Low-Volume CNC Machining Manufacturing of 12L14 Steel for Precision Shafts and Bolts

Introduction to Low-Volume CNC Machined 12L14 Steel in Precision Component Manufacturing

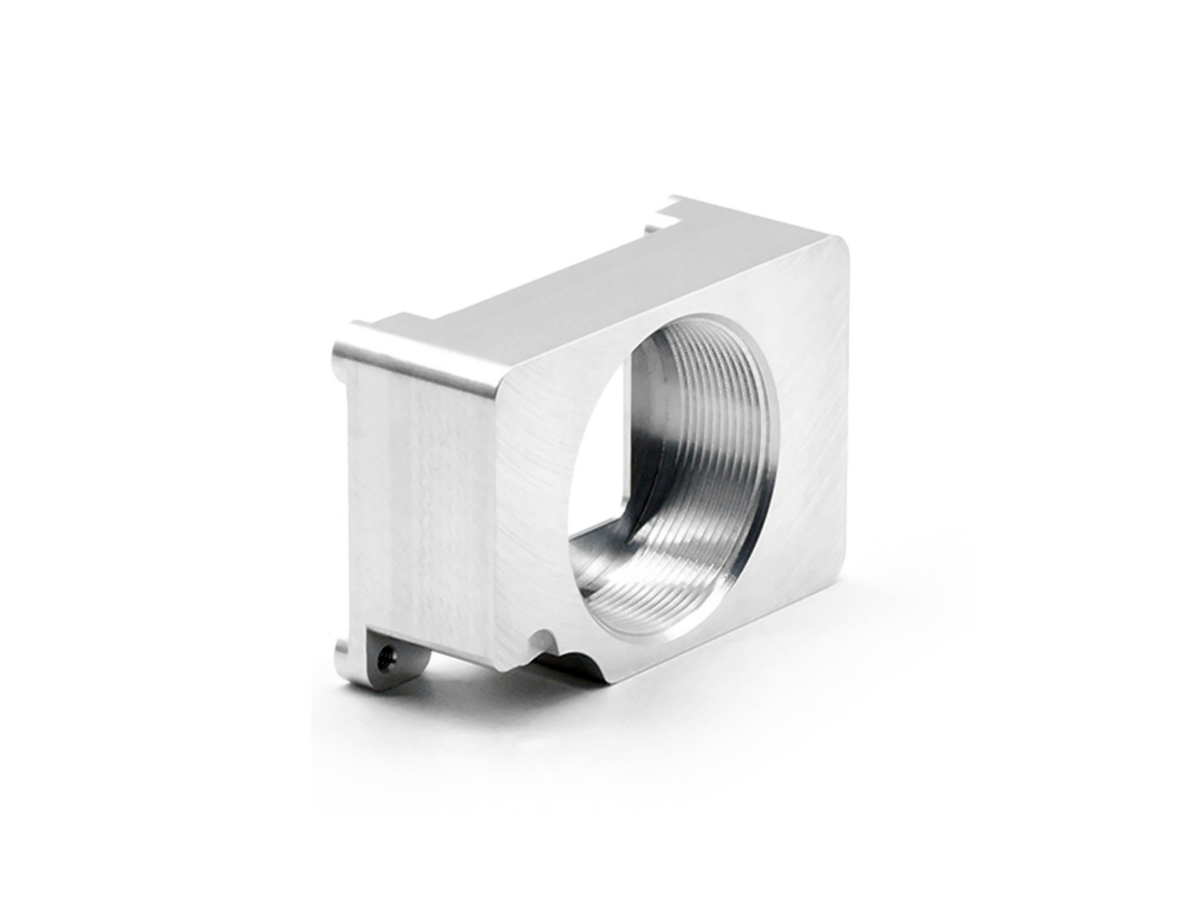

Industries such as automotive, industrial equipment, and consumer products often require small batches of precision components with superior dimensional accuracy, excellent machinability, and cost-effectiveness. Among various materials, 12L14 steel—known for its outstanding machinability and dimensional stability—is ideally suited for producing precision shafts, bolts, fasteners, and detailed small parts. This steel provides manufacturers significant advantages in terms of machining speed, finish quality, and reduced production costs in low-volume manufacturing.

By employing advanced CNC machining, manufacturers precisely fabricate 12L14 steel components with high dimensional accuracy, intricate geometries, and exceptional surface quality, significantly improving the functionality and reliability of precision components.

Comprehensive Analysis of 12L14 Steel for Precision Shafts and Bolts

Comparative Performance of 12L14 Steel and Similar Materials

Material | Tensile Strength (MPa) | Yield Strength (MPa) | Machinability | Typical Applications | Advantage |

|---|---|---|---|---|---|

540 | 415 | Excellent | Precision shafts, bolts | Superior machinability, dimensional stability | |

440 | 370 | Excellent | General shafts, pins | Good machinability, weldability | |

570-700 | 310-450 | Very Good | High-strength shafts, gears | Higher strength, moderate machinability | |

400-540 | 300-450 | Excellent | Fasteners, precision parts | Great machinability, cost-effective |

Strategic Material Selection for CNC Machined 12L14 Steel Components

Selecting 12L14 steel for precision CNC machining involves evaluating machinability, dimensional stability, strength requirements, and production cost-efficiency:

Precision shafts, bolts, and fasteners benefit greatly from 12L14 steel due to its exceptional machinability (rated at 170% compared to standard steels) and consistent dimensional accuracy, reducing cycle times and production costs.

For general-purpose shafts and pins requiring moderate strength (tensile strength around 440 MPa) and weldability, 1018 steel provides a suitable alternative.

Components requiring higher tensile strength (up to 700 MPa) and wear resistance, such as heavy-duty shafts or gears, often select 1045 steel.

Precision components and fasteners with similar machinability needs but slightly lower strength requirements frequently choose 1215 steel for cost-effective solutions.

Precision CNC Machining Processes for 12L14 Steel Components

CNC Machining Process Performance Overview

CNC Machining Process | Dimensional Accuracy (mm) | Surface Roughness (Ra μm) | Typical Applications | Key Advantages |

|---|---|---|---|---|

±0.005-0.01 | 0.4-1.6 | Shafts, bolts, pins | Excellent rotational accuracy | |

±0.005-0.02 | 0.4-3.2 | Complex bolt heads, custom shafts | Versatile, intricate detailing | |

±0.01-0.02 | 1.6-3.2 | Precision holes, tapped holes | Accurate hole alignment | |

±0.003-0.01 | 0.2-0.6 | Complex precision components | Ultra-precise geometries |

Optimizing CNC Machining Processes for 12L14 Steel Precision Components

Choosing the optimal CNC machining process for 12L14 steel components involves assessing component geometry, dimensional accuracy, and surface quality:

Precision shafts, bolts, and cylindrical components requiring tight rotational tolerances (±0.005 mm) and fine surface finishes (Ra ≤1.6 µm) benefit significantly from CNC Turning Service.

Bolts, fasteners, and shafts with detailed heads or custom geometries requiring dimensional accuracy of ±0.005 mm utilize CNC Milling Service for versatile and precise feature creation.

Components demanding accurately placed drilled or tapped holes within tolerances of ±0.01 mm employ CNC Drilling Service, ensuring proper assembly alignment.

Highly complex precision components and intricate geometries needing ultra-tight tolerances (±0.003 mm) and superior surface finishes (Ra ≤0.6 µm) leverage Multi-Axis CNC Machining Service for maximum accuracy.

Advanced Surface Treatments to Enhance 12L14 Steel Components

Surface Treatment Performance and Suitability

Treatment Method | Corrosion Resistance | Wear Resistance | Industrial Suitability | Typical Applications | Key Features |

|---|---|---|---|---|---|

Excellent (>1500 hrs ASTM B117) | High (HV500-700) | Excellent | Bolts, precision shafts | Enhanced durability, corrosion protection | |

Good | Moderate | Excellent | Fasteners, hardware | Economical protection, aesthetic | |

Excellent (>1500 hrs ASTM B117) | High | Excellent | Structural fasteners, precision brackets | Durable and attractive finish | |

Very Good (>1000 hrs ASTM B117) | Moderate | Excellent | Small precision components | Improved corrosion resistance, clean finish |

Strategic Surface Treatment Selection for CNC Machined 12L14 Steel

Choosing surface treatments involves corrosion resistance, wear requirements, and aesthetic considerations:

Precision shafts, bolts, and critical fasteners benefit from Electroplating, providing excellent corrosion resistance (≥1500 hours ASTM B117) and hardness (500-700 HV).

General fasteners and hardware components requiring economical protection and aesthetic appeal use Black Oxide Coating.

Structural fasteners, visible brackets, and fittings needing robust corrosion protection and durable finishes select Powder Coating.

Precision small components requiring moderate corrosion protection and a clean finish utilize Passivation to improve surface purity and extend life.

Rigorous Quality Assurance for CNC Machined 12L14 Steel Components

Detailed Quality Control Practices

Quality assurance processes for CNC machined 12L14 steel involve:

Dimensional Inspection: Verification using Coordinate Measuring Machines (CMM) for tolerances (±0.003 mm to ±0.01 mm).

Surface Finish Testing: Profilometers measure Ra values (0.2-3.2 µm), ensuring specified quality standards.

Mechanical Property Testing: The tests of ASTM-standard tensile (ASTM E8), yield, and hardness (Rockwell B/C) validate mechanical consistency.

Corrosion Resistance Testing: ASTM B117 salt spray testing ensures protection meets industry standards (≥1000 hours).

Non-Destructive Testing (NDT): Ultrasonic and magnetic particle inspections detect defects to ensure component integrity.

Comprehensive Documentation: ISO 9001-compliant documentation ensures traceability and adherence to strict standards.

Key Applications of CNC Machined 12L14 Steel Components

Precision shafts and pins.

High-accuracy bolts and fasteners.

Automotive and industrial precision fittings.

Small-batch precision hardware.

Related FAQs:

Why select 12L14 steel for precision CNC machining applications?

What CNC machining methods are best suited for 12L14 steel components?

Which surface treatments effectively protect CNC machined 12L14 steel parts?

How does CNC machining enhance dimensional accuracy of 12L14 steel shafts and bolts?

What industries typically benefit from low-volume CNC machining of 12L14 steel components?