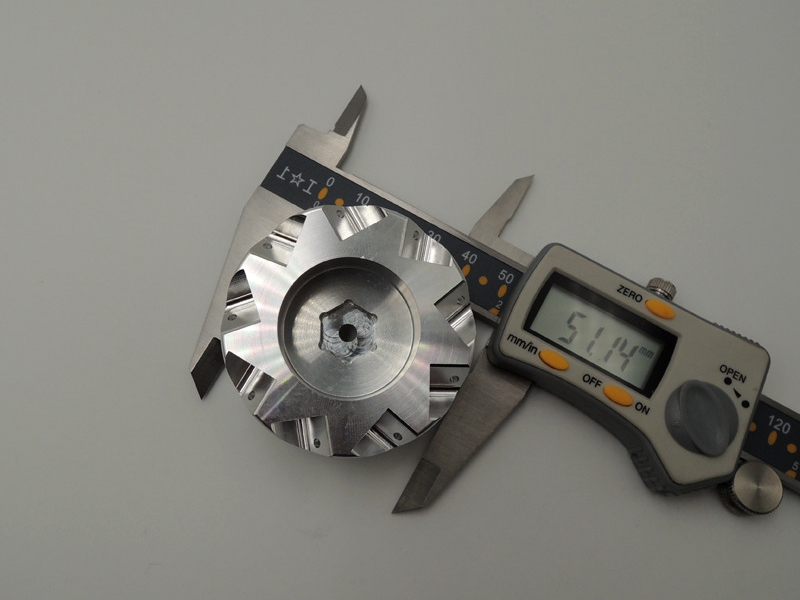

Critical sealing flanges, locking slots, and sensor interfaces were finished in a single setup using 5-axis CNC machining. Flatness was maintained within ±0.015 mm, and assembly features were positioned with ±0.02 mm repeatability.

Surface Finishing

To improve corrosion resistance and meet BYD’s aesthetic and functional requirements, the following surface treatments were applied:

Sandblasting: Produced a uniform matte finish (~Ra 1.3 μm) and improved anodizing adhesion

Anodizing: Applied a Type II clear anodic layer (thickness ~12 μm) for oxidation protection, increased surface hardness, and electrical insulation

Quality Control

CMM Inspection: All sealing planes and alignment holes were measured with ±5 μm precision

Anodizing Thickness Test: Verified using eddy current method, consistent across all housing surfaces

Flatness & Warp Control: Housing bases were checked on a granite surface plate with gap gauges ≤0.02 mm

Production Results

Neway delivered a batch of 2,000 battery housings with 100% pass rate on structural and sealing dimensional checks. BYD engineers praised the consistency of the anodized finish, which matched their thermal and aesthetic expectations. The housings integrated seamlessly into battery packs with no assembly rework required.

Why Neway for CNC Machined EV Battery Components

Aluminum CNC Machining: Enables precision on multi-face geometries without repositioning, reducing tolerance stack-up

Precision Machining Service: Ensures critical sealing and fitment dimensions are maintained

One-Stop Manufacturing Service: Seamless integration of machining, finishing, inspection, and delivery from a single source

FAQs

What are the tolerance standards for EV battery enclosure sealing surfaces?

How does Aluminum 6063 compare to 6061 in thermal and corrosion resistance?

What is the ideal anodizing thickness for automotive-grade aluminum parts?

How does 5-axis machining benefit battery housing production?

Can sandblasting improve surface durability for automotive anodized parts?