CNC Machining of Premium Aluminum 6061 Keyboard Housings for Lenovo

Project Background: High-End Mechanical Keyboard Housing

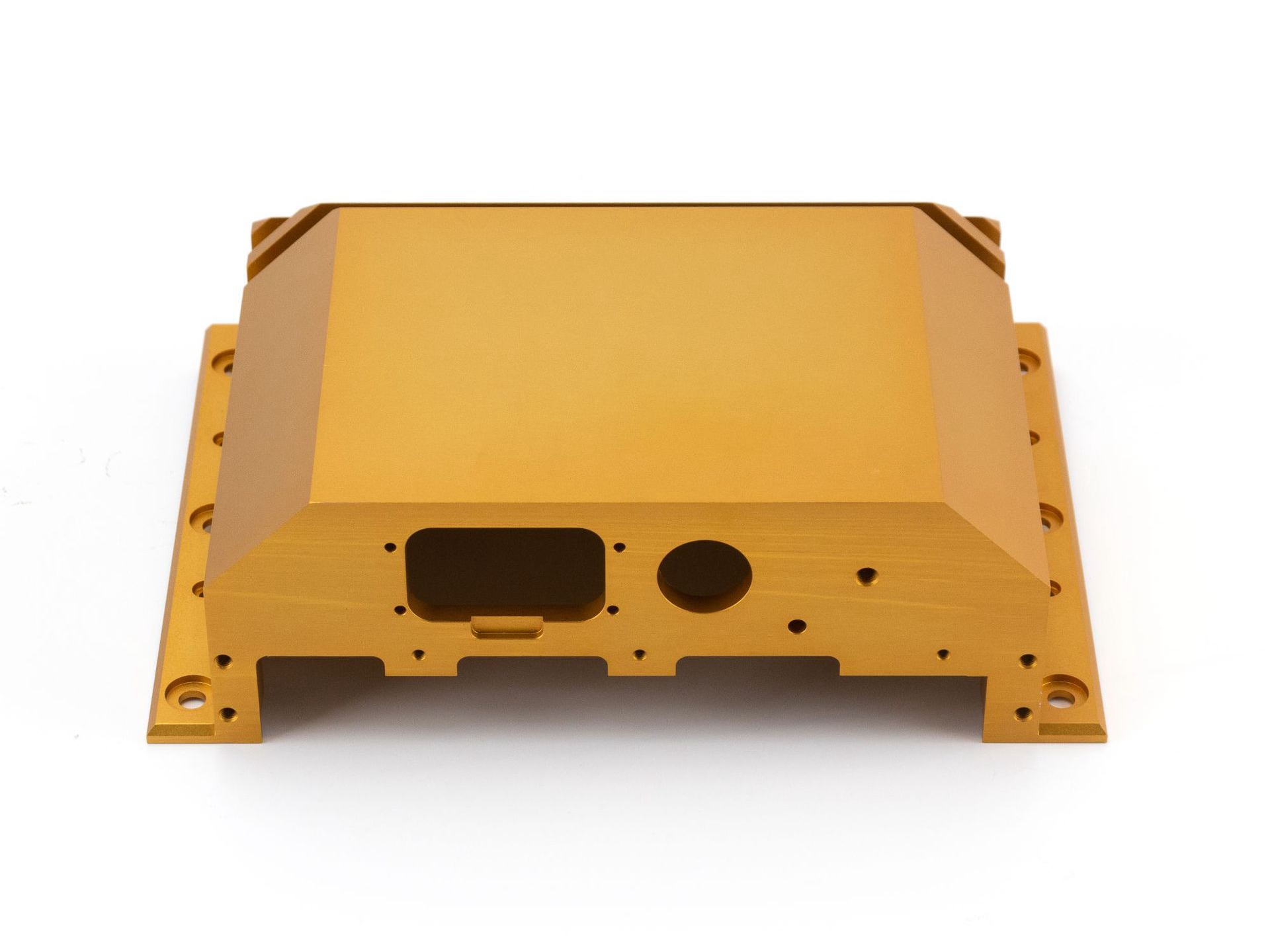

Lenovo required a premium-grade keyboard chassis for its flagship mechanical keyboard line. The part demanded high-dimensional accuracy, superior anodized surface quality, and durable branding to appeal to both professional and gaming users. Neway was selected to deliver this custom aluminum component using precision 3-axis CNC machining and integrated finishing services.

Material Overview: Why Aluminum 6061 Was Chosen

Aluminum 6061 is widely recognized for its combination of machinability, strength, and surface finish potential. For Lenovo’s mechanical keyboard chassis, it offered the following:

Property | Value |

|---|---|

Tensile Strength | ≥275 MPa |

Elongation | ≥10% |

Machinability | Excellent |

Surface Treatment Response | Ideal for anodizing and blasting |

The alloy’s stiffness-to-weight ratio and excellent response to post-processing made it ideal for both structural support and surface aesthetics. Learn more about Aluminum 6061 CNC Machining.

CNC Machining Workflow for Keyboard Housing

Step 1: 3-Axis CNC Rough Machining

Using 3-axis CNC milling, the blank aluminum block was first rough milled to remove bulk material and define internal cavities with a machining margin of 0.5 mm.

Step 2: Precision CNC Finishing

The finishing operation refined the chassis to a tolerance of ±0.02 mm, ensuring tight fitment for the PCB, stabilizers, and switch mounting plate.

Step 3: Surface Finishing

To meet Lenovo’s aesthetic and durability standards, we applied a sequence of cosmetic treatments:

Sandblasting: Delivered a uniform satin finish with Ra ≈ 1.2 μm

Anodizing: Type II anodizing (black matte), 12 μm thick for corrosion resistance and fingerprint reduction

Laser Marking: Applied logos and part identification with permanent precision

Quality Control and Visual Inspection

Dimensional Accuracy: All mounting holes, alignment slots, and exterior contours were verified with CMM and pin gauges

Surface Uniformity: Color, texture, and gloss levels were validated under D65 lighting conditions

Laser Mark Quality: Engraving depth and sharpness met ISO/IEC TR 29158 readability standards for 2D codes

Client Results and Delivery

Lenovo approved the first article sample in the first round. The batch of 1,000 units was delivered within 20 working days. Visual defects were <0.5%, and the dimensional pass rate was 100%. Feedback emphasized surface quality and consistency across batches.

Why Neway for Custom CNC Keyboard Housings

Precision Machining Service: We deliver micron-level precision required for electronics enclosures and mechanical keyboard tolerances

3-Axis CNC Milling: Cost-effective yet accurate machining for planar and prismatic parts

One-Stop Manufacturing Service: From cutting and finishing to branding and inspection, all processes are vertically integrated

FAQs

What tolerance levels can be achieved for mechanical keyboard housings using 3-axis CNC machining?

How does Aluminum 6061 compare to 5052 and 7075 for consumer electronics casings?

What is the typical anodizing thickness for keyboard surface treatment?

Can sandblasting before anodizing improve the surface texture of machined enclosures?

How durable is the laser marking after anodizing for repeated consumer use?