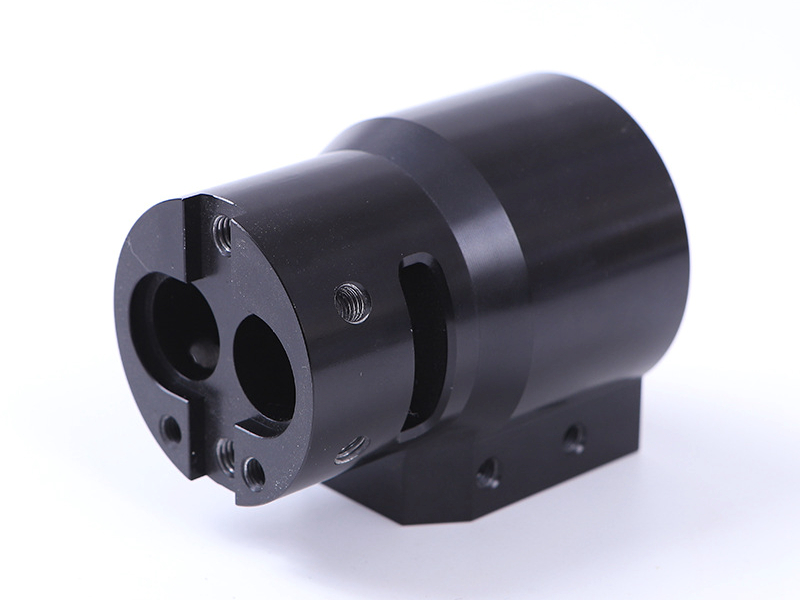

CNC Machining and Black Oxide Finishing for 1020 Steel Automation Module Components

CNC Machining of Automation Components: Durable and Economical Solutions for Modular Systems

Automation module components are critical for precise positioning, structural integration, and motion transfer within high-efficiency systems. These parts must meet tight dimensional tolerances, provide surface protection, and maintain mechanical reliability under continuous operation. At Neway, we specialize in CNC machining and precision machining of 1020 carbon steel for automation systems, delivering robust, dimensionally accurate components tailored to custom modular assemblies.

Post-machining, we apply sandblasting and black oxide coating to enhance corrosion resistance, surface uniformity, and appearance.

Why 1020 Steel Is Ideal for Automation Module Components

Balanced Mechanical Properties and Machinability

1020 steel is a low-carbon alloy with good toughness, machinability, and weldability. With tensile strength around 410–510 MPa and excellent dimensional stability during cutting, it is ideal for brackets, frames, supports, and actuator housings used in automated assemblies.

Cost-Effective for High-Volume Applications

Its affordability and process compatibility make 1020 steel an optimal choice for repeatable part geometries in automation lines where cost-per-unit and reliable performance are key.

CNC and Precision Machining for Automation Modules

Machining for Structural Accuracy and Functional Interfaces

Our machining process covers all essential features for automation integration:

Flatness: ≤ 0.01 mm on mounting surfaces

Hole position tolerance: ±0.02 mm for dowels and fasteners

Surface finish: Ra ≤ 1.6 µm for sliding or contact areas

Precision CNC machining ensures proper alignment with mating components, sensors, and fixtures in modular automation setups.

Tight Tolerance Control and Repeatability

Using high-speed mills and coordinate fixtures, we maintain high consistency for parts that require:

Symmetric slotting or grooving

Tap holes with thread depth control

Frame cutouts with ±0.05 mm dimensional stability

Surface Treatment: Sandblasting and Black Oxide

Sandblasting for Surface Cleanliness and Pre-Coating Texture

Sandblasting removes residual scale and improves adhesion of post-treatments. It ensures a uniform, matte surface texture that visually enhances modules and prepares them for coating.

Black Oxide for Corrosion Protection and Aesthetic Finish

Our black oxide treatment is performed in controlled immersion baths to meet automation-grade standards:

Corrosion resistance in indoor and low-moisture environments

Anti-glare surface ideal for sensor-heavy automation spaces

Minimal dimensional change (<1 µm), preserving machining tolerances

Quality Control and Reporting

CMM inspection of critical fits and flatness

Visual and thickness inspection post-black oxide

Surface finish measurement with profilometers

Material certificate, coating compliance reports, COC available

Why Choose Neway for CNC Automation Module Part Manufacturing

Proven 1020 steel machining with consistent dimensional accuracy

In-house sandblasting and black oxide processing

Low- to high-volume production capability with fast setup and tooling

One-stop CNC manufacturing including machining, finishing, and packaging

CNC Services for Automation Component Projects

Neway supports automation equipment integrators with complete part manufacturing for frame assemblies, precision brackets, and system modules. Services include:

Precision CNC Machining: For structural and dynamic features

1020 Steel CNC Production: Strong, stable parts for structural roles

Black Oxide Finishing: Low-cost corrosion resistance for internal-use parts

We help manufacturers meet the speed, precision, and durability requirements of modern automation.

FAQs

What tolerances can be achieved for CNC-machined 1020 automation parts?

How durable is black oxide finish for industrial automation environments?

Does sandblasting affect part dimensions or hole quality?

What batch sizes can Neway support for CNC automation components?

Are inspection reports and surface treatment certifications provided?