¿Por qué las tolerancias ajustadas aumentan los costos del mecanizado CNC?

¿Por qué las tolerancias ajustadas aumentan los costos del mecanizado CNC?

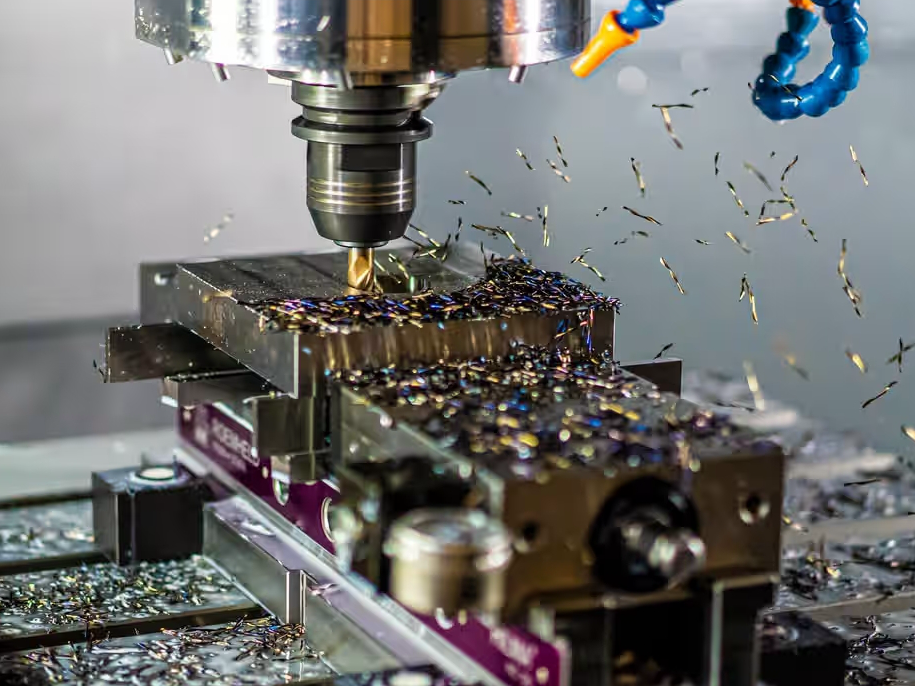

Las tolerancias ajustadas —normalmente definidas como ±0,01 mm o más finas— son esenciales para los componentes de alto rendimiento, pero afectan significativamente los costos del mecanizado CNC. En Neway, aplicamos ingeniería de tolerancias basada en la necesidad funcional, asegurando que la precisión se entregue solo donde aporta valor. A continuación, explicamos por qué las tolerancias ajustadas incrementan el costo y cómo los compradores pueden optimizar el rendimiento sin gastar de más.

Velocidades de mecanizado más lentas y múltiples pasadas

Lograr tolerancias ajustadas requiere reducir las velocidades de corte y los avances para evitar la deflexión de la herramienta, la acumulación de calor y la vibración. Esto a menudo duplica o triplica el tiempo de mecanizado en comparación con el trabajo de tolerancia general. En muchos casos, se programan pasadas de semiacabado y acabado adicionales para aproximarse gradualmente a la dimensión final.

Herramientas de alta precisión y compensación del desgaste

Las piezas que requieren ±0,005 mm o mejor deben cortarse con herramientas calibradas como fresas de extremo recubiertas de diamante, insertos ultrafilosos o herramientas de acabado rectificadas. Estas herramientas son más costosas y se desgastan más rápido. Las rutinas de compensación por desgaste de herramienta y los sistemas de medición en proceso aumentan aún más el costo.

Utillajes especializados y control térmico

Las tolerancias ajustadas en dimensiones críticas a menudo requieren fijaciones personalizadas con control preciso de referencia y sujeción estable. Además, una variación de temperatura de solo 5 °C puede alterar las dimensiones metálicas en 5–10 micras. Por lo tanto, los entornos de producción deben admitir servicios de mecanizado CNC bajo condiciones de estabilidad térmica.

Mayor inspección y control de calidad

La verificación dimensional de piezas de alta precisión requiere CMMs, micrómetros láser o comparadores ópticos. El tiempo de control de calidad aumenta entre 3 y 5 veces debido a múltiples puntos de inspección, documentación y validación de tolerancias según las normas ISO 2768-fH o AS9100.

Más detalles: ¿Cuál es la tolerancia más ajustada que puede lograr Neway?

Mayor riesgo de tasa de rechazo

El desgaste leve de la herramienta o la deriva térmica pueden provocar desviaciones fuera de los límites ultraajustados, especialmente en el mecanizado de superaleaciones. Las piezas rechazadas o retrabajadas aumentan el costo efectivo por pieza, lo que se refleja en las cotizaciones de precios.

Ejemplo de caso: soporte de aluminio 7075 (±0,01 mm vs ±0,05 mm)

Nivel de tolerancia | Tiempo de mecanizado | Tiempo de control de calidad | Incremento de costo |

|---|---|---|---|

±0,05 mm (estándar) | 25 min | 5 min | — |

±0,01 mm (ajustada) | 55 min | 20 min | +70–120 % |

Las especificaciones más estrictas resultan en tiempos de ciclo más largos, más verificaciones de herramientas y ciclos adicionales de control de calidad.

Recomendación de diseño

Aplica tolerancias ajustadas solo a características de acoplamiento, sellado o rotación. Utiliza tolerancias más amplias (±0,1–0,2 mm) en superficies no funcionales. Consulta con tu proveedor CNC para identificar dimensiones críticas y simplificar la inspección.

Servicios de fabricación que puede necesitar

Neway ofrece soluciones completas de mecanizado CNC, que incluyen producción de tolerancia ajustada, inspección CMM y mecanizado de piezas de superaleación. Servimos a los sectores aeroespacial, médico e industrial con precisión de ±0,01 mm y trazabilidad de calidad completa.