What are the main cost drivers in ceramic CNC machining projects?

Material Acquisition and Pre-Processing Expenses

The initial and often significant cost driver is the raw material itself. Advanced technical ceramics, such as zirconia and Alumina, are inherently expensive to manufacture due to the high-purity powders and complex sintering processes required. Furthermore, these materials are typically supplied in blanks or pre-sintered forms that require precise machining to achieve the desired starting geometry for final machining, adding to the pre-processing cost. The hardness and wear resistance that make ceramics valuable also make them consumptive on tooling, directly impacting project economics.

Machining Time and Complex Part Geometry

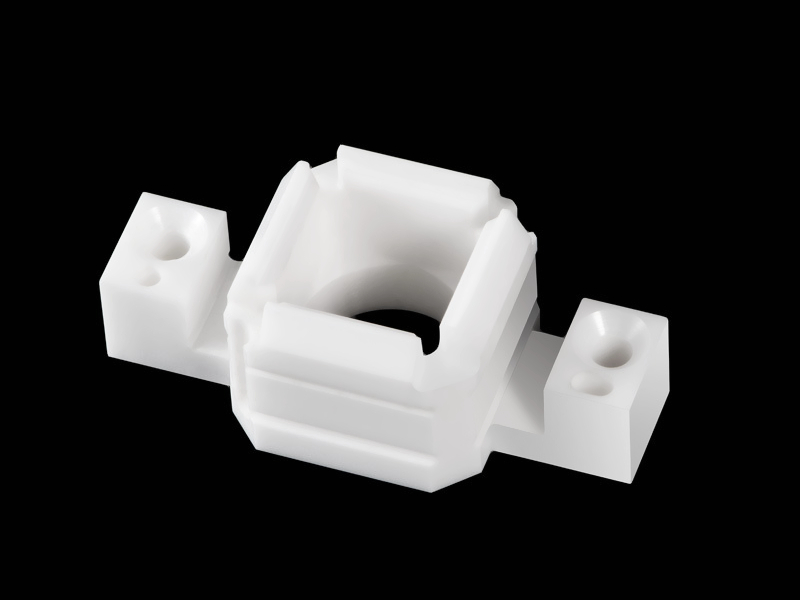

Machining time is a direct function of part complexity and material removability. Ceramics cannot be machined as aggressively as metals; they require lower feed rates and depths of cut to prevent chipping and cracking. Consequently, even simple geometries require more time to produce. Complex features, such as thin walls, deep holes, or intricate contours, exponentially increase machining time. Producing such features often necessitates advanced Multi-Axis Machining Services to minimize setups and specialized CNC grinding services with diamond-impregnated tools, both of which are cost-intensive processes.

Tooling Wear and Specialized Equipment

The extreme hardness of ceramics results in rapid tool wear. Diamond-plated grinding wheels and PCD (Polycrystalline Diamond) cutting tools are mandatory; however, their high cost and limited lifespan are significant cost contributors. This machining process also requires rigid, high-precision machine tools to maintain accuracy and prevent vibrations that can cause the workpiece to fracture. The use of non-traditional methods, such as Electrical Discharge Machining (EDM), for certain conductive ceramics introduces costs associated with specialized equipment and electrode fabrication.

Dimensional Tolerances and Surface Finish Requirements

Tighter specifications directly increase cost. Holding micron-level tolerances on ceramic parts requires slower, more meticulous machining cycles and sophisticated in-process inspection. Similarly, specific surface finish requirements, such as a mirror polish for reduced friction or a matte finish for aesthetic purposes, necessitate additional post-processing steps. Techniques such as CNC Part Polishing Service or Sandblasting Process for CNC Components require additional time, labor, and expertise, thereby adding layers of cost to the base machining operation.

Quality Assurance and Secondary Operations

The brittle nature of ceramics makes quality control a paramount concern. Comprehensive inspection using CMMs (Coordinate Measuring Machines) and other metrology tools is essential to verify dimensional integrity and detect micro-cracks. This rigorous CNC Machining Prototyping level of scrutiny is a fixed cost. Additionally, components for demanding sectors like Medical Device and Aerospace and Aviation often require complete documentation and traceability, which adds administrative and testing overhead to the project cost.