Tolerances in CNC Machining: Balancing Precision, Functionality and Cost Analysis

Introduction

Tolerances are a cornerstone of CNC machining, defining the acceptable variation in a part’s dimensions and geometry. In modern manufacturing, precision-driven sectors such as aerospace, medical devices, and semiconductors demand increasingly tighter tolerances to meet performance and safety standards. According to recent market data, the global high-precision CNC machining market is projected to grow at a CAGR of 6.7% through 2028, driven by advancements in material science and digital manufacturing. In this context, finding the right balance between precision, functionality, and cost has become critical for competitive production.

CNC Machining Tolerance Classifications and Standards

Tolerances in CNC machining encompass several categories: dimensional tolerances, geometric tolerances (as defined by GD&T), and surface finish tolerances. Each plays a crucial role in ensuring that a component performs its intended function.

Dimensional tolerances govern linear dimensions (e.g., ±0.01 mm), while geometric tolerances control form and position attributes such as flatness, parallelism, and concentricity. Surface finish tolerances, often specified as the roughness average (Ra), determine a part’s texture and suitability for applications such as sealing or wear resistance.

Global standards, such as ISO 2768 and ASME Y14.5-2018, provide frameworks for specifying and interpreting tolerances. Different industries adopt these standards to varying degrees:

Aerospace components, such as those in Inconel 718, typically require tolerances tighter than ±0.005 mm to ensure performance at high temperatures and stresses, as demonstrated in this Inconel 718 aerospace CNC machining case.

Medical devices, such as surgical implants and zirconia blades, require tolerances of ±0.01 mm or better to ensure compatibility with human anatomy, as shown in zirconia ceramic CNC machining for surgical blades.

Automotive components often target tolerances of ±0.02 mm, while precision electronic connectors require tolerances of ±0.005 mm or less for reliable electrical performance.

Tolerances directly impact a part’s fit, function, and durability. For example, interference fits in gear assemblies demand extremely tight tolerances to ensure load transfer without slippage, while clearance fits in bearings require controlled gaps to allow smooth rotation.

Cost Implications of Tolerance Precision

The pursuit of tighter tolerances introduces a nonlinear cost curve in CNC machining. Achieving a tolerance of ±0.02 mm may be economical on standard CNC milling equipment, but reducing the tolerance to ±0.005 mm can escalate costs by 300% to 500%, due to slower machining speeds, increased tool wear, and more frequent quality checks.

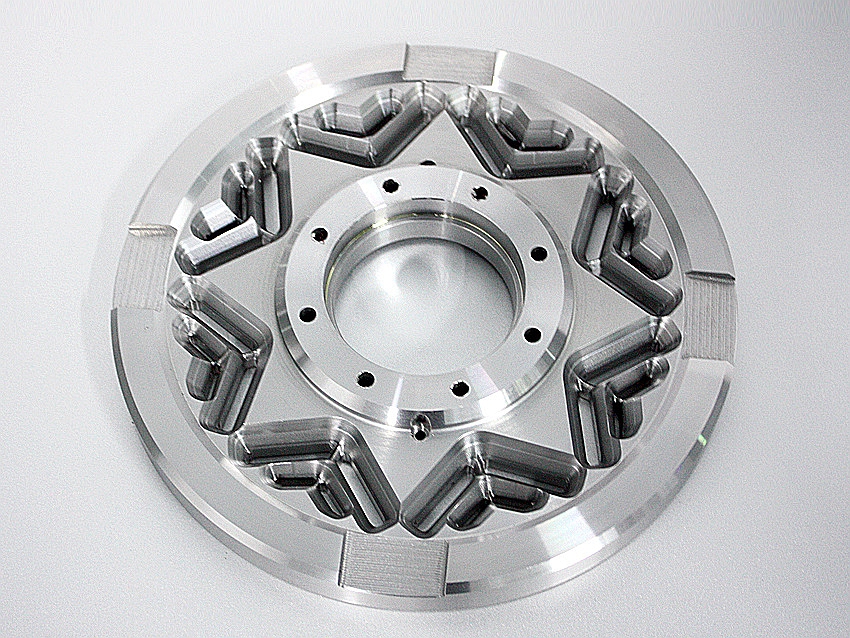

High-precision machining often necessitates advanced equipment such as 5-axis CNC machines or specialized grinding services. For example, achieving sub-5-micron tolerances on aerospace turbine components may require multi-axis machining with integrated thermal compensation, as seen in bronze CNC-milled steam turbine components.

Tooling is another significant factor. High-performance materials, such as titanium and superalloys, which are frequently used in industries like aerospace and oil & gas, require premium PCD or CBN tooling. This not only increases tool costs but also reduces tool life, resulting in higher per-part expenses.

Inspection costs also rise sharply with tighter tolerances. Precision coordinate measuring machines (CMMs) and laser scanners are essential for verification, complementing time-consuming full inspection protocols. In applications such as medical stainless steel surgical instruments, stringent regulatory requirements further complicate inspection complexity and increase costs.

Practical Strategies for Setting Tolerances

The key to cost-effective tolerance management lies in a collaborative design approach. Early-stage integration of manufacturing feedback, through Design for Manufacturability (DFM) and Design to Cost (DTC) methodologies, ensures that only critical features are assigned ultra-tight tolerances.

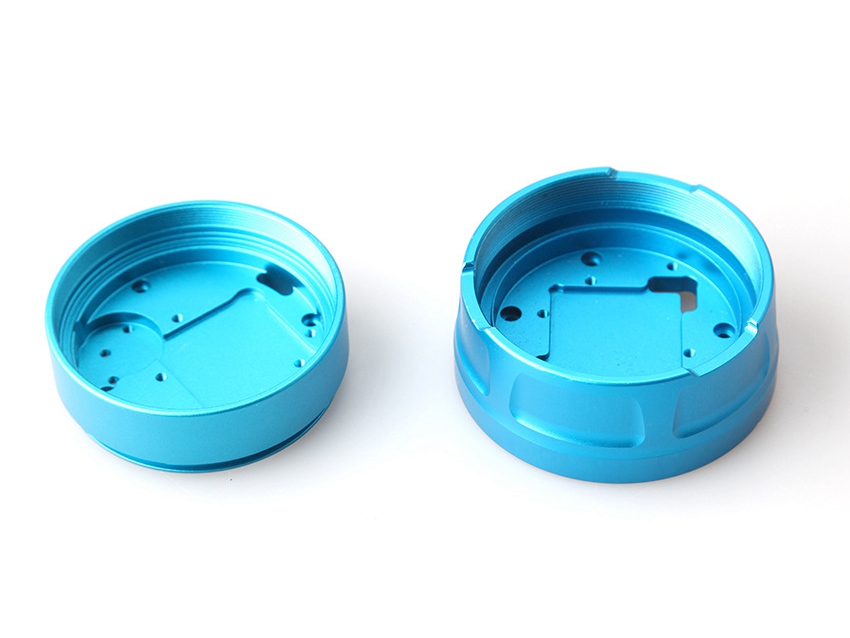

Rather than specifying a blanket ±0.01 mm tolerance across an entire component, engineers should apply functional tolerance zoning. For example, in a medical implant, joint surfaces may require a tolerance of ±0.005 mm, while non-mating areas can be relaxed to ±0.05 mm. This selective approach optimizes machining efficiency without compromising part performance.

In a recent aerospace project, one customer collaborated with Neway engineers to adjust non-critical tolerances on turbine housing components. This resulted in a 28% cost reduction and a 15% improvement in cycle time, without compromising part functionality.

Applications of Smart Manufacturing in Tolerance Control

Smart manufacturing technologies are transforming tolerance management. Real-time process monitoring and adaptive control systems are increasingly used to stabilize machining conditions and prevent tolerance drift.

For example, in multi-axis machining of complex aerospace components, digital twin models simulate machining behavior, enabling predictive adjustments to maintain dimensional accuracy throughout a batch run. CNC equipment with closed-loop feedback can autonomously compensate for thermal growth or tool wear.

Artificial intelligence further enhances tolerance optimization. By analyzing historical machining data, AI algorithms can suggest optimal tool paths and cutting parameters, improving accuracy and reducing cycle times. These advancements are particularly valuable in sectors such as semiconductor tooling, where tolerances of 0.001 mm or less are required.

Automated inspection systems now integrate CMM data with CNC controls, creating a closed-loop correction process. This approach is used in the precision machining of advanced robotics components, such as those featured in robotics aluminum CNC milling solutions.

Typical Industry Tolerance Case Studies

Different industries illustrate how specific tolerance levels align with performance and safety requirements:

In medical applications, titanium implants and ceramic components, such as zirconia CNC-machined blades, require tolerances of ±0.005 mm to ensure proper integration with biological tissues and avoid postoperative complications.

Semiconductor manufacturing demands even greater precision. Optical components and lithography stages require flatness tolerances of less than 0.001 mm and surface roughness values of Ra 0.1 μm to support sub-10 nm feature sizes.

In the automotive sector, electric motor housings rely on high-concentricity tolerances of ≤0.01 mm to optimize motor efficiency and reduce noise and vibration. An example can be seen in automotive titanium CNC machined valve components, where critical sealing surfaces require ultra-tight tolerances for leak-free operation.

These examples demonstrate that tolerance selection must be driven by both functional requirements and industry-specific standards, rather than arbitrary design choices.

Conclusion and Future Trends

In CNC machining, tolerances fundamentally dictate part quality, functionality, and production economics. Striking the optimal balance between precision and cost requires thoughtful design, collaborative engineering, and strategic application of smart manufacturing technologies.

Looking ahead, AI-driven machining, advanced process monitoring, and fully integrated digital twins will further enhance manufacturers’ ability to achieve tighter tolerances while maintaining cost efficiency. Companies that embrace these innovations will gain a competitive edge in high-value sectors such as aerospace, medical devices, and next-generation automotive systems.

For buyers and engineers, understanding the interplay between tolerance, function, and cost is no longer optional—it is essential to driving quality and profitability in today’s precision manufacturing landscape.