Microscopie métallographique pour l’évaluation de la microstructure des pièces CNC

Introduction : le pouvoir de voir le monde microscopique — le rôle clé de l’analyse métallographique dans le contrôle qualité

Dans la fabrication de haute précision, les performances macroscopiques d’un matériau sont entièrement déterminées par ses caractéristiques microstructurales. En tant qu’ingénieur matériaux chez Neway, je considère l’analyse métallographique comme un pont indispensable reliant la sélection des matériaux, les procédés de fabrication et les performances finales du produit. Grâce à la microscopie métallographique, nous pouvons observer directement le « code ADN » d’un matériau — taille des grains, composition de phase, distribution des défauts et autres caractéristiques critiques. Ces facteurs microstructuraux définissent collectivement la résistance, la ténacité, la résistance à la corrosion et la durée de vie d’un composant.

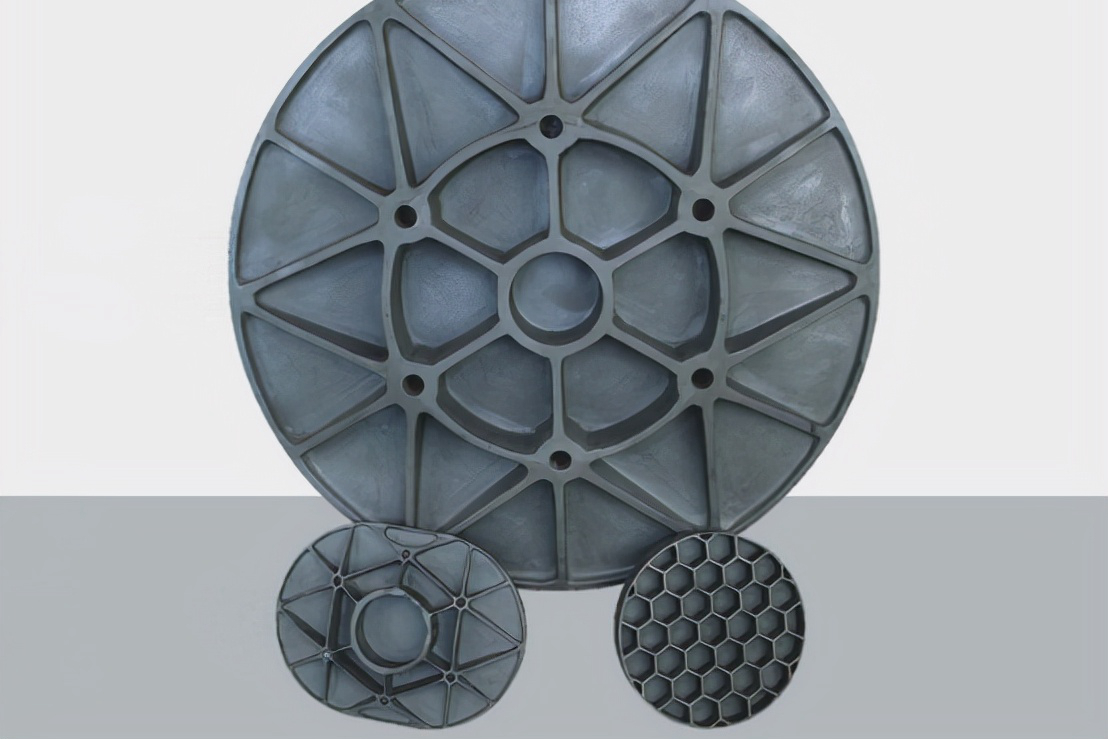

Dans l’industrie manufacturière moderne, alors que les exigences de performance des composants ne cessent de croître, se fier uniquement au contrôle dimensionnel et à l’inspection visuelle n’est plus suffisant pour un contrôle qualité de haut niveau. En particulier dans le cadre de nos services d’usinage de précision, l’analyse métallographique offre une perspective unique pour comprendre en profondeur le comportement des matériaux et aider les clients à garantir fiabilité et durabilité dès l’origine.

Dans les coulisses de la microscopie métallographique : de la préparation des échantillons à l’imagerie haute définition

Prélèvement et enrobage de précision : protéger les arêtes et zones critiques

La première étape de l’analyse métallographique consiste à obtenir un échantillon représentatif. Nos techniciens utilisent des tronçonneuses de précision pour prélever des éprouvettes dans des zones désignées de la pièce, en fonction de l’objectif d’inspection. Pour les échantillons fragiles ou nécessitant une protection des arêtes, nous adoptons des techniques d’enrobage à froid, en utilisant une résine époxy transparente sous vide afin d’enrober l’échantillon. Cela garantit l’intégrité des arêtes et facilite une manipulation sûre et stable lors des étapes de préparation ultérieures.

L’art du meulage et du polissage : obtenir une surface miroir sans rayures

Le cœur de la préparation métallographique réside dans le meulage et le polissage. À l’aide d’un système automatique de meulage et de polissage, nous passons progressivement de papiers abrasifs grossiers à des textiles de polissage fins en plusieurs étapes, en éliminant peu à peu les dommages de coupe et la déformation jusqu’à obtenir une surface parfaitement polie, comparable à un miroir. La moindre rayure ou déformation introduite à ce stade peut compromettre la précision de l’observation ; c’est pourquoi nous avons établi des procédures opératoires strictes et des contrôles qualité en cours de préparation.

Attaque chimique : révéler la microstructure cachée

Un échantillon simplement poli ne permet d’observer que les inclusions et défauts les plus évidents. Pour mettre en évidence les joints de grains et la distribution des phases, l’attaque chimique est indispensable. En fonction du type de matériau, nous sélectionnons des réactifs appropriés et contrôlons précisément le temps et la température d’attaque. Les différences de réflectivité entre les grains et les phases rendent alors la microstructure clairement visible au microscope.

Microscopie métallographique moderne : modes d’imagerie et capacités de mesure

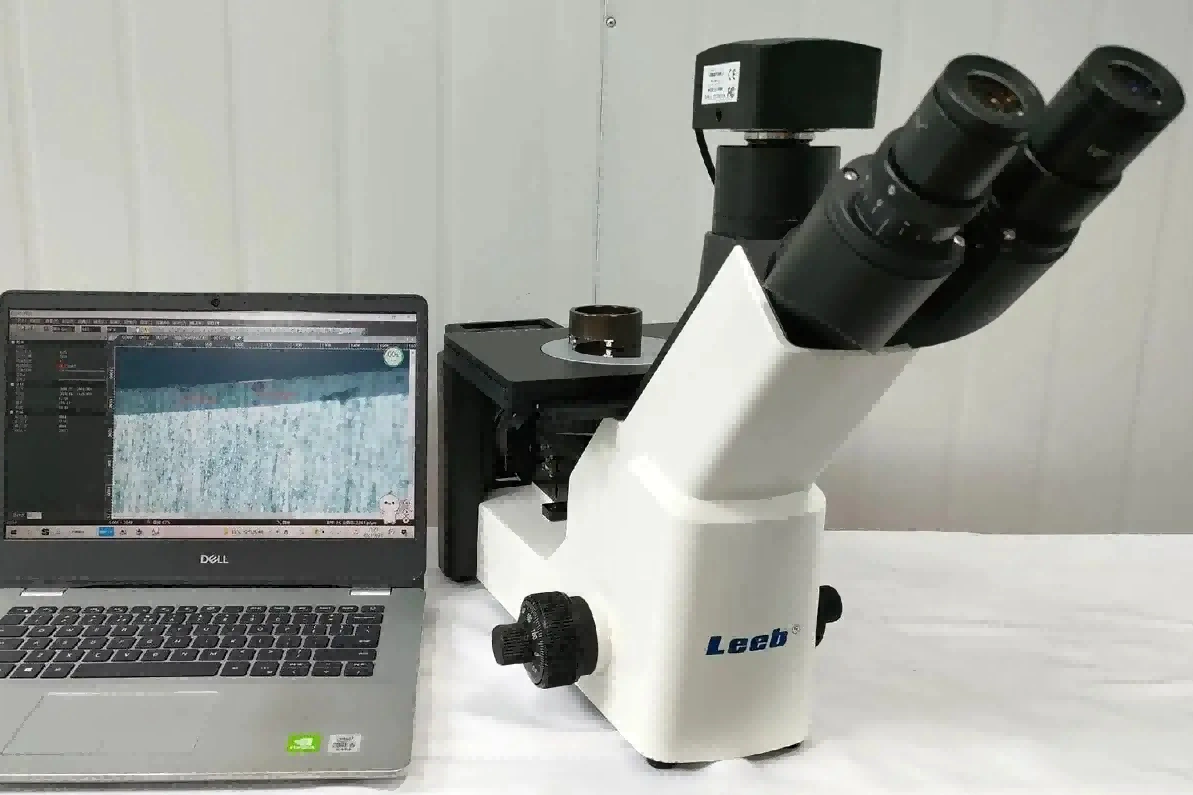

Le laboratoire de métallographie de Neway est équipé de microscopes modernes intégrant les modes champ clair, champ sombre, lumière polarisée et contraste interférentiel différentiel (DIC). Associés à des caméras numériques haute résolution et à des logiciels d’analyse d’images, ils permettent non seulement de capturer des images microstructurales nettes, mais aussi de réaliser des évaluations quantitatives telles que la cotation de la taille de grain, la mesure des fractions de phases ou la détermination de l’épaisseur de revêtements, fournissant ainsi des données objectives à l’appui des évaluations qualité.

Interpréter les microstructures : caractéristiques métallographiques standard des matériaux CNC courants

Austénite, ferrite et carbures dans les aciers inoxydables

Pour les aciers inoxydables austénitiques tels que l’acier inoxydable SUS304, la microstructure standard doit présenter des grains d’austénite homogènes, des joints de grains nets et des macles de recristallisation bien définies. Une teneur excessive en ferrite ou une précipitation importante de carbures signalent un traitement thermique inapproprié et peuvent détériorer la résistance à la corrosion. L’analyse métallographique nous permet d’évaluer avec précision l’efficacité du traitement de solution.

Taille de grain, précipités et surchauffe dans les alliages d’aluminium

Lors de l’évaluation métallographique de l’aluminium 6061-T6, nous portons une attention particulière à l’uniformité de la taille de grain et à la distribution des phases de durcissement. Des grains trop grossiers ou des précipités continus le long des joints de grains peuvent réduire les performances mécaniques. En observant la morphologie des joints de grains et la présence éventuelle de zones remoulues ou surfondues, nous pouvons déterminer avec précision si une surchauffe s’est produite pendant le traitement thermique.

Morphologie α+β et transformations de traitement thermique dans les alliages de titane

Pour les pièces issues de l’usinage d’alliages de titane, les performances dépendent fortement de la morphologie, de la taille et de la distribution des phases α et β. L’analyse métallographique nous permet d’évaluer la pertinence du traitement thermique. Une combinaison idéale de phase α équiaxe et de structure β transformée offre un bon compromis entre résistance et ténacité, tandis qu’une structure trop lamellaire ou en panier (« basket-weave ») peut indiquer la nécessité d’optimiser le procédé.

Durcissement par phase γ' et stabilité microstructurale dans les superalliages

Pour les composants issus de l’usinage de superalliages, tels que le Hastelloy C-276, l’analyse métallographique permet d’évaluer la taille, la distribution et la morphologie des phases de durcissement comme γ'. Ces caractéristiques influencent directement la résistance à haute température et la tenue au fluage. Parallèlement, nous surveillons de près la formation de phases néfastes (comme les phases TCP) afin d’éviter toute dégradation des propriétés du matériau.

Applications clés de la métallographie tout au long du processus d’usinage CNC

Contrôle des matières premières : sécuriser le premier verrou qualité

Dans notre laboratoire de métallographie, nous effectuons des contrôles par échantillonnage sur chaque lot de matériaux entrants afin de vérifier que leur microstructure répond aux spécifications techniques. Dans un cas précis, l’analyse métallographique a mis en évidence une forte structure en bande dans un lot d’acier inoxydable, ce qui nous a permis de bloquer immédiatement ces matériaux avant leur entrée en production et d’éviter ainsi des pertes beaucoup plus importantes en aval.

Validation et optimisation des traitements thermiques

La qualité des traitements thermiques ne peut être confirmée de façon fiable qu’au niveau microstructural. Par exemple, en observant la finesse de la martensite après trempe et la distribution des carbures après revenu, nous pouvons évaluer précisément l’adéquation des paramètres de procédé. Pour les composants soumis à la nitruration, nous mesurons métallographiquement l’épaisseur de la couche blanche et de la zone de diffusion afin de garantir que la dureté de surface répond aux exigences de conception.

Évaluation de la qualité des soudures : analyse de la ligne de fusion et de la zone affectée thermiquement

Les joints soudés sont souvent le maillon le plus faible d’un assemblage. Grâce à l’analyse métallographique, nous évaluons de manière exhaustive la qualité des soudures, y compris la structure du métal fondu, la croissance de grain dans la zone affectée thermiquement et la présence éventuelle de microfissures, de manque de fusion ou d’autres défauts. Pour les surfaces traitées par usinage par électroérosion (EDM), nous caractérisons la couche de refusion et la profondeur de la zone affectée thermiquement afin de guider les opérations de finition ultérieures.

Analyse de défaillance : remonter à l’origine de la fatigue, de la corrosion et des défauts matériaux

Lorsqu’une défaillance prématurée survient, l’analyse métallographique est un outil clé pour en rechercher la cause racine. En suivant le chemin de propagation des fissures de fatigue, nous pouvons localiser le point d’amorçage. En examinant la microstructure des zones corrodées, nous identifions les mécanismes de corrosion. En observant les anomalies près des surfaces de rupture, nous détectons d’éventuels défauts matériaux inhérents. Ces informations fournissent des orientations claires pour l’optimisation de la conception et l’amélioration des procédés.

Laboratoire de métallographie Neway : équipements, processus et expertise d’ingénierie

Le laboratoire de métallographie de Neway fonctionne dans le cadre d’un système complet d’analyse qualité. De la réception des échantillons à la délivrance du rapport final, chaque étape suit des procédures opératoires normalisées strictes. Nous utilisons des équipements de meulage et de polissage entièrement automatisés pour garantir une préparation constante, et nous disposons de microscopes métallographiques avancés équipés de systèmes EDS, ce qui nous permet de réaliser à la fois l’observation structurale et l’analyse de composition sur micro-zones.

Notre équipe d’ingénieurs matériaux possède une vaste expérience pratique et maîtrise l’art de relier les caractéristiques microstructurales aux conditions réelles de service. Nous sommes ainsi en mesure de fournir des interprétations et des recommandations ayant une réelle valeur d’ingénierie. Qu’il s’agisse d’échantillons de production en petite série ou de la surveillance qualité en production de masse, nous offrons un support analytique précis et réactif.

Plus important encore, nous intégrons l’analyse métallographique dans notre système de service tout-en-un, en travaillant en étroite collaboration avec des procédés tels que le rectifiage CNC afin de réaliser un contrôle qualité couvrant l’ensemble de la chaîne de fabrication. Lorsque des microstructures anormales sont identifiées, nous ne nous contentons pas de signaler le problème : nous proposons des mesures d’amélioration ciblées, à la fois du point de vue matériau et procédé, afin d’aider les clients à améliorer fondamentalement la qualité de leurs produits.

Études de cas : comment l’analyse métallographique résout de vrais problèmes d’ingénierie

Cas 1 : défaillance prématurée de pignons de boîte de vitesses automobile

Un important constructeur automobile a signalé des piqûres précoces sur une série de pignons de boîte de vitesses. L’analyse métallographique a révélé une couche blanche et des microfissures sous les surfaces des dents endommagées, confirmant un brûlage de rectification comme cause racine de la défaillance. Sur la base de ces résultats, nous avons optimisé les conditions de refroidissement dans le processus de rectifiage, ce qui a permis de résoudre complètement le problème.

Cas 2 : évaluation de l’interface de revêtement sur des aubes de turbine aéronautiques

Pour un projet d’aubes de turbine d’un client du secteur aéronautique, l’analyse métallographique a été utilisée pour évaluer l’interface entre la barrière thermique et le substrat. Dans certaines zones, une couche d’oxydes excessive a été détectée à l’interface. En ajustant les paramètres de projection, nous avons obtenu une interface propre avec un excellent ancrage mécanique, améliorant significativement la durabilité du revêtement.

Cas 3 : détection d’inclusions dans les matières premières d’implants médicaux

Dans le secteur des dispositifs médicaux, l’examen métallographique d’un lot de matières premières destinées à des implants orthopédiques a révélé des inclusions non métalliques dépassant les limites de spécification. Ces inclusions pouvaient agir comme sites d’amorçage de corrosion ou de fissuration dans le corps humain. Nous avons immédiatement rejeté ce lot, garantissant la biocompatibilité à long terme et la sécurité des implants finis.

Au-delà du contrôle qualité : prédire les performances en service grâce aux données métallographiques

La valeur de l’analyse métallographique va bien au-delà de la simple investigation des problèmes de qualité existants. Plus important encore, elle permet de prédire les performances des produits. En établissant des corrélations quantitatives entre les caractéristiques microstructurales et les propriétés macroscopiques, nous pouvons utiliser les données métallographiques pour estimer la durée de vie en fatigue, la résistance à la corrosion et la stabilité à haute température.

Par exemple, les statistiques de taille de grain aident à prédire la résistance et la ténacité ; la quantité et la distribution des phases de durcissement permettent d’estimer le comportement à haute température ; le type et la morphologie des inclusions non métalliques donnent un aperçu des limites de fatigue. Cette capacité de prédiction du micro vers le macro nous permet d’évaluer les performances à long terme avant même que les pièces ne soient mises en service, offrant ainsi une base scientifique pour l’optimisation de la conception et l’évaluation de la durée de vie des composants critiques.

Chez Neway, nous intégrons l’analyse métallographique dans l’ensemble du cycle de développement produit et du contrôle qualité, en accumulant et en interprétant en continu les données pour affiner nos technologies de usinage de précision. Cela nous permet de fournir à nos clients des composants offrant des performances supérieures et une durée de service accrue.