High-Precision 5-Axis CNC Machining for Sony Aluminum 6061 Optical Lens Housing

Project Background: Structural Shell for High-End Optical Lens

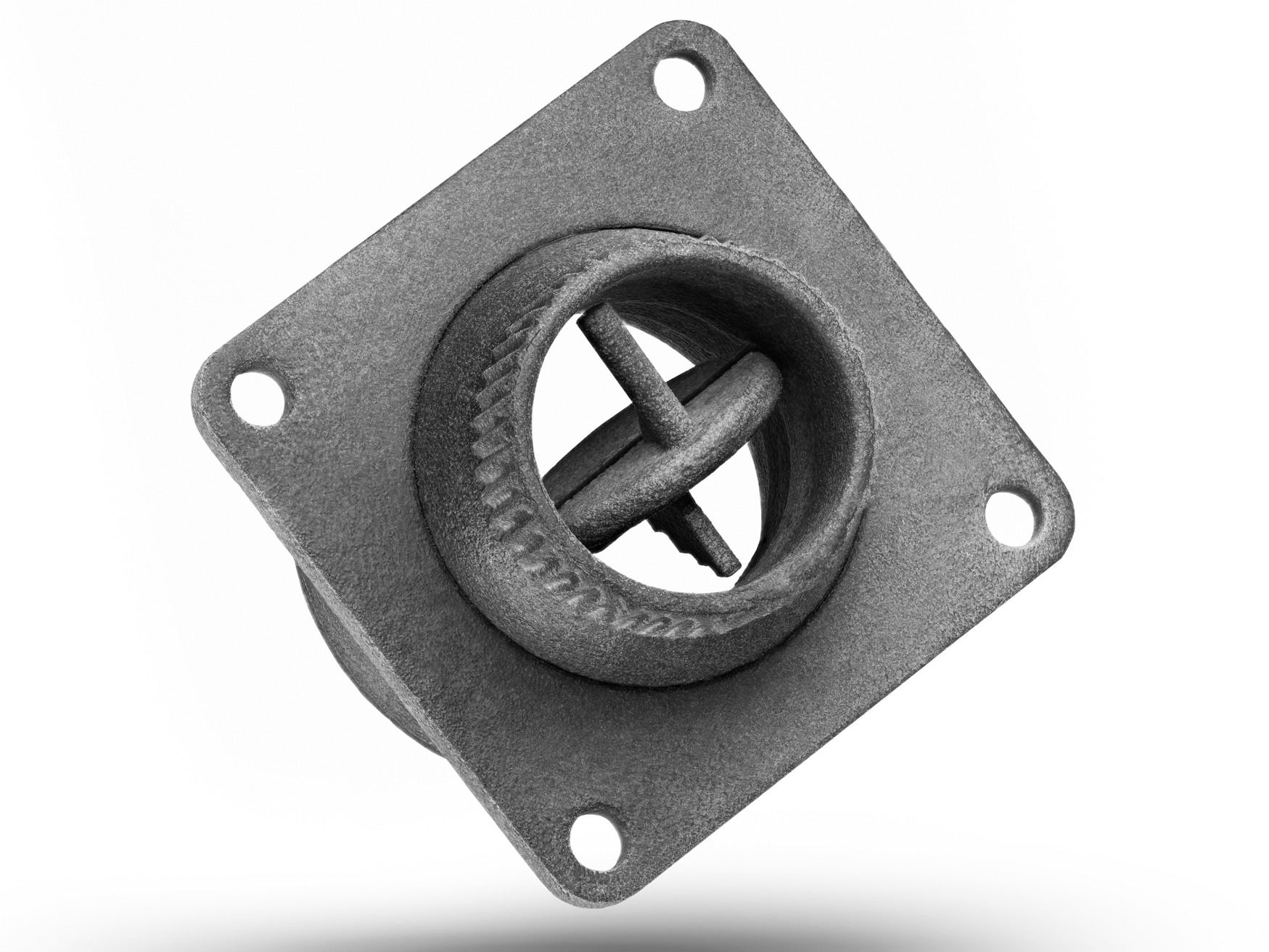

Sony required a structurally rigid, lightweight, and aesthetically refined aluminum lens housing for one of its flagship interchangeable lens models. This optical component had to meet stringent dimensional tolerances, surface cosmetic expectations, and brand identity consistency. Neway was selected as the advanced CNC machining supplier to deliver a one-stop production workflow, from raw turning to finishing.

Why Aluminum 6061 for Optical Lens Housings

Aluminum 6061 strikes the ideal balance between structural performance, corrosion resistance, and surface finish quality—essential for optical component housings.

Property | Value |

|---|---|

Yield Strength | ≥240 MPa |

Surface Finish Suitability | Excellent for coating and blasting |

Weight-to-Strength Ratio | High |

Machinability | Excellent |

Its stable machinability and surface finishing compatibility make it the go-to alloy for consumer electronics, aerospace, and camera-grade optics.

Machining Process Breakdown

CNC Turning (Roughing Stage)

Initial shaping was done through CNC turning, removing bulk material, and establishing concentric references for subsequent milling.

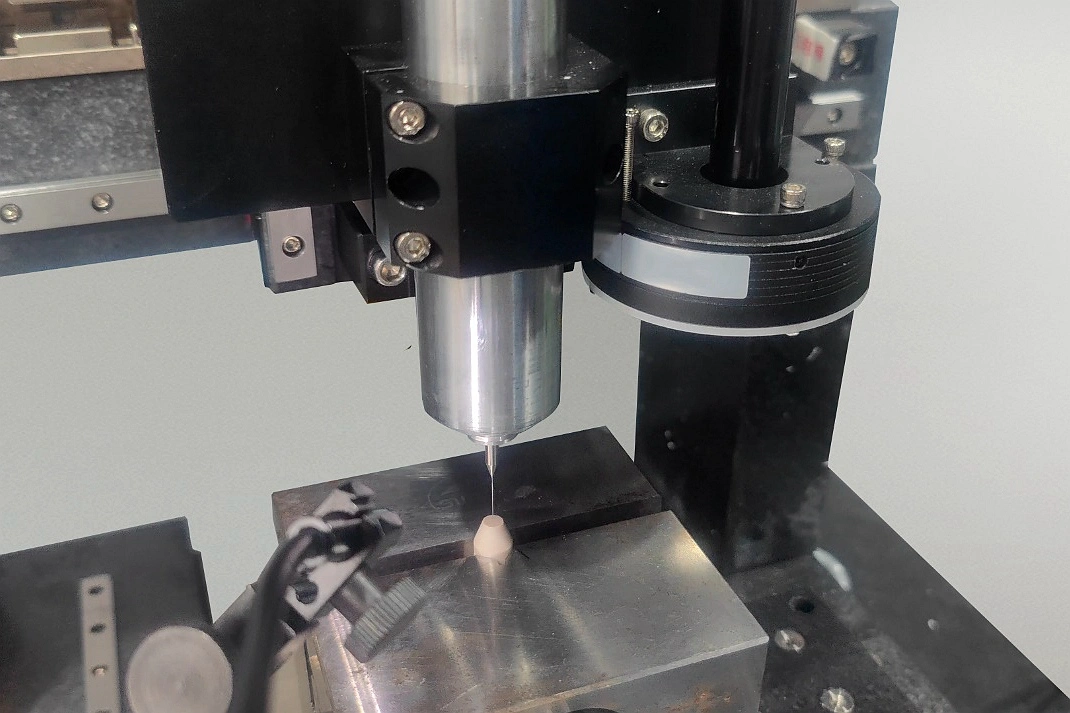

5-Axis CNC Precision Machining

The optical lens shell featured several undercuts, slots, and spiral-threaded rings for the zoom/focus interface. 5-axis CNC machining enabled multi-plane tool access, achieving ±0.01 mm concentricity between critical optical bores and threads.

Surface Treatment Sequence

To ensure both durability and premium appearance, the following steps were performed:

Sandblasting: Delivered a matte, anti-glare finish (~Ra 1.4 μm) ideal for optical-grade housings

Painting: Multi-layer black matte coating optimized for UV stability and wear resistance

Laser Marking: Applied serial number and brand insignia with high contrast and no thermal distortion

Quality Control & Inspection

Dimensional Verification: All threads and optical axis features were inspected with CMM and 3D laser scanning

Surface Testing: Coating adhesion was verified per ASTM D3359; gloss levels controlled under 85° angle standards

Logo Engraving: Verified for clarity and depth using ISO 14782-compliant measurement tools

Production Results

The lens housings were produced in batches of 1,200 units, with zero rejections and >99.5% first-pass yield. Sony reported outstanding consistency in both optical alignment and exterior coating durability. The housing passed thermal cycling and drop shock tests without cosmetic degradation or dimensional shift.

Why Neway for Optical CNC Lens Components

Aluminum CNC Machining: Essential for concentric and angular precision between optical surfaces and threaded mounts

CNC Turning Service: Enables high-speed material removal and accurate cylindrical geometry

One-Stop Manufacturing Service: Complete in-house control over machining, coating, and branding reduces lead time and improves consistency

FAQs

What is the achievable tolerance for optical lens housings using 5-axis CNC machining?

How is coating adhesion tested on CNC machined aluminum parts?

Can painted and sandblasted surfaces maintain uniform appearance across large batches?

What techniques ensure thread-to-bore concentricity on cylindrical lens components?

How does laser marking affect the final surface integrity of painted aluminum parts?