Multi-Axis CNC Machining of PEEK Turbo Rotor for Honeywell

Project Background: Lightweight High-Performance Turbo Rotors

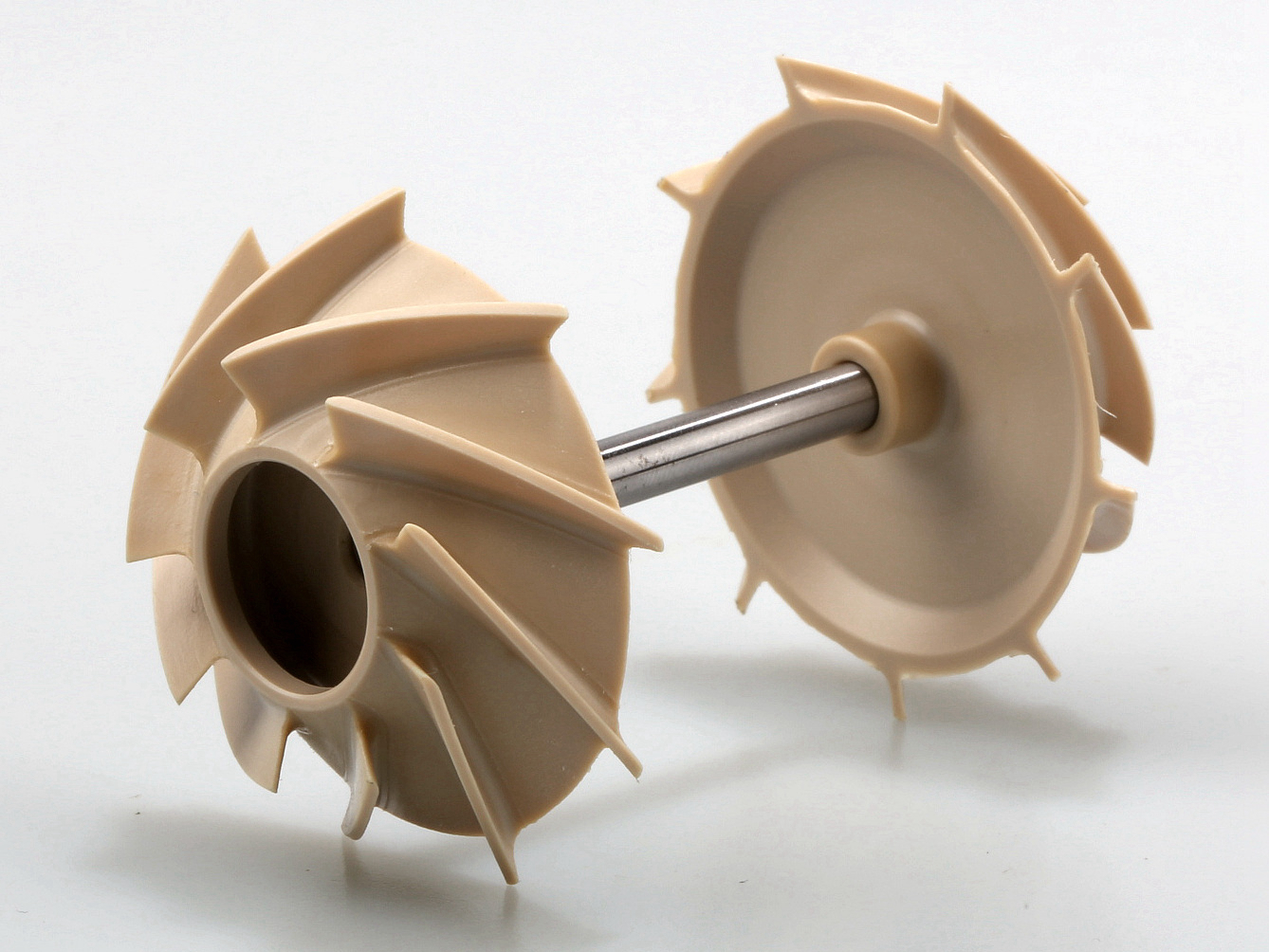

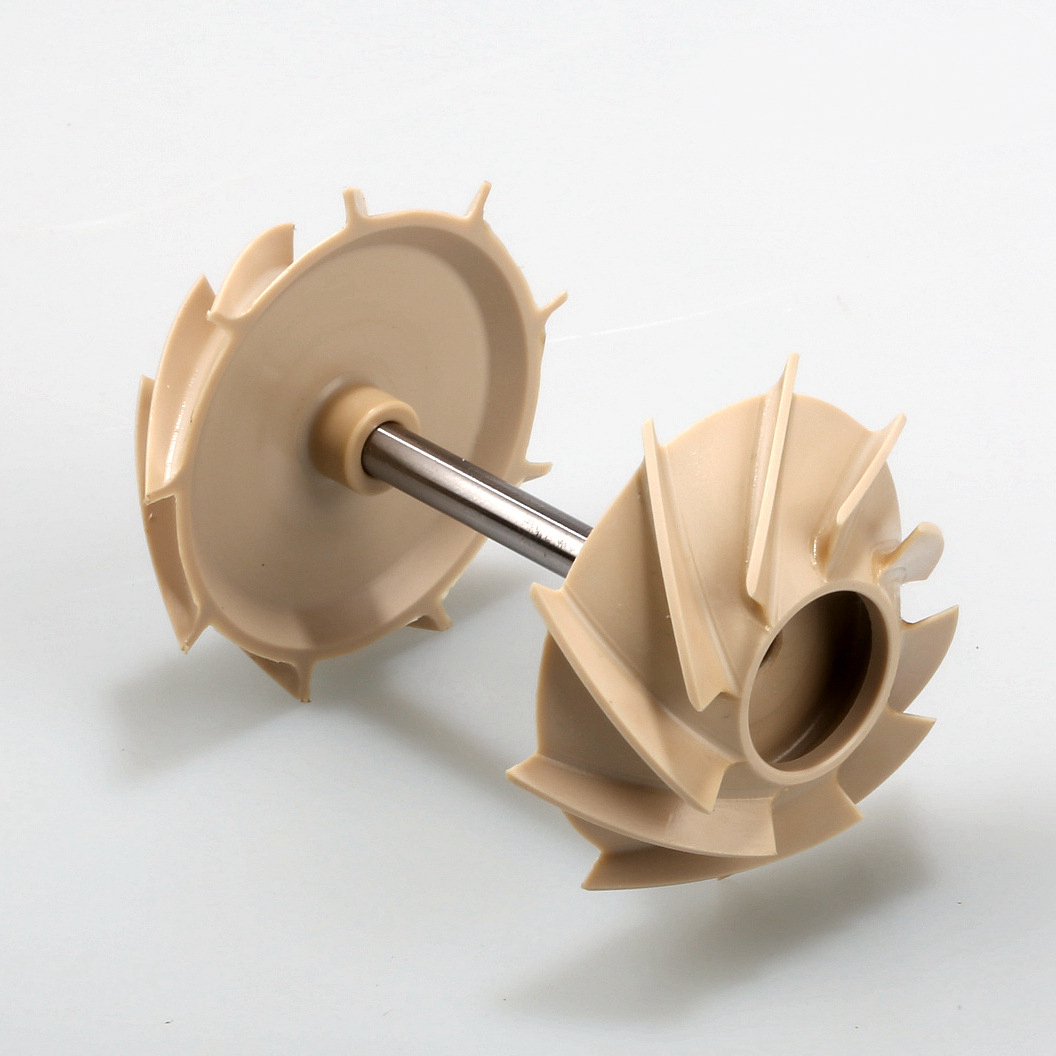

Honeywell required a high-speed, chemically resistant, and lightweight turbo rotor component for use in precision airflow control systems. The material needed to maintain dimensional stability under thermal cycling and high rotational velocity. Neway was selected to deliver complete CNC machining of this component using PEEK (Polyether Ether Ketone), a high-performance thermoplastic widely adopted in aerospace and industrial sectors.

Why PEEK Was Chosen for Turbo Rotor Applications

PEEK offers outstanding thermal stability, wear resistance, and chemical durability—making it ideal for advanced rotor applications.

Property | Value |

|---|---|

Continuous Use Temperature | Up to 260°C |

Tensile Strength | ≥90 MPa |

Density | 1.3 g/cm³ |

Chemical Resistance | Excellent (fuels, oils, steam) |

Machinability | High (with proper fixturing) |

PEEK maintains its mechanical integrity and dimensional stability even under combined chemical and thermal stress. Learn more about PEEK CNC Machining.

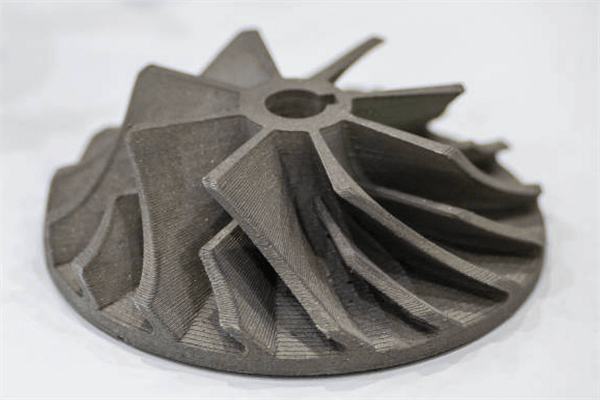

CNC Machining Process Overview

CNC Turning for Rotor Profile

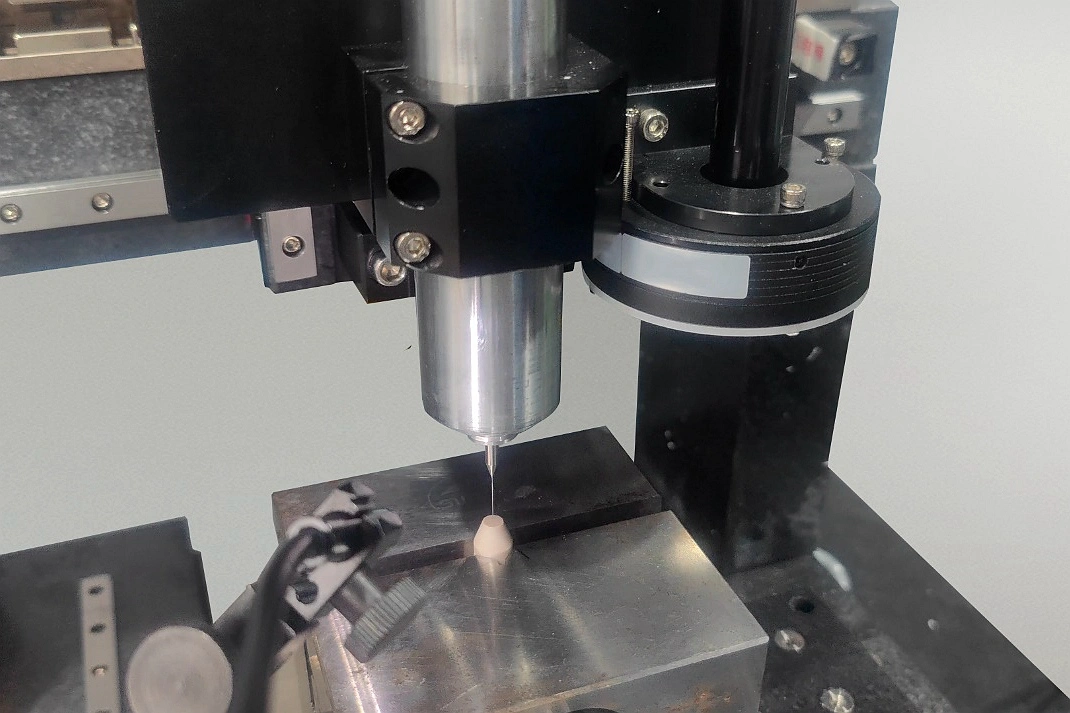

Initial profiling and central shaft feature formation were performed using CNC turning. PEEK was turned at low RPM to prevent material softening, with sharp carbide inserts used to maintain surface quality.

Multi-Axis CNC Finishing

To achieve precision on curved vane features and concentric balance, multi-axis CNC machining was applied. This enabled undercut detailing and pitch control in a single setup, maintaining balance tolerances within ±0.01 mm.

Quality Control and Testing

Dimensional Accuracy: All shaft and vane features were measured with a high-resolution CMM

Balance Testing: Dynamic balancing validated rotor concentricity for high-speed operation

Surface Finish: Rotor surfaces achieved Ra ≤ 0.8 μm, critical for airflow efficiency and vibration suppression

Project Outcome

Neway delivered a batch of 1,200 turbo rotors for Honeywell’s aerospace-grade airflow management system. All parts passed centrifugal stress testing, thermal cycling, and vibration validation. Honeywell reported increased rotor performance due to superior concentricity and consistent dimensional quality.

Why Neway for Plastic CNC Turbo Components

Plastic CNC Machining: Expert handling of high-performance polymers like PEEK for tight-tolerance industrial parts

Multi-Axis CNC Machining: Enables complex geometry and concentric balancing in aerodynamic components

CNC Turning Service: Delivers accurate rotational features with minimized tool-induced distortion

FAQs

How does PEEK perform under continuous high-speed rotation?

What precautions are necessary when CNC machining PEEK to prevent thermal deformation?

Can PEEK be dynamically balanced like metal rotors?

What is the minimum wall thickness achievable for precision PEEK rotor blades?

How does multi-axis machining improve rotor symmetry in plastic parts?