X-ray Inspection Workshop for Internal Defect Detection in CNC Parts

Revealing the Invisible World: Why X-ray Inspection Is Indispensable

In precision manufacturing, the integrity of part quality directly determines final product performance and reliability. As quality engineers at Neway, we recognize that many potential defects are concealed within parts and cannot be reliably detected by visual inspection or conventional methods. This is exactly where industrial X-ray inspection demonstrates its irreplaceable value. Through this advanced non-destructive testing technology, we can “see through” parts as if equipped with an all-seeing eye, ensuring every delivered component meets the highest quality standards.

As modern industries place ever-growing demands on component reliability—particularly in aerospace, medical devices, and automotive manufacturing—tiny internal pores, cracks, or inclusions can trigger severe consequences. Our precision machining services consistently prioritize quality, and X-ray inspection is a vital component of our quality assurance system.

The Core of X-ray Testing Technology: From 2D Radiography to 3D Industrial CT

2D Real-time Imaging: Rapid Screening and Positioning

2D X-ray inspection is a fundamental and highly efficient screening method. By placing the part between the X-ray source and the detector, we obtain a two-dimensional projection image of its internal structure. This approach is particularly suitable for rapid screening and preliminary defect localization in mass production. In our inspection workshop, 2D X-ray is typically used as the first gate to quickly identify parts with obvious defects, saving valuable time for subsequent, more detailed inspections.

3D Computed Tomography (CT): Three-dimensional Quantitative Defect Analysis

Industrial CT represents the state-of-the-art in non-destructive testing. By capturing hundreds or even thousands of 2D projection images from multiple angles and reconstructing them via computer algorithms, we obtain a three-dimensional model of the part. This technology not only accurately reveals the spatial location of defects, but also quantifies their size, volume, and relationship to surrounding structures. For parts with complex internal geometries, CT inspection provides unprecedented insight.

Which CNC Parts Must Receive X-ray “Health Checks”?

Components with Complex Internal Channels or Cavities

Complex parts manufactured using multi-axis machining services, such as engine fuel nozzles and hydraulic valve blocks, often feature intricate internal passages and cavities. During machining, defects such as burr residues, broken drill tips, or blocked channels may occur. Only X-ray inspection can effectively verify internal connectivity and structural integrity.

Lightweight Yet High-Strength Aerospace and Automotive Components

In aerospace and automotive applications, lightweight components manufactured via aluminum alloy machining and titanium alloy machining must maintain sufficient strength despite reduced weight. Any internal defect can become a potential source of failure. X-ray inspection reliably detects metallurgical defects and machining-induced damage inside these materials.

Safety-Critical Medical Implants and Instruments

In the medical device manufacturing sector, the internal quality of orthopedic implants and surgical instruments is directly linked to patient safety. We use X-ray inspection to ensure these products are free from dangerous internal defects and fully compliant with the stringent standards of the medical industry.

Complex Structures Produced by Additive Manufacturing

With the widespread adoption of 3D printing, it has become feasible to manufacture parts with complex internal lattice structures. However, additive manufacturing processes are prone to typical defects such as lack of fusion and porosity. X-ray inspection, particularly industrial CT, has become crucial for verifying the internal quality of these components.

Inside Neway’s X-ray Testing Workshop: Our Equipment and Processes

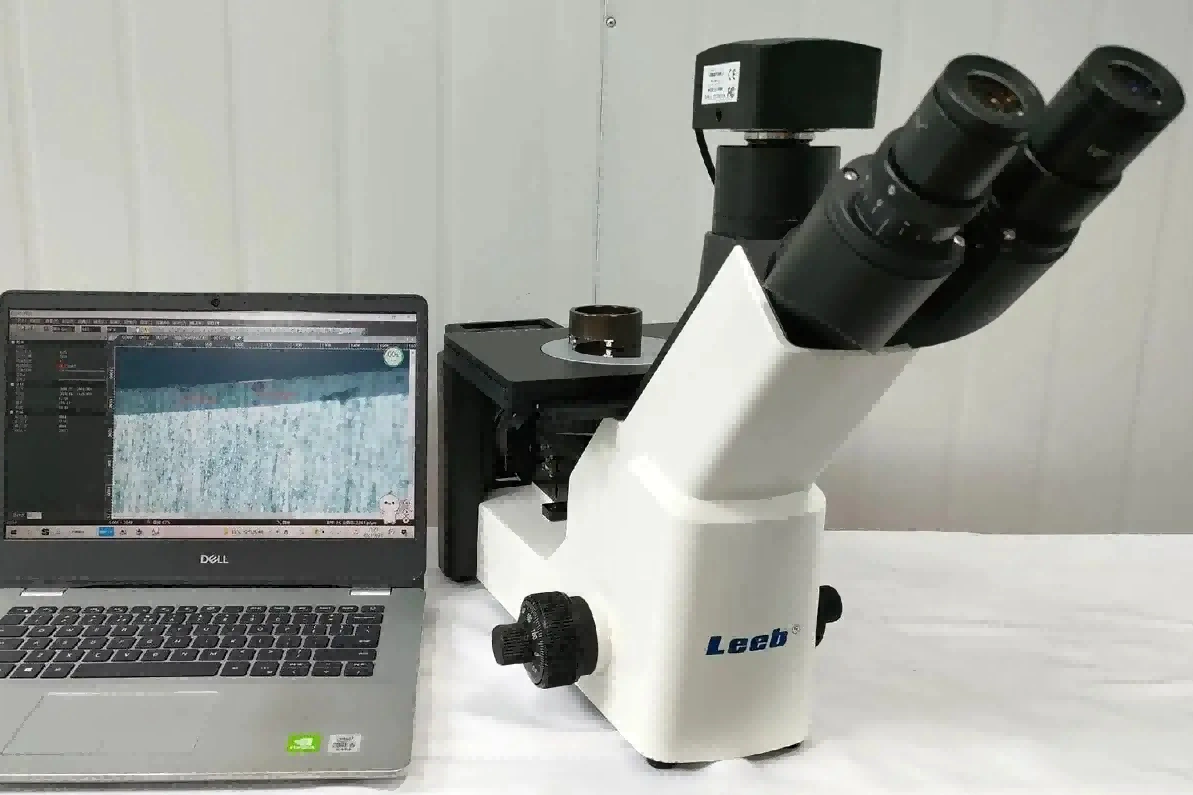

Introduction to High-Precision X-ray Inspection Systems

Neway’s X-ray testing workshop is equipped with industry-leading systems, including high-resolution micro-focus X-ray sources, flat-panel detectors, and six-axis robotic manipulators. Our systems achieve inspection resolutions of 1 micron, covering a full range of applications, from large structural components to miniature electronic parts. The wide adjustment range of voltage and current allows us to optimize inspection parameters for different materials and wall thicknesses.

Standardized Five-Step Testing Process

We have established a rigorous process: first, sample registration and confirmation of inspection requirements; second, defining the inspection scheme based on material and structural characteristics; third, parameter optimization and image acquisition; fourth, detailed image analysis and defect evaluation; and finally, issuance of an authoritative inspection report. This standardized workflow ensures consistent and reliable results for every part inspected.

From Data Acquisition to 3D Model Reconstruction

For industrial CT inspections, we use advanced iterative reconstruction algorithms to convert 2D projection data into high-quality 3D volumetric datasets. With professional analysis software, we can arbitrarily section the part in three-dimensional space, precisely measure internal features and their positions, and even directly compare them against CAD models.

Accurate Identification: Typical Internal Defect Atlas Under X-ray

Porosity and Shrinkage Voids

In cast aluminum alloy ADC12 components, porosity and shrinkage are the most common casting defects. On X-ray images, pores typically appear as round or elliptical dark areas with smooth edges, while shrinkage cavities exhibit dendritic or sponge-like dark regions. These defects significantly reduce mechanical performance, especially under fatigue loading.

Cracks and Lack of Fusion

For high-temperature alloys such as Inconel 718, micro-cracks may form during welding or heat treatment. On X-ray images, cracks appear as slender dark lines, while a lack of fusion shows up as distinct interfaces between materials. These discontinuities act as stress concentrators and can easily propagate during service, leading to part failure.

Inclusions and Density Variations

Non-metallic inclusions in metals, or foreign particles mixed into components during plastic machining, exhibit different densities from the base material and hence different grayscale levels in X-ray images. High-density inclusions appear as bright spots, while low-density inclusions appear as dark spots. Through comparative analysis, we can accurately identify these anomalies and assess their impact.

Foreign Objects and Missing Parts Inside Assemblies

For complex assemblies, X-ray inspection enables the verification of internal conditions without disassembly, allowing for the detection of foreign objects or missing components. For example, in automotive electronic control units, we can clearly observe the quality of solder joints, component positioning, and whether any fasteners are missing.

Beyond Inspection: Closed-Loop Application of X-ray Data in Design and Manufacturing

Providing Irrefutable Evidence for Design Validation

During the prototyping stage, X-ray and CT data offer direct evidence for design validation. By comparing CT scan results with the original CAD model, engineers can accurately evaluate deviations between actual parts and design intent, providing a solid basis for design optimization.

Guiding Process Optimization

X-ray inspection results are closely linked to manufacturing process parameters. When characteristic defect patterns are observed, we can trace them back to specific process steps. For example, analyzing crack distributions in parts after heat treatment helps optimize heat treatment cycles, while studying pore locations in PEEK injection-molded parts enables us to refine injection parameters.

Enabling Precise Failure Analysis

When parts fail in service, X-ray inspection is a key tool in failure analysis. By comparing failed and intact parts, we can determine the origin and propagation path of the failure, identify the root cause, and propose effective corrective measures.

Five Key Reasons to Choose Neway’s X-ray Testing Workshop

At Neway, we regard X-ray inspection as a core element of our quality assurance framework, rather than an isolated testing service. Our strength lies in the deep integration of inspection technologies with manufacturing processes. As manufacturing experts, we not only detect defects but also understand their formation mechanisms, enabling us to provide solutions that address issues at their source.

Our inspection team comprises senior engineers and technicians with multiple professional certifications and extensive knowledge of industry standards. Whether it is sample validation for low-volume production or statistical process control for mass production, we deliver tailored inspection strategies.

Most importantly, we adhere to a one-stop service philosophy, seamlessly integrating X-ray inspection into the entire manufacturing workflow. From raw material verification and in-process monitoring to final product inspection, X-ray data play a vital role throughout the product lifecycle, helping customers continuously improve product quality and reliability.

Frequently Asked Questions (FAQ)

What are the main differences between X-ray inspection and ultrasonic testing?

What level of accuracy and resolution can industrial CT scanning achieve?

Does the inspection process affect my part materials, will it cause degradation in plastics?

Can Neway provide inspection reports that comply with specific standards?

What is the typical turnaround time from submitting parts for inspection?