How do you ensure bottom shape and dimensional accuracy for blind deep holes?

At Neway, achieving precise bottom shape and strict dimensional accuracy in blind deep holes represents one of the most challenging aspects of precision machining. This capability requires specialized tooling, advanced process controls, and extensive technical expertise. We've developed comprehensive solutions that address these challenges across various materials and applications.

Specialized Tooling Solutions for Bottom Geometry Control

The configuration of the hole bottom is primarily determined by tool selection and path planning. We employ several specialized tooling approaches to achieve the required bottom geometries.

Flat Bottom Drilling Systems

For truly flat bottoms, we utilize dedicated flat-bottom drilling tools with specially ground cutting edges that produce a clean, perpendicular surface. These tools are particularly effective in materials like Aluminum 6061 and Stainless Steel SUS303 where we can achieve surface flatness within 0.01mm across the entire bottom surface. The tool geometry includes precise relief angles and cutting edge preparation to ensure clean material separation at the center point.

Contoured Bottom Tooling

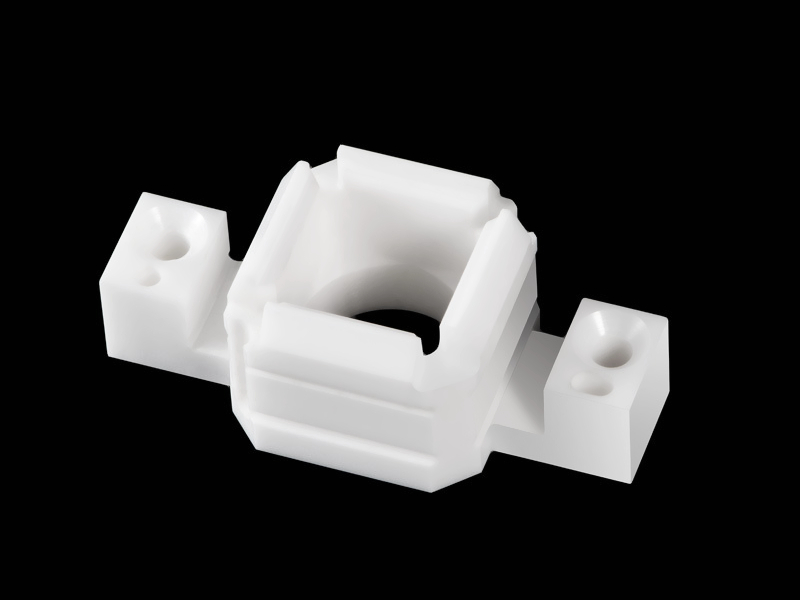

For applications requiring specific bottom contours (such as domed, conical, or custom profiles), we utilize form tools with precisely dressed cutting edges that match the required geometry. This approach is common in automotive injection systems and Medical Device components where fluid dynamics depend on specific internal contours.

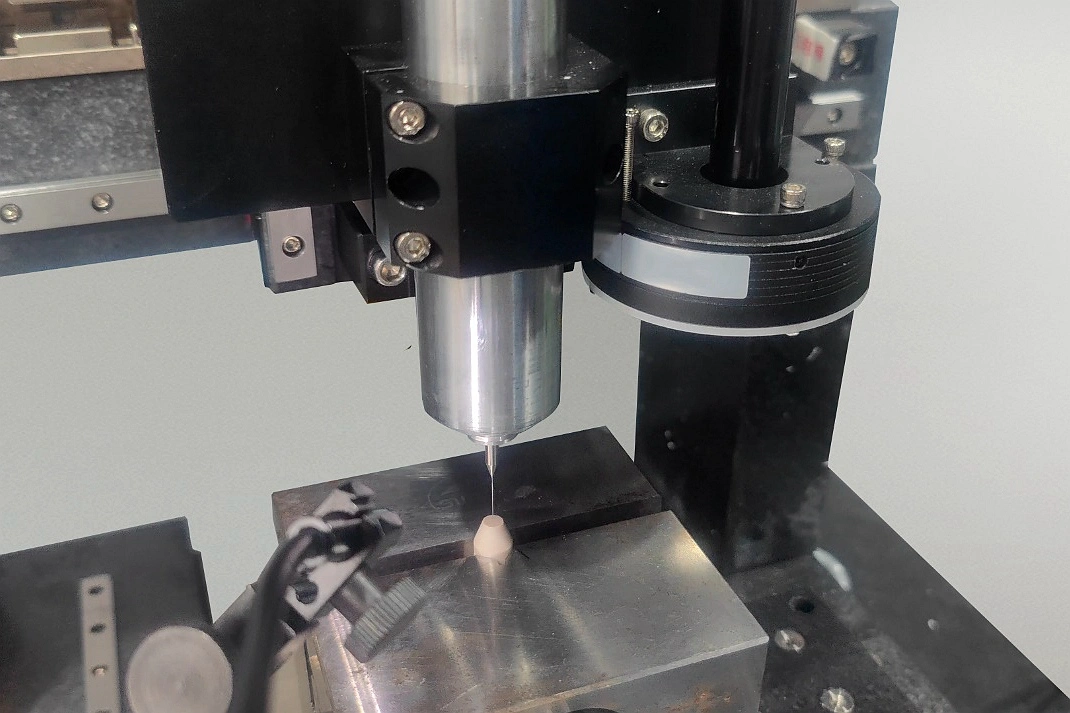

Non-Conventional Machining Integration

In certain challenging applications, particularly with hardened materials or complex geometries, we combine traditional drilling with Electrical Discharge Machining (EDM) Service to achieve precise bottom features that would be impossible with conventional cutting tools alone.

Advanced Process Controls for Dimensional Accuracy

Maintaining dimensional accuracy throughout the depth of blind holes requires addressing multiple technical challenges simultaneously.

Chip Evacuation Management

In blind holes, chip evacuation becomes increasingly critical as depth increases. We implement several strategies:

Peck drilling cycles with optimized retraction distances to break and clear chips

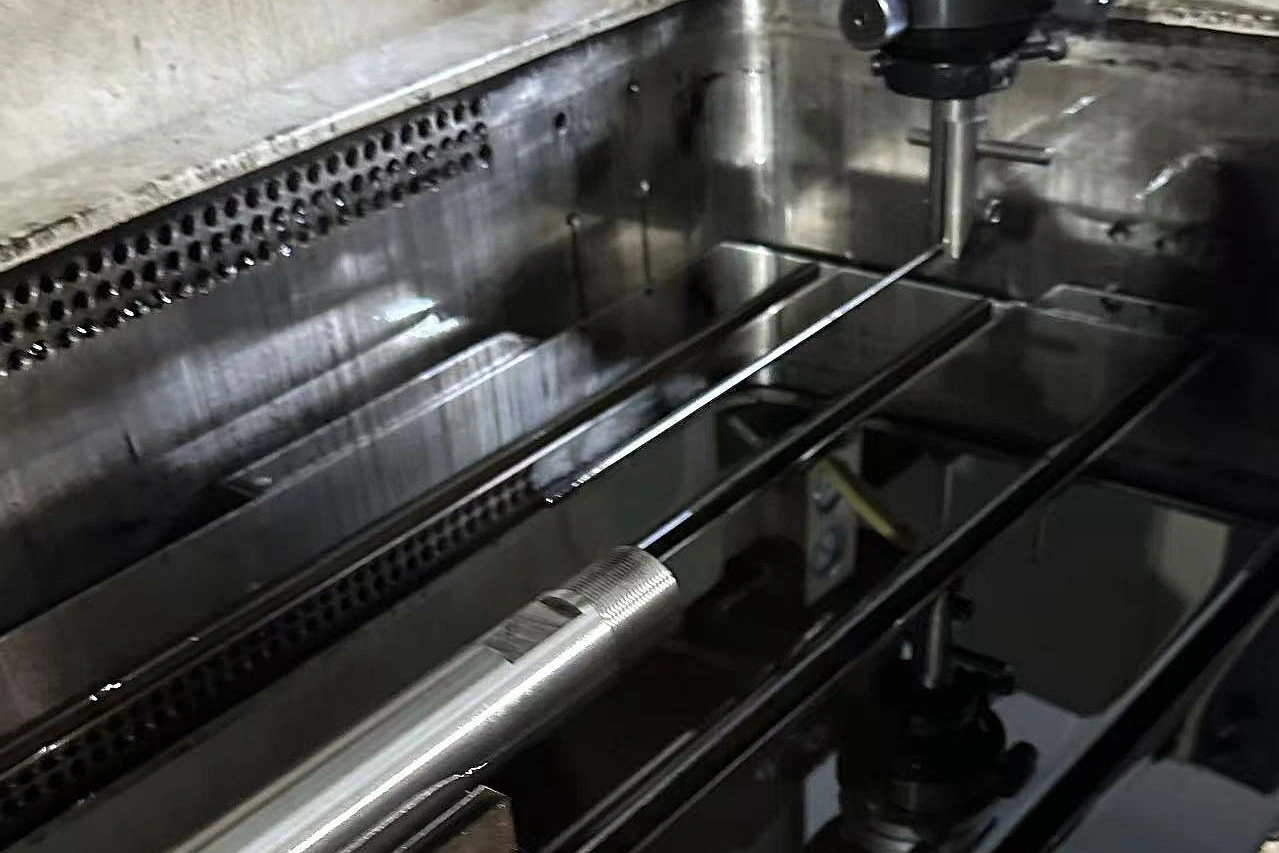

High-pressure coolant systems delivering cutting fluid through the tool to force chips out of the hole

Customized cutting parameters that produce manageable chip forms rather than long, continuous strands

Thermal Distortion Compensation

The extended cutting times and confined spaces in deep hole machining generate significant heat. Our approach includes:

Thermal modeling to predict expansion effects during machining

Coolant temperature control systems maintaining stable thermal conditions

In-process compensation based on real-time monitoring for critical dimensions

Tool Deflection Management

As drill length increases, tool deflection becomes a major factor in dimensional accuracy. We address this through:

Stiffness-optimized toolholders with minimal overhang

Progressive drilling sequences starting with shorter, stiffer tools

Active tool monitoring systems that detect deflection and adjust parameters accordingly

Precision Measurement and Verification Techniques

Verifying blind hole dimensions and bottom geometry requires specialized metrology approaches beyond standard measurement techniques.

Non-Contact Internal Inspection

We utilize advanced bore scopes and video probe systems with articulating tips to visually inspect bottom surfaces and sidewalls. These systems provide magnified views of the hole interior, allowing us to verify the integrity of the surface finish and detect any imperfections at the blind end.

Custom Gauge Development

For critical dimensions, we design and manufacture custom gauge pins with specific end features that match the required bottom contour. These gauges provide go/no-go verification of both depth and bottom shape in a single measurement.

CMM with Specialized Probes

Our coordinate measuring machines are equipped with long, slender probes with star tips that can reach deep into blind holes and map the bottom geometry through point cloud data. This approach is particularly valuable for Precision Machining Service components in Aerospace and Aviation applications where dimensional certification is required.

Material-Specific Machining Strategies

Different materials present unique challenges for blind deep hole machining, requiring tailored approaches.

Aluminum and Non-Ferrous Alloys

For materials like Aluminum 7075 and copper alloys, we focus on:

Built-up edge prevention through specialized tool coatings

Surface finish optimization with polished flute surfaces

Chip welding avoidance through parameter optimization

High-Temperature Alloys

With challenging materials such as Inconel 718 and Ti-6Al-4V (TC4), our approach includes:

Conservative cutting parameters to control workpiece hardening

Specialized tool geometries with high positive rakes

Advanced tool materials including solid carbide and PCD-tipped drills

Hardened Steels

For pre-hardened materials like 4140 Steel and tool steels, we employ:

Carbide tooling with wear-resistant coatings

Reduced cutting forces through trochoidal milling techniques

Vibration damping toolholders to minimize chatter in deep cavities

Integrated Quality Assurance Framework

Our approach to ensuring blind hole quality extends throughout the entire manufacturing process.

Pre-Process Validation

Before machining, we conduct:

Tool runout verification to ensure concentricity

Coolant pressure testing to confirm adequate flow

Program simulation to visualize the complete machining sequence

In-Process Monitoring

During machining, we implement:

Torque monitoring to detect tool wear before it affects part quality

Acoustic emission sensors to identify chip packing or other anomalies

Adaptive control systems that adjust feed rates based on actual cutting conditions

Post-Process Verification

After machining, we perform:

Destructive analysis on first article components to validate internal features

Statistical process control tracking of critical dimensions

Surface roughness measurement at the hole bottom using replica techniques

This comprehensive approach ensures that blind deep holes meet the most stringent requirements for bottom shape and dimensional accuracy, supporting critical applications across Automotive, Power Generation, and industrial sectors.