Металл против пластика в ЧПУ-обработке: окончательное руководство по выбору материала

Введение

В мехобработке на станках с ЧПУ выбор материала является ключевым фактором, влияющим на прочность, долговечность, точность и себестоимость изделия. Для аэрокосмической отрасли, медицины или бытовой электроники понимание того, когда выбирать металл, а когда пластик, помогает обеспечить оптимальные показатели и контролировать бюджет. В этом руководстве рассматриваются основные критерии выбора, чтобы инженеры и закупщики могли принимать взвешенные решения по нестандартным деталям.

Изучите уникальные преимущества металлических деталей, обрабатываемых на ЧПУ, и универсальность пластиковых компонентов после мехобработки для самых разных производственных задач.

Металлы для мехобработки на ЧПУ: прочность, термостойкость и несущая способность

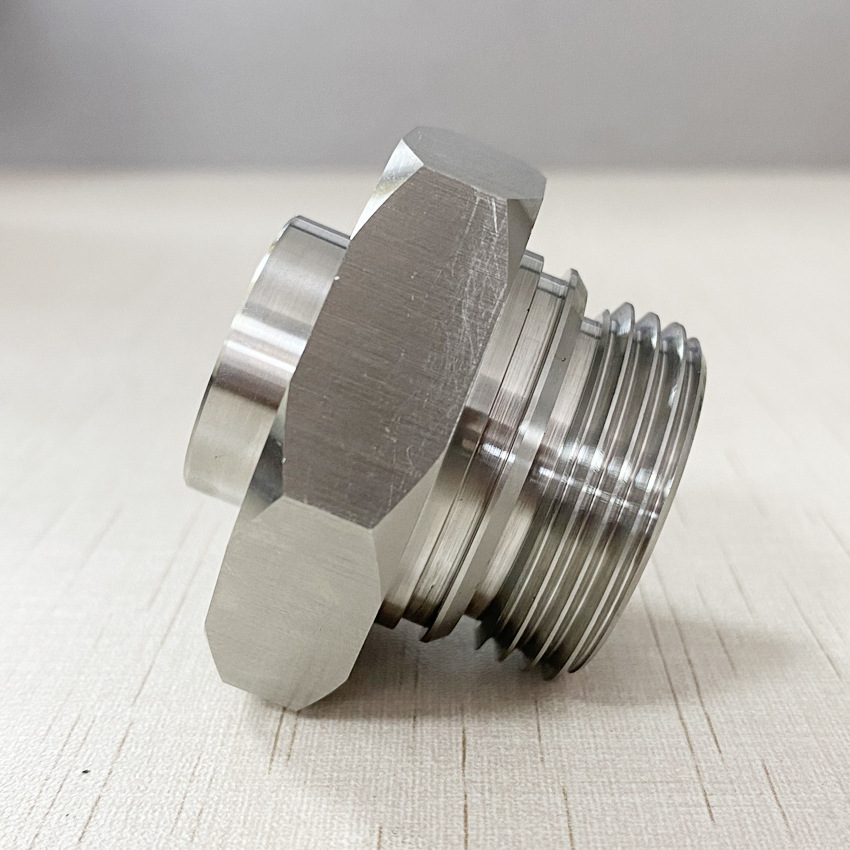

Мехобработка металлов на ЧПУ оптимально подходит для задач, где требуются высокая структурная прочность, работа при повышенных температурах и стойкость к усталостным нагрузкам. Наиболее часто используются алюминий, нержавеющие стали, титан, медные сплавы и суперсплавы, такие как Inconel и Hastelloy.

Основные металлы, применяемые при мехобработке на ЧПУ

Материал | Предел текучести (МПа) | Теплопроводность (Вт/м·K) | Плотность (г/см³) | Типичные применения |

|---|---|---|---|---|

Aluminum 6061-T6 | 276 | 167 | 2,7 | Рамы роботов, корпуса электроники |

Stainless Steel SUS304 | 215 | 16,2 | 7,93 | Медицинские и пищевые компоненты |

Titanium Ti-6Al-4V | 880 | 6,7 | 4,43 | Аэрокосмические конструкции, импланты |

Inconel 718 | 1030 | 11,4 | 8,19 | Высокотемпературные турбинные детали |

Copper C110 (TU0) | 69 | 385 | 8,96 | Электрические соединители |

Каждый металлический сплав имеет свои преимущества, ориентированные на определённые отрасли. Например, мехобработка Inconel 718 на ЧПУ широко используется для лопаток турбин в авиакосмической сфере благодаря пределу текучести 1030 МПа и стойкости к окислению при температурах выше 700°C.

Поверхностные обработки для увеличения ресурса металлических деталей

Поверхностная инженерия повышает коррозионную стойкость, износостойкость и улучшает внешний вид металлических деталей после мехобработки. Анодирование часто применяется к алюминию для образования твёрдого коррозионно-стойкого оксидного слоя. Для нержавеющих сталей и суперсплавов электрополировка обеспечивает гладкую пассивированную поверхность, идеальную для медицины и чистых помещений.

Другие типы защитных покрытий включают:

PVD-покрытия для декора и износостойкости.

Чёрное оксидирование стали для снижения бликов и повышения коррозионной стойкости.

Хромирование для увеличения твёрдости поверхности и улучшения внешнего вида.

Эти обработки существенно продлевают срок службы деталей, особенно в энергетике и морской технике.

Стоимость и обрабатываемость

Несмотря на высокие эксплуатационные характеристики, металлы обычно дороже по сырью и сложнее в обработке:

Титан и суперсплавы отличаются низкой обрабатываемостью и высоким износом инструмента, что увеличивает время цикла.

Алюминий и латунь обладают отличной обрабатываемостью и экономичны для задач средней по уровню прочности.

Выбор сплава всегда связан с балансом между характеристиками и эффективностью производства. Например, мехобработка алюминия 7075 на ЧПУ позволяет получить высокую прочность при малом весе, что идеально для авиации и робототехники.

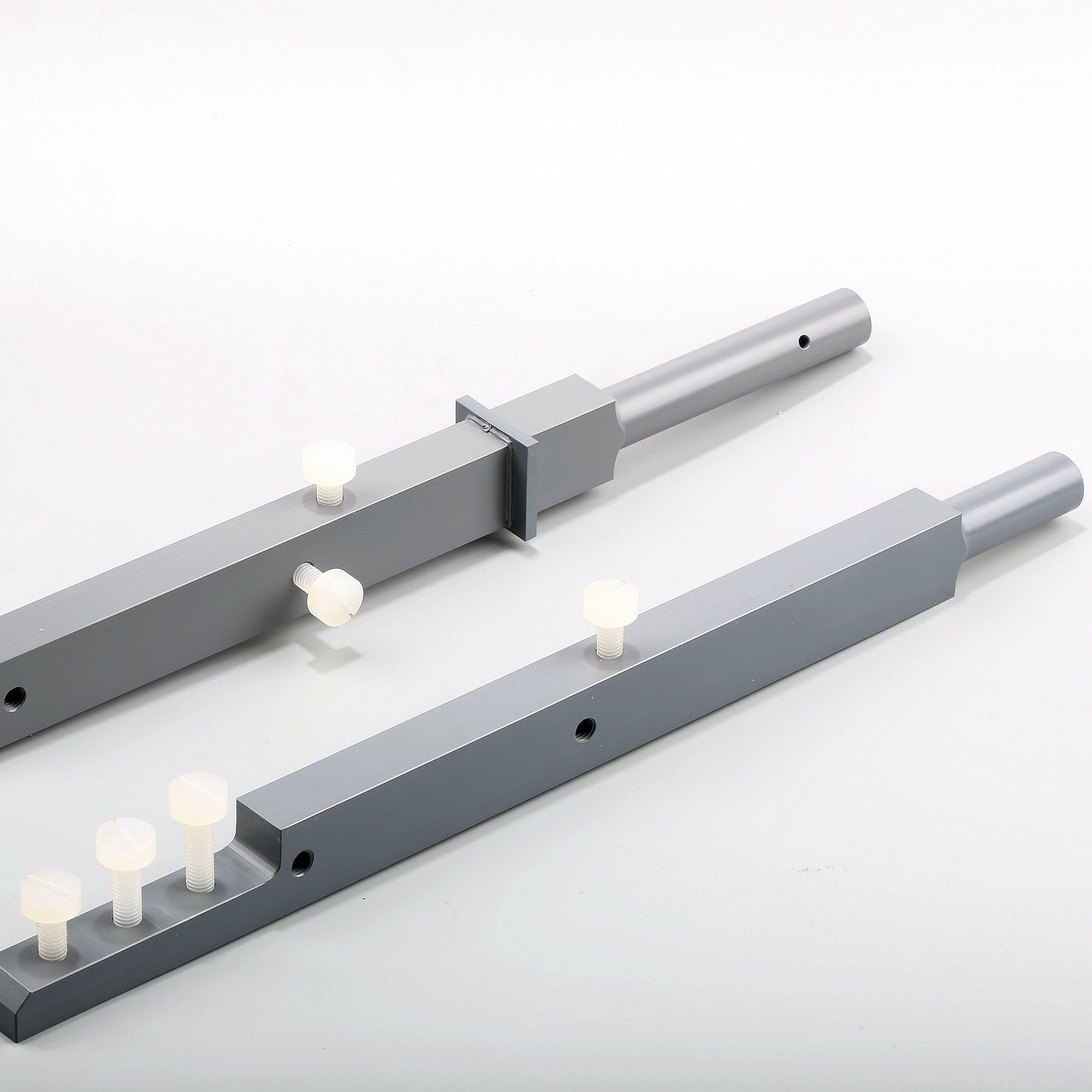

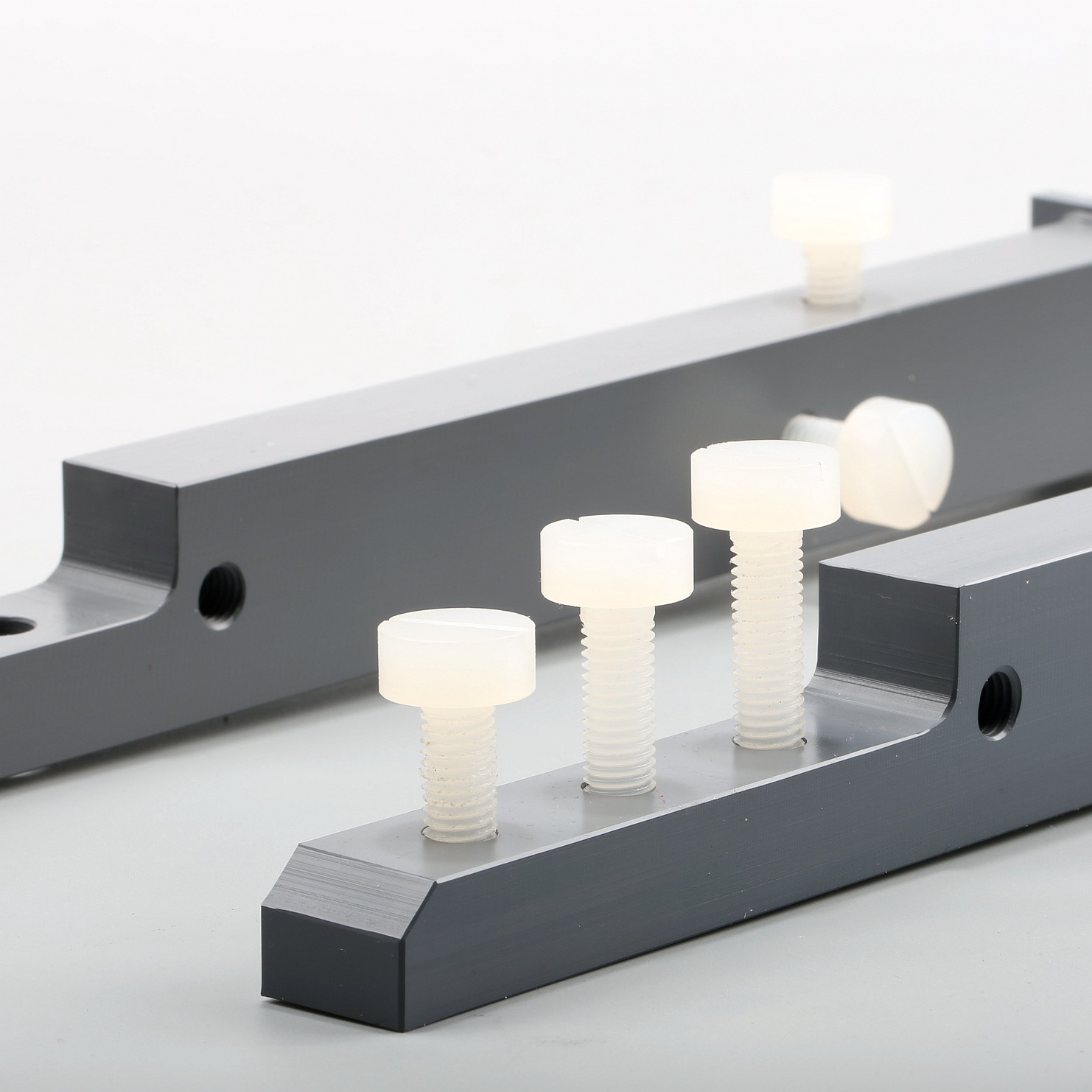

Пластики для мехобработки на ЧПУ: малый вес, экономичность и химстойкость

Пластики — полноценная альтернатива металлам там, где приоритетом являются снижение веса, устойчивость к коррозии и сложная геометрия деталей. Мехобработка пластика на ЧПУ позволяет получать точные изделия без затрат и сроков, связанных с изготовлением пресс-форм, что особенно выгодно для прототипирования и мелко–/среднесерийного производства.

Наиболее распространённые пластики для мехобработки на ЧПУ

Материал | Предел прочности при растяжении (МПа) | Рабочая температура (°C) | Ключевые свойства | Применения |

|---|---|---|---|---|

ABS | 43 | 80 | Ударная вязкость, низкая стоимость | Корпуса потребительских изделий |

Nylon (PA6) | 75 | 120 | Износостойкость, хорошая обрабатываемость | Шестерни, втулки |

POM (Delrin) | 70 | 100 | Низкий коэффициент трения, жёсткость | Кулачки, подшипниковые элементы |

PTFE (Teflon) | 21 | 260 | Химическая инертность | Уплотнения, изоляторы |

PEEK | 95 | 250 | Высокая прочность, огнестойкость | Аэрокосмос, медицина |

Инженерные пластики, такие как детали из PEEK после мехобработки, выдерживают длительную работу при температурах выше 200°C и обладают отличной размерной стабильностью, что делает их идеальными для сложных задач в авиакосмической и медицинской отраслях.

Поверхностные обработки пластиковых деталей после ЧПУ

Во многих случаях пластики не требуют дополнительной обработки поверхности, однако такие процессы, как UV-покрытие, лакирование и тефлоновые покрытия, повышают износостойкость, стойкость цвета и химическую устойчивость. Например, лакировка часто используется для смесей PC-ABS, обеспечивая защитный глянец и премиальный внешний вид в потребительских товарах.

Пластиковые детали также могут подвергаться виброобработке и удалению заусенцев для устранения следов резания, что важно для визуально открытых корпусов и панелей.

Преимущества по стоимости и срокам

По сравнению с металлами, пластики предлагают:

Более низкую стоимость материала (часто менее 50% стоимости металлических аналогов);

Сокращённое время обработки за счёт меньшего сопротивления резанию;

Меньшую зависимость от сложных траекторий и высокопроизводительного инструмента.

Эти преимущества делают мехобработку пластика особенно привлекательной для быстрого прототипирования и деталей сложной формы, для которых не требуется высокая прочность на растяжение.

Так, мехобработка ABS на ЧПУ широко используется в потребительской электронике благодаря ударной вязкости и низкой цене. В сочетании с UV-покрытием материал обеспечивает как функциональность, так и привлекательный внешний вид.

Экологические и нормативные требования

В медицине и пищевой промышленности пластиковые материалы должны соответствовать требованиям биосовместимости и нормам FDA или аналогичных стандартов. Медицинский PEEK и PTFE часто применяются из-за устойчивости к стерилизации, контактам с биожидкостями и агрессивным дезинфектантам.

В электронике, напротив, важна огнестойкость — например, соответствие UL 94 V-0. Этого показателя часто достигают с помощью материалов, таких как поликарбонат или PEEK.

Сравнительный анализ характеристик: металлические и пластиковые детали после ЧПУ

Понимание компромиссов между металлом и пластиком при мехобработке на ЧПУ критически важно для грамотного проектирования. Ниже приведено сравнение ключевых параметров, важных для инженеров и специалистов по закупкам:

Свойство | Металлические детали после ЧПУ | Пластиковые детали после ЧПУ |

|---|---|---|

Механическая прочность | Высокая (до 1500 МПа) | Средняя (обычно <150 МПа) |

Термостойкость | Отличная (до ~1000°C для суперсплавов) | Ограниченная (макс. ~250°C для PEEK) |

Химическая стойкость | От средней до высокой в зависимости от сплава | Очень высокая для PTFE, PEEK, PVDF |

Электроизоляция | Проводники (за редкими исключениями) | Отличные диэлектрики (например, PTFE) |

Обрабатываемость | Различная: алюминий — лёгкий в обработке, Inconel — сложный | В целом хорошая, низкий износ инструмента |

Масса | Большая (например, сталь ~7,8 г/см³) | Малый вес (например, POM ~1,4 г/см³) |

Коррозионная стойкость | Высокая у нержавеющих сталей, Inconel и др. | Часто присуща материалу изначально |

Варианты финишной обработки | Широкие: анодирование, гальваника, полировка | Ограниченные, но эффективные: UV-покрытие, лак и др. |

Стоимость (материал + обработка) | Средняя–высокая | Низкая–средняя |

Устойчивость к внешней среде | Подходит для значительных нагрузок и термоциклов | Идеальна при воздействии химии, влаги и малых нагрузок |

Для деталей, работающих при экстремальных нагрузках и температурах, таких как корпусы турбин или силовые элементы двигателя, металлы — например, Inconel 625 — фактически незаменимы. В то же время для лёгких электрощитков или медицинских устройств PTFE или Delrin (POM) обеспечивают экономичное и полностью коррозионно-стойкое решение.

Когда выбирать металл для мехобработки на ЧПУ

Металлы являются предпочтительным вариантом, если:

Необходима высокая несущая способность (например, в аэрокосмических и автомобильных силовых конструкциях);

Детали работают при высоких температурах, как в турбинах или выхлопных системах;

Ключевым фактором является усталостная прочность при циклических нагрузках;

Финишные покрытия, такие как термостойкие покрытия, должны дополнительно повышать износостойкость и устойчивость к окислению.

Пример из практики: мехобработка титана на ЧПУ для авиационных конструкций демонстрирует, как Ti-6Al-4V обеспечивает высокую грузоподъёмность при значительном снижении массы в авиации.

Когда выбирать пластик для мехобработки на ЧПУ

Пластик целесообразен, если:

Требуется электроизоляция (например, корпуса и элементы электроники);

Предполагается значительное воздействие химически агрессивной среды или влаги, как в лабораторном оборудовании;

Важно обеспечить малый вес деталей и возможность быстрых изменений конструкции;

Бюджет ограничен, а объём производства — малый или прототипный.

Пример из практики: мехобработка нейлона (PA) на ЧПУ часто применяется для износостойких деталей, таких как втулки и направляющие, благодаря высокому самосмазочному эффекту и низкой стоимости оснастки.

Рекомендации по выбору материала для разных отраслей

Выбор между металлом и пластиком при мехобработке на ЧПУ должен соответствовать специфике отрасли. Ниже приведён обзор рекомендуемых материалов по направлениям:

Отрасль | Рекомендуемые материалы | Обоснование |

|---|---|---|

Авиакосмическая | Высокое отношение прочности к массе, стабильность при высоких температурах | |

Медицинские изделия | Биосовместимость и коррозионная стойкость | |

Нефтегазовая отрасль | Химическая стойкость и устойчивость к высоким давлениям | |

Потребительские товары | Качественный внешний вид и удобство прототипирования | |

Автоматизация и робототехника | Лёгкость, высокая прочность и низкое трение |

Логика выбора материала для мехобработки на ЧПУ

Для предварительного подбора можно использовать следующий алгоритм:

Будет ли деталь нести значительную механическую нагрузку?

Да → Рассматривать металл

Нет → Перейти к шагу 2

Нужна ли электроизоляция?

Да → Выбрать пластик (например, PTFE, PC)

Нет → Перейти к шагу 3

Является ли снижение массы приоритетом?

Да → Использовать пластик или лёгкий металл (например, алюминий 6061)

Нет → Рассматривать нержавеющие стали или суперсплавы

Будет ли деталь работать в агрессивной химической или влажной среде?

Да → Выбрать пластик или коррозионно-стойкие металлы (например, Hastelloy)

Нет → Выбирать по балансу «стоимость / характеристики»

Такой подход особенно эффективен в сочетании с проработанными чертежами и функциональными допусками, используемыми для точного расчёта стоимости.

Заключение

Нельзя однозначно сказать, что металл или пластик «лучше» для мехобработки на ЧПУ: каждый материал решает свои задачи в зависимости от условий эксплуатации и требований проекта. Металлы при мехобработке обеспечивают непревзойдённую прочность, усталостную стойкость и термостойкость. Пластики, в свою очередь, выигрывают по массе, устойчивости к коррозии и гибкости при прототипировании.

Понимая свойства каждого материала и сопоставляя их с требованиями конкретной отрасли, инженеры и закупщики могут оптимизировать стоимость, характеристики и сроки поставки. Для критичных деталей финишная обработка и доработка конструкции дополнительно помогают «подогнать» свойства под целевое применение.

Нужны ли вам высокопрочные металлические детали на ЧПУ или быстрый выпуск пластиковых прототипов — Neway Machining предлагает комплексные решения под ваши требования по конструкции, срокам и бюджету.

Часто задаваемые вопросы

Какие типичные допуски достижимы для металлических и пластиковых деталей после обработки на ЧПУ?

Подходят ли пластиковые детали после ЧПУ для эксплуатации на улице и при воздействии УФ-излучения?

Можно ли заменить металл на пластик в уже спроектированной детали без изменения оснастки?

Чем отличается тепловое расширение у металлических и пластиковых деталей после ЧПУ?

Что выгоднее для прототипирования: мехобработка на ЧПУ из пластика или из металла?