خدمة الطباعة ثلاثية الأبعاد بالراتنج واللدائن الحرارية | احصل على عرض سعر

المقدمة: اختيار أفضل حل للطباعة البلاستيكية ثلاثية الأبعاد لأفكارك ومشاريعك

في تطوير المنتجات الحديثة، أصبحت السرعة والمرونة هما مفتاح الفوز في السوق. بوصفها ركيزة أساسية للنمذجة السريعة، تُحدث الطباعة البلاستيكية ثلاثية الأبعاد ثورة في رحلة الانتقال من الفكرة إلى المنتج النهائي. سواء كنت بحاجة إلى نموذج مفهومي ملموس أو جزء وظيفي بالكامل يجب أن يتحمل اختبارات صارمة، فإن اختيار عملية الطباعة والمادة المناسبة أمر بالغ الأهمية. أمام تعدد التقنيات مثل SLA وSLS وFDM، وتنوع المواد المتاحة، يبرز السؤال: كيف تتخذ قرارًا اقتصاديًا وملائمًا للتطبيق؟ بصفتنا شريكك الموثوق في التصنيع، تهدف نيوي من خلال هذا الدليل إلى توضيح خياراتك وتقديم خدمات تسعير سريعة وشفافة، حتى تتحول أفكارك إلى واقع بسلاسة.

نظرة عامة على التقنيات الأساسية: مبادئ العمليات وميزات SLA وSLS وFDM

للوصول إلى اختيار مدروس، من الضروري أولًا فهم المبادئ الأساسية والمزايا الفريدة لثلاث من أشهر تقنيات الطباعة البلاستيكية ثلاثية الأبعاد.

SLA (Stereolithography): معروفة بالدقة وجودة السطح تستخدم تقنية SLA ليزر UV عالي الدقة لمسح سطح راتنج ضوئي سائل (Photopolymer Resin) بشكل انتقائي، بحيث تُحفَّز عملية البلمرة الضوئية وفقًا للهندسة المقطعية المحددة مسبقًا لتصلّب طبقة الراتنج. بعد تصلب طبقة واحدة، تتحرك منصة البناء، وتُطبَّق طبقة رقيقة جديدة من الراتنج، ثم يستمر الليزر في مسح الطبقة التالية. تتكرر هذه الدورة حتى يكتمل الجزء. تشتهر SLA بدقة طباعة لا تُضاهى، وتشطيب سطحي ناعم للغاية، وقدرة ممتازة على إبراز التفاصيل الدقيقة، مما يجعلها مثالية لنماذج العرض، والأعمال الفنية الدقيقة، ونماذج التحقق من المظهر.

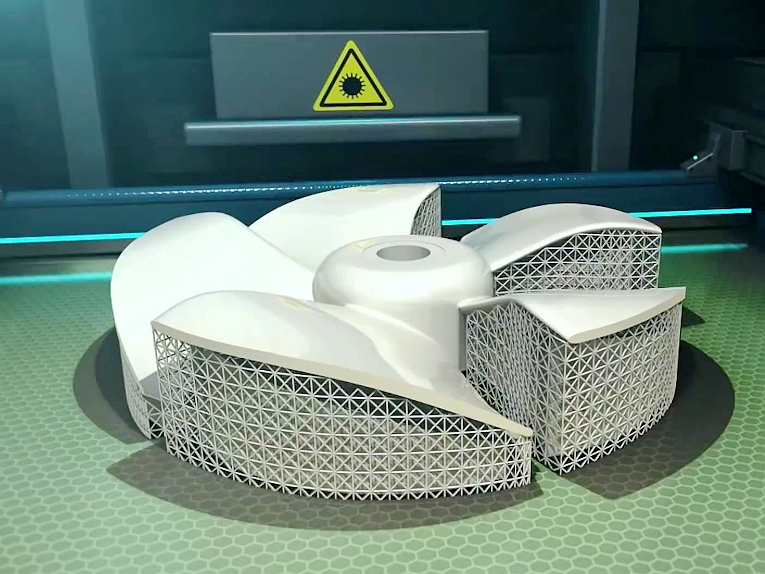

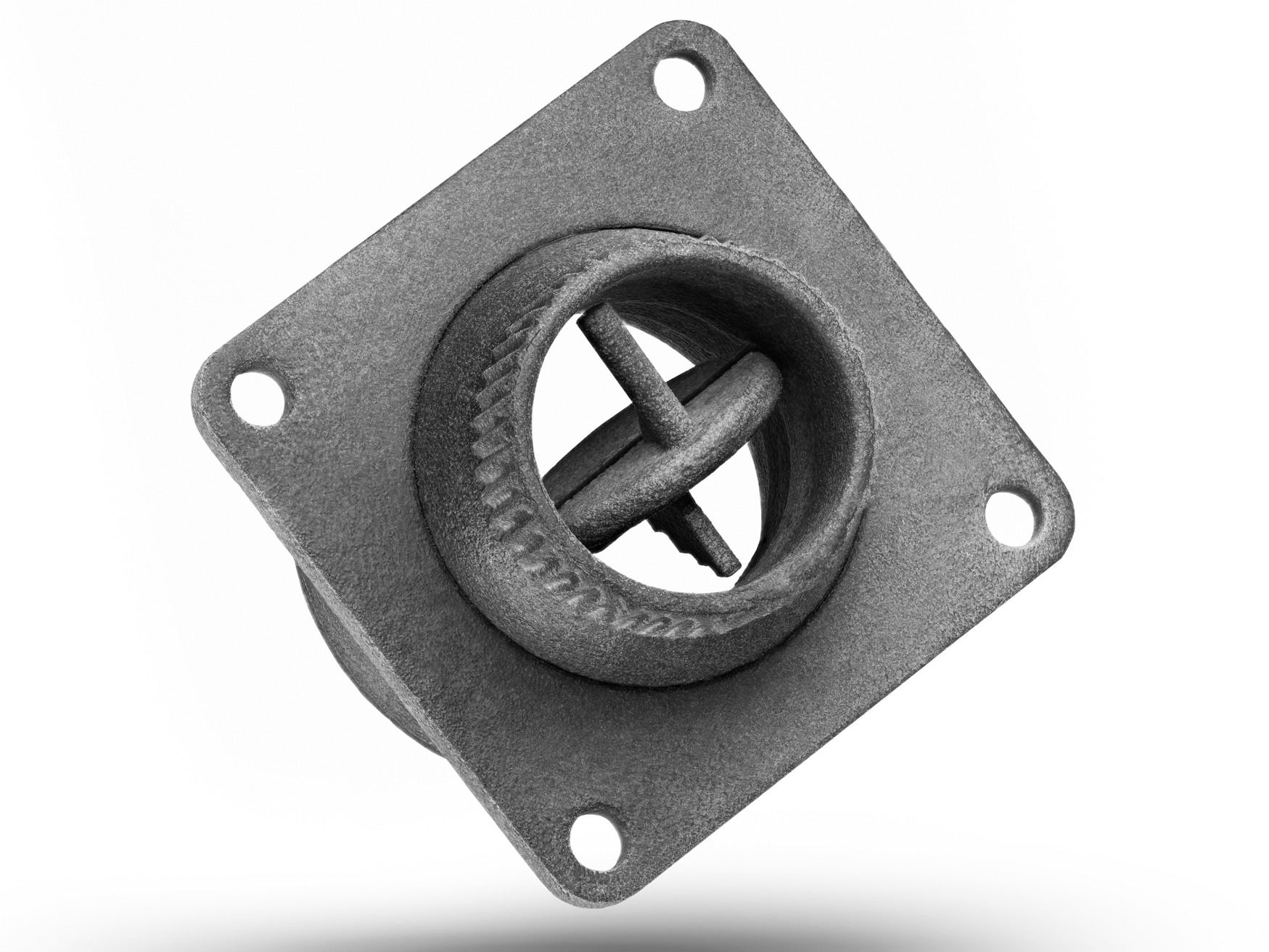

SLS (Selective Laser Sintering): أداء قوي للأجزاء الوظيفية والمتكاملة تعتمد تقنية SLS على ليزر عالي القدرة لفرنسة/تلبيد مساحيق الثرمو بلاستيك مثل النايلون بشكل انتقائي. تتم العملية بالكامل داخل حجرة مسخنة مملوءة بغاز واقٍ. تذوب جزيئات المسحوق التي يمسحها الليزر وتلتحم معًا، بينما يعمل المسحوق غير الملبّد بشكل طبيعي كدعم للجزء. يتيح ذلك لـ SLS إنتاج قنوات داخلية معقدة، ومفصلات عاملة (Working Hinges)، وهياكل متشابكة. تتمتع الأجزاء الناتجة بخصائص ميكانيكية ممتازة وقريبة من الخواص متساوية الخواص (Isotropic)، ما يجعل SLS خيارًا مثاليًا للاختبارات الوظيفية والإنتاج منخفض الكمية.

FDM (Fused Deposition Modeling): أداة اقتصادية للتحقق السريع تُعد FDM أكثر تقنيات الطباعة ثلاثية الأبعاد انتشارًا. تقوم هذه التقنية بتسخين خيط ترموبلاستيك (مثل ABS أو PC) إلى حالة شبه منصهرة، ثم بثقه من خلال فوهة، لترسيبه طبقة بعد طبقة على منصة البناء. تتمثل المزايا الرئيسية لـ FDM في التكلفة المنخفضة، وانفتاح منظومة الأجهزة، وتوافر المواد بشكل واسع. ورغم أن الأجزاء المنتَجة غالبًا ما تُظهِر خطوط طبقات واضحة ودقة أقل نسبيًا، تظل FDM الحل الأكثر اقتصادية وكفاءة للتحقق المفاهيمي، وفحص التصميم، والأدوات البسيطة والجيجات.

دليل اختيار المواد: من الراتنجات الصلبة إلى النايلون الهندسي

التقنية تُحدد الإطار؛ أما المادة فهي التي تمنح الجزء أداءه الحقيقي. كل تقنية طباعة تقترن بنظام مواد متنوع.

عائلة الراتنجات الضوئية: لأعلى درجات المظهر والأداء المتخصص في طباعة SLA، يُحدّد اختيار الراتنج الخصائص النهائية للجزء. توفر الراتنجات القياسية توازنًا جيدًا بين التكلفة وجودة السطح والقوة، ما يجعلها مناسبة للتحقق الفيزيائي قبل النمذجة الأولية على CNC. يمكن للراتنجات المتينة (Tough Resins) محاكاة مقاومة الصدمات والليونة للمواد البلاستيكية الهندسية مثل البولي بروبيلين، مما يجعلها مثالية للأجزاء ذات المشابك (Snap-Fits)، والأغلفة، وأجزاء النماذج الأولية الحاملة للأحمال. أما الراتنجات عالية الحرارة، فبإمكانها الحفاظ على ثبات الأبعاد عند درجات حرارة مرتفعة، لتناسب اختبارات الموائع الحرارية، والأجزاء القريبة من المحرك، وغيرها من التطبيقات المشابهة.

مواد مسحوق النايلون: لأجزاء وظيفية وإنتاج منخفض الكمية يُعد النايلون (Polyamide) المادة الأساسية لتقنية SLS. يوفر النايلون القياسي (PA12) قوة ممتازة، وصلابة جيدة، ومقاومة بارزة للتعب. الأجزاء خفيفة الوزن والمتينة المصنوعة من هذه المادة تُعد خيارًا مفضلًا للاختبارات الوظيفية ضمن خدمات النمذجة الأولية. من خلال إضافة حبيبات زجاجية (PA-GF) أو مسحوق ألومنيوم (PA-AF)، يمكن رفع الصلابة ودرجة حرارة التشوّه الحراري بشكل كبير، مما يتيح تصنيع مكونات أكثر تحملًا. أما النايلون 11 فيتميز بمرونة أعلى ومقاومة أفضل للصدمات، وهو مثالي للمفصلات الحية (Living Hinges)، والمشابك، والأجزاء التي تتعرض للثني المتكرر.

خيوط الثرمو بلاستيك الهندسية في FDM تدعم FDM أوسع نطاق من المواد الهندسية. يُعتبر ABS من أكثر المواد استخدامًا لما يوفره من قوة ميكانيكية جيدة، ومقاومة للحرارة، وسهولة في المعالجة. يبرز البولي كربونيت (PC) بقوته العالية جدًا، ومقاومته الحرارية الممتازة، وشفافيته، ما يجعله مناسبًا للمكونات الوظيفية القوية والأغلفة الشفافة. في التطبيقات الأكثر تطلبًا، يمكن استخدام مواد عالية الأداء مثل PEEK (بولي إيثر إيثر كيتون) لتلبية المتطلبات القصوى للبيئات القاسية.

كيف تختار؟ جدول مقارنة بين SLA وSLS وFDM

لدعم اتخاذ القرار بشكل أسرع، أعددنا جدول المقارنة التالي:

الخاصية | SLA (Stereolithography) | SLS (Selective Laser Sintering) | FDM (Fused Deposition) |

|---|---|---|---|

أقصى دقة | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

جودة السطح | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ |

القوة الميكانيكية | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

تعقيد البنية | مرتفع (يتطلّب دعامات) | مرتفع جدًا (لا يحتاج إلى دعامات) | متوسط (يتطلّب دعامات) |

التطبيقات النموذجية | نماذج عرض، أجزاء ذات تفاصيل دقيقة | أجزاء وظيفية، هياكل معقدة | تحقق مفاهيمي، أدوات / جيجات بسيطة |

التكلفة النسبية | متوسطة | متوسطة–مرتفعة | منخفضة |

مسار اتخاذ القرار:

إذا كان أولويتك القصوى هي الحصول على تفاصيل فائقة الدقة، وأسطح ناعمة، وأجزاء شفافة أو نماذج عرض، فاختر SLA.

إذا كنت بحاجة إلى اختبارات وظيفية، أو أجزاء متكاملة ذات هياكل داخلية معقدة، أو إنتاج منخفض الكمية ضمن خدمات التصنيع منخفض الكمية، فإن SLS هو الخيار الأفضل.

إذا كان لديك ميزانية محدودة، أو حجم الجزء كبير، أو تحتاج فقط إلى تحقق سريع لتصاميم بسيطة، فإن FDM يوفر الحل الأكثر اقتصادية.

خيارات المعالجة اللاحقة والتشطيب الشائعة للطباعة البلاستيكية ثلاثية الأبعاد

الطباعة ليست سوى الخطوة الأولى؛ إذ يمكن للمعالجة اللاحقة الصحيحة أن ترفع القيمة النهائية لأجزائك بشكل كبير.

إزالة الدعامات والصنفرة الأساسية: تُعد هذه الخطوة ضرورية لتنظيف الأجزاء بعد الطباعة بجميع التقنيات. بالنسبة لأجزاء SLS، يمكن لـ خدمات التلميع البرميلي وإزالة الرايش لأجزاء CNC إزالة المسحوق المتبقي بفعالية وإضفاء مظهر مطفي موحد.

تنعيم السطح والتلوين:

لأجزاء SLA، يمكن لـ خدمات تلميع أجزاء CNC تحقيق لمعان أعلى وتشطيب يشبه المرآة.

لتحقيق مظهر واقعي، توفر حلول طلاء أجزاء CNC طبقات ملونة متينة تناسب مختلف الأجزاء البلاستيكية المطبوعة.

تعزيز الأداء:

بالنسبة لأجزاء SLA، يساعد تطبيق طلاء UV لأجزاء البلاستيك المشغّلة على CNC في تحسين صلابة السطح، ومقاومة التآكل، وثباتية الأشعة فوق البنفسجية بشكل ملحوظ، مما يمنع الاصفرار والشيخوخة مع مرور الوقت.

سيناريوهات تطبيق نموذجية لخدمات الطباعة البلاستيكية ثلاثية الأبعاد

المنتجات الاستهلاكية: تُستخدم SLA وSLS على نطاق واسع في التحقق من المظهر، واختبارات بيئة الاستخدام، ونماذج التسويق للأجهزة الإلكترونية، والأجهزة القابلة للارتداء، والأجهزة المنزلية.

المعدات الطبية: تُستخدم SLA عالية الدقة لإنتاج نماذج أولية لأدلة جراحية، بينما تُستغل الراتنجات الحيوية التوافق والنايلون لطباعة أغلفة ومقابض الأدوات الطبية، دعمًا للاختبارات السريرية وملفات الاعتماد التنظيمية.

قطاع السيارات: تُستخدم FDM وSLS في تصنيع نماذج تحقق من الملاءمة الداخلية (Interior Fit-Check Prototypes)، وتجهيزات توجيه في حيز المحرك، وأدوات قوالب سريعة (Rapid Molding) لخطوط الإنتاج. يمكن دعم ذلك بتقنيات القوالب السريعة لتقريب ظروف الإنتاج الفعلية.

لماذا تختار نيوي لخدمات الطباعة البلاستيكية ثلاثية الأبعاد؟

في نيوي، ندرك أن الطباعة ثلاثية الأبعاد ليست مجرد طريقة تصنيع، بل هي محفّز للابتكار. بفضل مجموعات متقدمة من معدات SLA وSLS وFDM، نضمن القدرة على ترشيح وتنفيذ أنسب حل تقني لمشروعك. نقوم بتحديث محفظة المواد لدينا باستمرار، بدءًا من الراتنجات الأساسية والنايلون وصولًا إلى البلاستيك الهندسي المتقدم مثل أسيتال (POM – Polyoxymethylene) و بولي كربونيت (PC)، لتغطية نطاق واسع من التطبيقات من نماذج العرض البصرية إلى الأجزاء الوظيفية. الأهم من ذلك، أننا نوفر خدمة متكاملة (One-Stop Service) تشمل كل ما تحتاجه: من الاستشارات التقنية وتنفيذ الطباعة، إلى المعالجة اللاحقة الاحترافية مثل عمليات السفع الرملي لأجزاء CNC و تشطيبات الطلاء بالمسحوق لأجزاء CNC. وعندما يتطلب مشروعك قوة أعلى أو إنتاجًا على نطاق أكبر، تندمج خدمات التشغيل الدقيق و خدمات الإنتاج الكمي بسلاسة لتوفير دعم تصنيع لاحق قوي.

احصل على عرض السعر المخصص الآن: عملية بسيطة وشفافة

الحصول على عرض سعر لم يكن يومًا بهذه السهولة. ما عليك سوى زيارة منصتنا عبر الإنترنت، ورفع ملفات النماذج ثلاثية الأبعاد الخاصة بك (STL/OBJ)، واختيار عملية الطباعة والمادة المناسبة وفقًا لإرشاداتنا. سيقوم نظامنا تلقائيًا بإنشاء عرض سعر أولي، أو يقوم فريقنا الهندسي بمراجعة سريعة يدويًا للتحقق من قابلية الطباعة واقتراح التحسينات، ثم تقديم عرض سعر نهائي شفاف بلا أي رسوم مخفية. بعد التأكيد، يمكنك تقديم طلبك فورًا، وسنبدأ الإنتاج مباشرة. إن فكرتك لا تبعد سوى خطوة واحدة عن أن تصبح واقعًا ملموسًا.