CNC Machining of Inconel 738 LC Jet Engine Turbo Components for KBB Turbo

Project Background: High-Temperature Turbine Components for Aerospace Jet Engines

KBB Turbo, a leading supplier of advanced turbo systems for aerospace propulsion, required a thermally stable and fatigue-resistant turbine component for use in high-speed jet engine assemblies. The part had to withstand extreme heat, oxidation, and mechanical stress over prolonged operating cycles. Neway was selected to machine this critical aerospace-grade component from Inconel 738 LC superalloy.

Why Inconel 738 LC Was Selected for Jet Engine Turbos

Inconel 738 LC offers superior creep resistance, fatigue strength, and oxidation stability at elevated temperatures, making it one of the most widely used materials in turbine hot sections.

Property | Value |

|---|---|

Operating Temperature | Up to 980°C |

Yield Strength | ≥800 MPa |

Creep Rupture Life | Excellent (1000+ hrs at 870°C) |

Machinability | Low – Requires carbide and ceramic tooling |

Learn more about Inconel 738 LC CNC Machining and why it’s ideal for aerospace thermal-critical applications.

Multi-Step CNC Machining Process

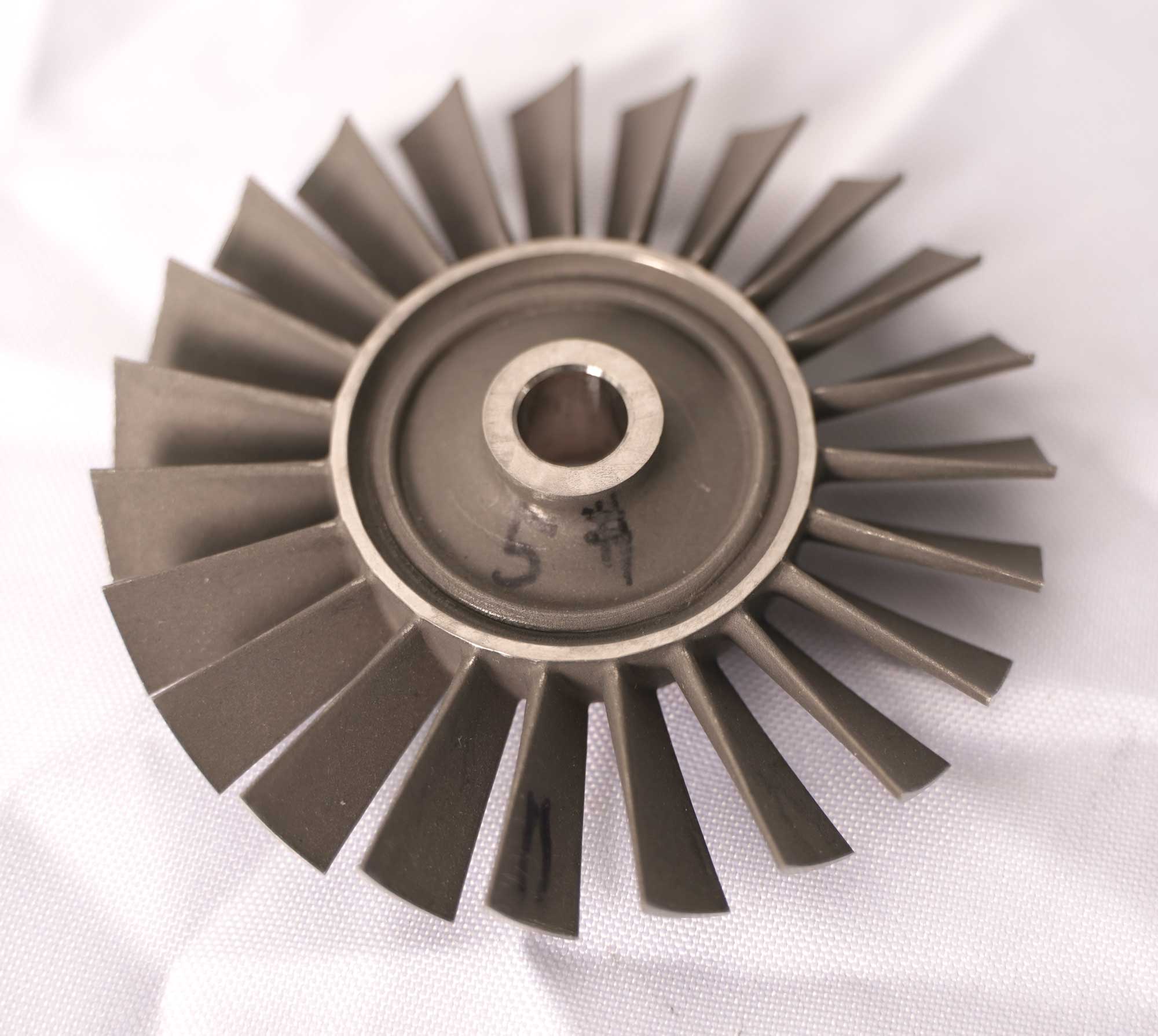

CNC Turning

Initial stock removal and concentric feature formation were performed on a high-torque CNC turning center. Surface speeds were optimized below 30 m/min with ceramic inserts to reduce work hardening during profiling.

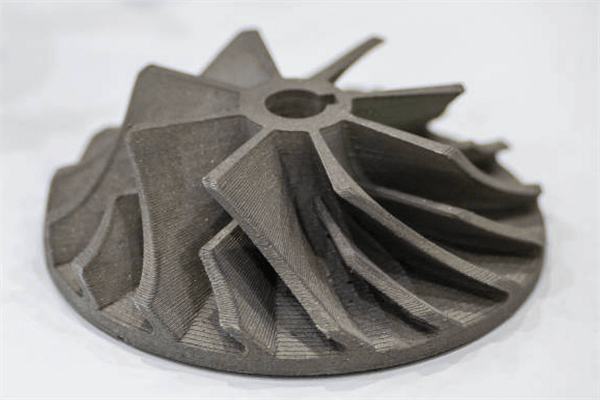

5-Axis CNC Precision Machining

Aerodynamic channels, contour blades, and hub geometry were completed in a single clamping setup using 5-axis CNC machining. True position tolerances were held within ±0.01 mm, and blending between axial and radial profiles was performed with high-speed interpolation control.

CNC Drilling

High-precision cooling holes and oil flow channels were produced with CNC drilling, applying peck drilling cycles and through-coolant carbide drills to manage tool wear in this tough superalloy.

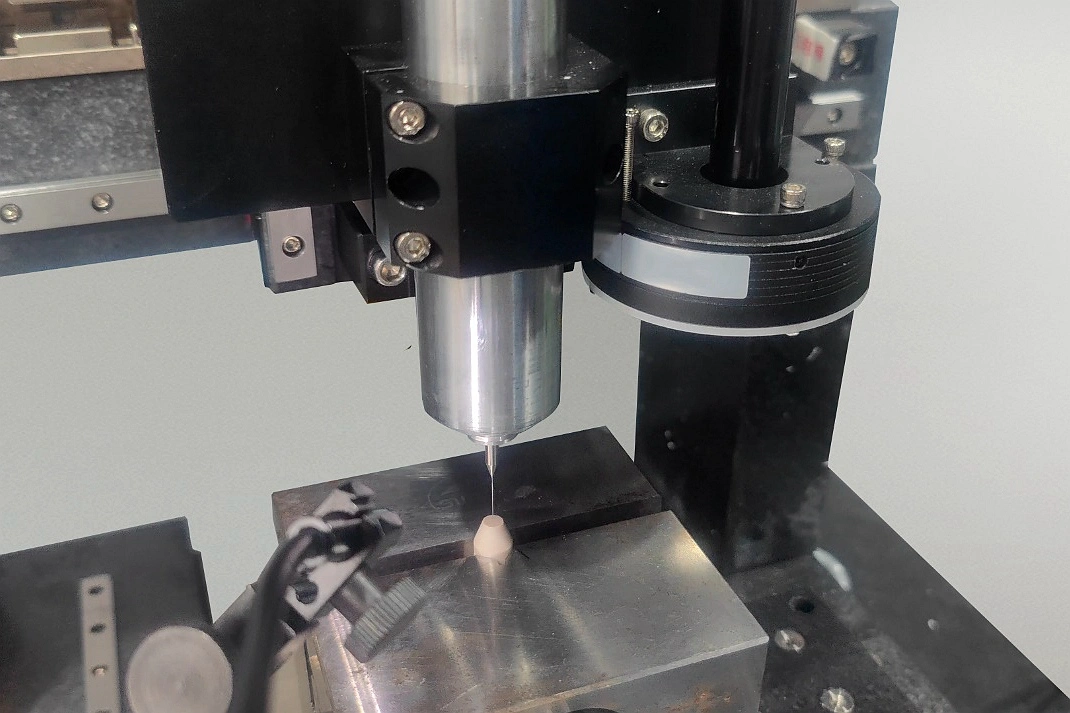

CNC Grinding

Critical sealing surfaces and journal bearing diameters were finished using CNC grinding. Surface finish achieved was Ra ≤ 0.4 μm, essential for tight clearances in high-speed rotating assemblies.

Quality Assurance and Final Validation

CMM Metrology: All aerodynamic and sealing profiles were inspected using 5-axis coordinate metrology systems

Surface Roughness Verification: Ground regions verified using profilometers calibrated to ISO 4287

Hole Integrity Test: All cooling holes tested for diameter, angle, and flow using air-leak and borescope systems

Project Outcome

Neway delivered a batch of 800 units to KBB Turbo’s jet engine division. Each part passed high-temperature stress and vibration testing. Machining accuracy enabled zero rework during final engine assembly. KBB recognized Neway’s performance in handling complex superalloy components and maintaining batch-to-batch consistency.

Why Neway for Inconel Jet Engine Machined Components

Superalloy CNC Machining: Decades of experience machining nickel-based superalloys with specialized tooling and process control

CNC Grinding Service: Ultra-fine finishing for rotor and sealing surfaces in high-speed jet systems

One-Stop Aerospace CNC Service: Full vertical integration of roughing, finishing, and QA inspection for critical flight components

FAQs

What is the recommended machining strategy for Inconel 738 LC to avoid thermal distortion?

How does CNC grinding improve sealing performance in jet engine components?

What tooling and speeds are optimal for drilling cooling holes in superalloys?

How is dimensional stability maintained during multi-process superalloy machining?

What inspection methods ensure precision in 5-axis machined aero parts?