Precision 5-Axis CNC Machining for Olympus TG4 Camera Housing in Aluminum 6063

Project Background: High-Performance Housing for Optical Equipment

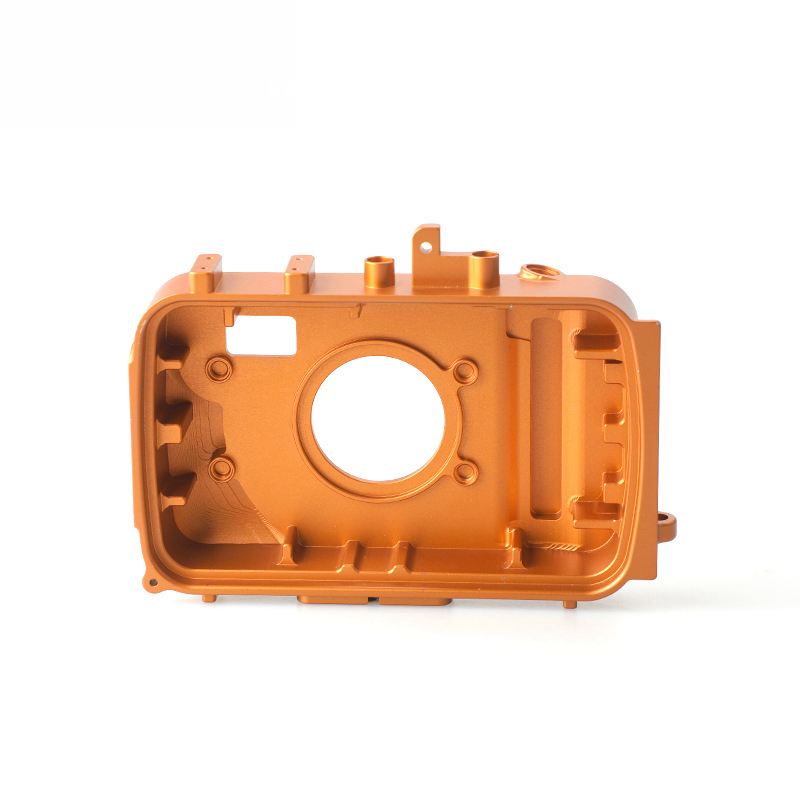

Olympus required a lightweight yet structurally robust outer shell for its TG4 series—a rugged, waterproof digital camera known for surviving harsh outdoor environments. Neway was selected as the CNC machining partner to deliver this aluminum housing through a highly coordinated, multi-step manufacturing workflow that balanced tight tolerances with premium aesthetics.

Why Aluminum 6063 Was Selected

Aluminum 6063 was chosen for its outstanding balance of strength, corrosion resistance, and surface treatment compatibility. Commonly used in architectural and consumer-grade electronics, this alloy features:

Property | Value |

|---|---|

Tensile Strength | ≥190 MPa |

Elongation | ≥8% |

Density | 2.7 g/cm³ |

Surface Finish Suitability | Excellent for anodizing and sandblasting |

Its excellent response to anodizing and dimensional stability under high-precision machining make it ideal for TG4 housings. Learn more about Aluminum 6063 CNC Machining.

Process Workflow: Combining Efficiency and Precision

3-Axis CNC Rough Milling

Initial rough machining was performed using 3-axis CNC milling to efficiently remove excess material and establish base geometry, preserving critical allowance for fine detailing.

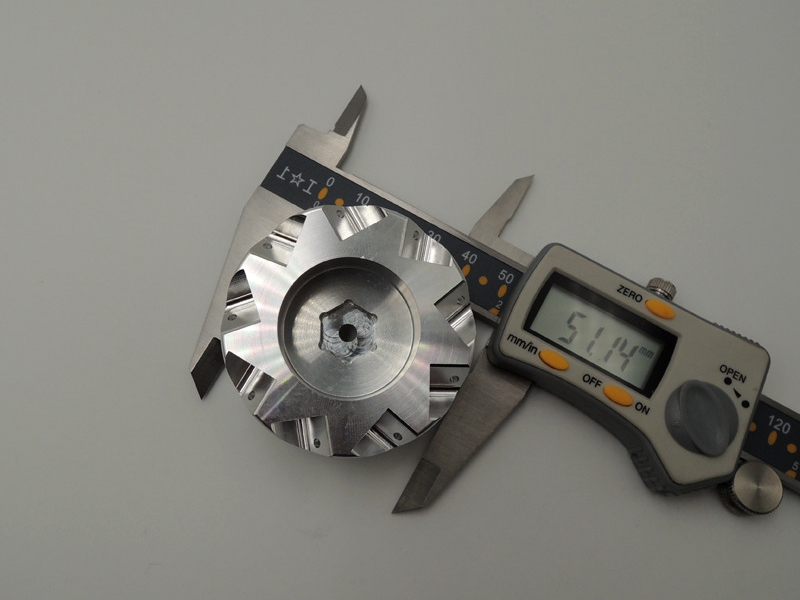

5-Axis CNC Precision Machining

The housing’s intricate geometries—recessed contours, tight radii, and undercuts—were completed using 5-axis CNC milling. This enabled multi-directional tool access with precision held to ±0.01 mm, eliminating repositioning errors and improving throughput.

Surface Finishing Sequence

To achieve Olympus’ premium consumer aesthetic, a series of surface treatment steps were applied:

Sandblasting – Provided a uniform matte texture at ~Ra 1.6 μm.

Anodizing – Improved corrosion resistance and color consistency (10–15 μm thickness).

Laser Marking – Applied brand logo and part ID with high contrast and permanent fidelity.

Quality Assurance & Inspection

Dimensional Inspection: All critical features were verified using a CMM with ±2 μm repeatability.

Surface Quality Control: Post-anodizing thickness was checked with eddy current gauges.

Cosmetic Inspection: All visible surfaces passed ISO 1302 surface finish standards and Olympus’s aesthetic grading.

Result & Client Feedback

Neway delivered over 500 high-precision TG4 housings in the initial production run. Olympus confirmed that the components met all functional and cosmetic benchmarks without requiring secondary adjustments. The blend of advanced machining and integrated surface treatment led to reduced cycle time and superior visual consistency across batches.

Why Neway for Complex CNC Camera Housing Projects

Aluminum CNC Machining: Our advanced multi-axis machining capabilities allow for efficient production of complex geometries, ensuring accuracy on every face and curvature.

Precision Machining Service: We hold tolerances down to ±0.005 mm, delivering repeatable accuracy required for tight-assembly parts like camera housings.

One-Stop Manufacturing Service: From initial 3-axis roughing to final anodizing and laser marking, we offer fully integrated machining and finishing under one roof for streamlined delivery.

FAQs

What are the key dimensional tolerances achievable with 5-axis CNC machining for camera housings?

How does Aluminum 6063 compare to 6061 in CNC machining performance and finish quality?

What surface roughness can be achieved after sandblasting and anodizing?

Can Neway provide full cosmetic inspection reports for consumer electronics applications?

How is laser marking applied after anodizing without damaging the finish?