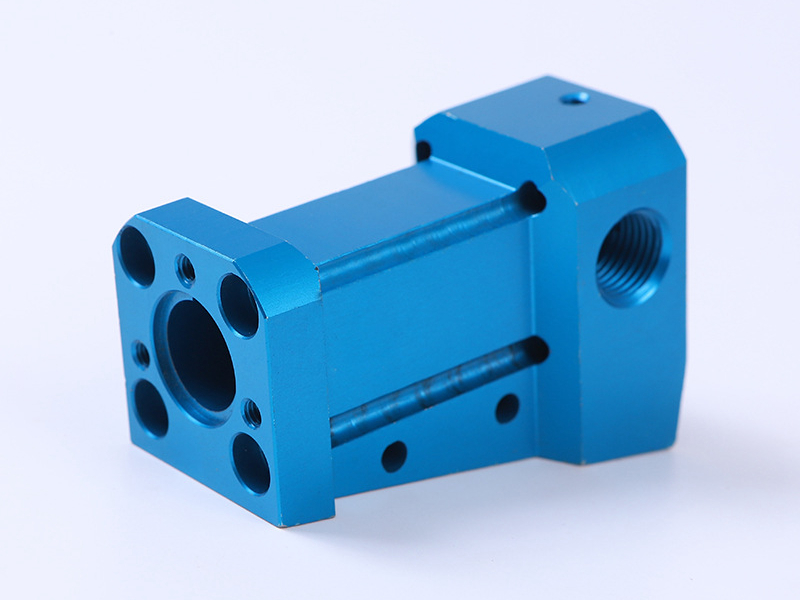

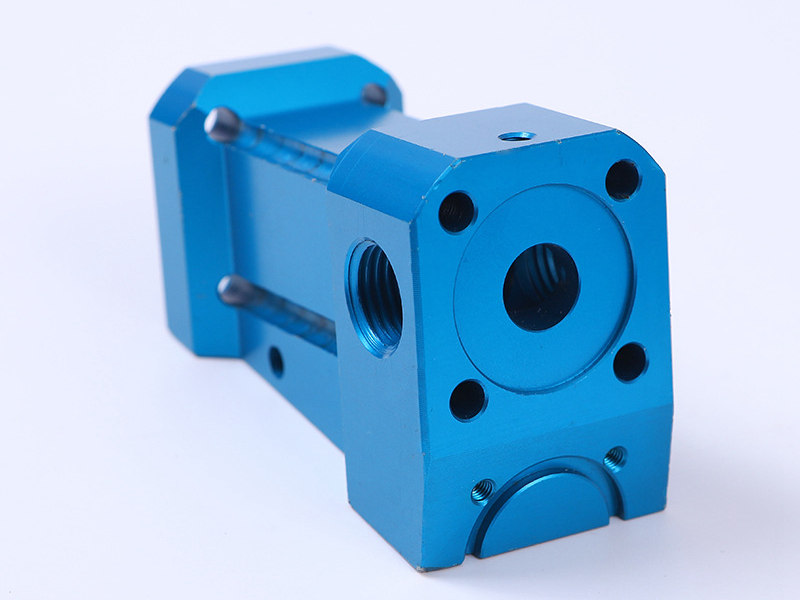

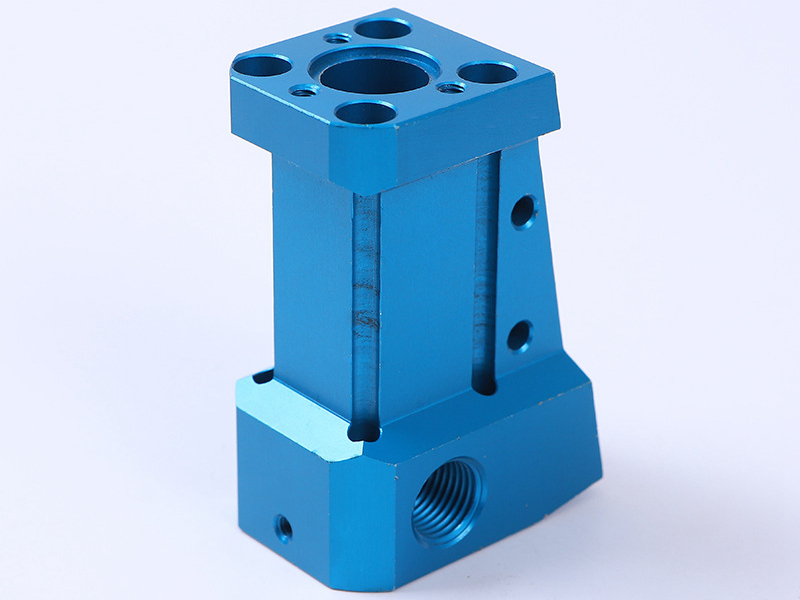

Multi-Axis CNC Machining and Anodizing for Aluminum 6063 Appliance Mounting Brackets

CNC Machining of Appliance Mounting Brackets: Lightweight and Durable Solutions for Consumer Products

Mounting brackets used in home appliances must offer precise dimensional control, excellent aesthetics, and reliable strength. These components play a key role in assembly alignment, vibration damping, and structural integrity across consumer electronic housings, panels, and control interfaces. Neway offers multi-axis CNC machining and CNC drilling of Aluminum 6063 to produce high-accuracy bracket components for consumer appliances.

Each part is finished with sandblasting and anodizing to deliver corrosion protection, color uniformity, and a refined surface appearance that matches modern appliance design standards.

Why Aluminum 6063 Is Ideal for Appliance Bracket Manufacturing

Superior Extrudability and Surface Finish

Aluminum 6063 is optimized for surface-critical applications. With excellent anodizing response and moderate strength (~190 MPa), it is widely used for structural and cosmetic components in domestic electronics and white goods.

Lightweight and Cost-Effective

Its low density and smooth machining behavior allow fast cycle times and reduced component weight—critical for wall-mounted, embedded, or portable appliance modules.

CNC Machining Workflow for Consumer Appliance Brackets

Multi-Axis Machining for Form and Fixture Integration

Complex bracket geometries are milled using 4- and 5-axis machining systems to eliminate multiple setups. This ensures:

±0.01 mm tolerance on mounting hole positions

Parallel and perpendicular surfaces for housing alignment

Custom geometry adaptation for tight assembly envelopes

CNC Drilling for Fastener and Alignment Points

All holes for bolts, clips, or dowels are finished using CNC drilling with precise depth and diameter control, ensuring:

Thread-ready bores with M3–M6 size range

Countersinks and spot faces for flush fittings

Clean edge definition and burr-free exits

Surface Finishing: Sandblasting and Anodizing

Sandblasting for Texture Uniformity

Sandblasting removes minor machining marks and creates a matte surface ideal for consistent anodizing. It also improves grip and visual appeal on exposed consumer surfaces.

Anodizing for Aesthetic and Corrosion Protection

Anodizing enhances corrosion resistance while providing visual consistency for mass-market product integration. Key specifications:

Thickness: 10–15 µm for standard Type II

Color options: clear, silver-gray, black, or custom tones

Scratch-resistant surface for repeated handling

Quality Control and Inspection

Coordinate measurement of hole positions and flatness

Surface uniformity checks after blasting and anodizing

Anodizing adhesion and thickness testing

Certificates: COC, RoHS, REACH, anodizing batch records

Why Choose Neway for Appliance Mounting Bracket Manufacturing

Experience in Aluminum 6063 CNC machining for aesthetic and structural components

Integrated sandblasting and anodizing services for cosmetic finish control

Low- to mid-volume production for consumer product brands

One-stop CNC service from prototyping to packaging

CNC Services for Consumer Appliance Bracket Projects

Neway delivers end-to-end manufacturing solutions for aluminum appliance components. Our capabilities include:

Multi-Axis CNC Machining: For intricate bracket geometry and structural precision

CNC Drilling: For mounting points, fastener holes, and alignment features

Surface Finishing: Blasted and anodized surfaces for commercial-grade durability

We help appliance OEMs reduce time to market with scalable, high-accuracy machining solutions that meet both technical and aesthetic demands.

FAQs

What anodizing options are available for aluminum appliance brackets?

What tolerances can you maintain on multi-axis machined aluminum parts?

Can Neway provide clear or colored anodizing for product line differentiation?

How do you ensure burr-free holes and accurate drilling positions?

What production volumes can Neway support for home appliance parts?