Carbon Steel Precision Parts: Boosting Efficiency in Industrial Equipment

Enhancing Industrial Performance with Carbon Steel

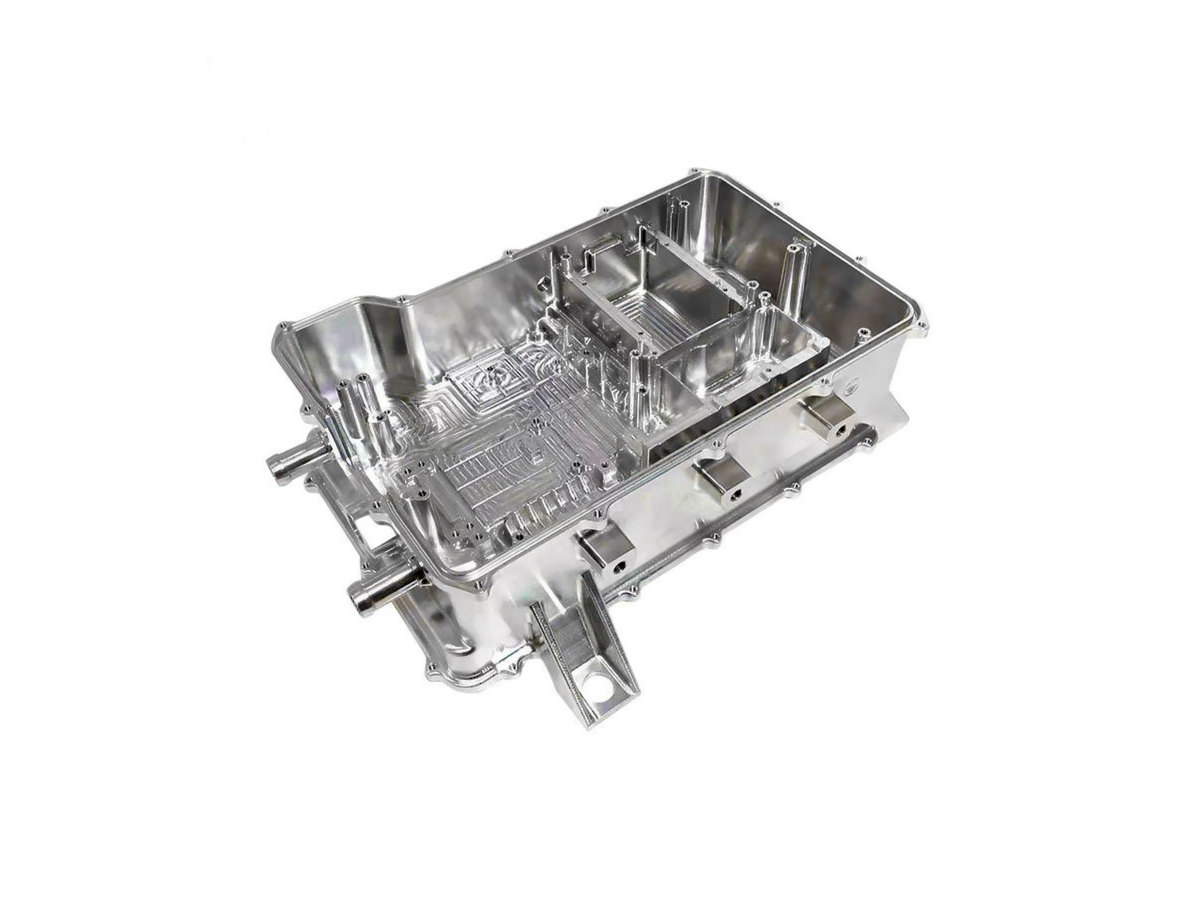

The industrial equipment sector requires materials that balance strength, machinability, and cost-effectiveness. Carbon steel, used in 60% of heavy machinery components, delivers tensile strengths up to 1,200 MPa at 50% lower cost than alloy steels. Precision CNC machining services enable gears, shafts, and hydraulic components with ±0.01mm tolerances, meeting ISO 2768-f standards for industrial applications.

As automation accelerates, manufacturers leverage multi-axis CNC machining to produce complex carbon steel parts like robotic arm linkages and conveyor sprockets. Advanced processes reduce production cycles by 30-40% while achieving Ra 0.8μm surface finishes critical for wear resistance.

Material Selection: Carbon Steel Grades for Industrial Demands

Material | Key Metrics | Industrial Applications | Limitations |

|---|---|---|---|

440 MPa UTS, 15% elongation | Structural frames, bushings | Requires coating for corrosion protection | |

585 MPa UTS, 12% elongation | Gears, axles | Limited impact resistance at low temps | |

950 MPa UTS (QT condition) | Hydraulic cylinders, dies | Requires pre-heat treatment | |

540 MPa UTS, 0.3% lead content | Fasteners, fittings | Unsuitable for welding applications |

Material Selection Protocol

High-Wear Components

Technical Basis: 4140 steel hardened to HRC 28-32 provides optimal toughness for mining equipment gears. Post-machining induction hardening achieves a surface hardness of HRC 55-60.

Validation: Meets AGMA 2001-D04 gear tooth fatigue standards for 50,000+ operating hours.

Cost-Sensitive Assemblies

Strategy: 1018 steel with zinc plating reduces material costs by 40% vs. stainless steel for conveyor brackets.

High-Speed Production

Efficiency Focus: 12L14 steel enables 90 m/min machining speeds for mass-produced fasteners, cutting cycle times by 25%.

CNC Machining Process Optimization

Process | Technical Specifications | Industrial Applications | Advantages |

|---|---|---|---|

±0.005mm roundness, 3,000 RPM | Pump shafts, valve bodies | Completes OD/ID features in one setup | |

8mm DOC, 0.15mm/tooth feed | Mold base plates | Reduces roughing time by 50% | |

30xD depth, 0.02mm straightness | Hydraulic manifold channels | Eliminates gun drilling requirements | |

ISO metric threads, 4,000 RPM | Fastener production | Improves thread strength by 30% |

Process Strategy for Gear Manufacturing

Soft Machining

Operation: Rough-turn 1045 steel blanks to 0.5mm oversize using CBN inserts at 250 m/min.

Heat Treatment

Protocol: 850°C oil quenching + 550°C tempering to achieve HRC 28-32 core hardness.

Hard Machining

Technology: PCBN tooling finishes gear teeth to AGMA 12 accuracy with Ra 0.8μm.

Surface Enhancement

Coating: Ferritic nitrocarburizing creates a 20μm diffusion layer with >800 HV surface hardness.

Surface Engineering: Industrial-Grade Protection

Treatment | Technical Parameters | Industrial Benefits | Standards |

|---|---|---|---|

8-12μm thickness, 500h salt spray | Cost-effective corrosion barrier | ASTM B633 | |

1-2μm Fe₃O₄ layer, oil-impregnated | Reduces light reflection in machinery | MIL-DTL-13924 | |

50μm thickness, HRC 50 | Wear resistance for sliding parts | AMS 2404 | |

60-120μm epoxy-polyester hybrid | Chemical resistance in washdown areas | AAMA 2604 |

Coating Selection Logic

Outdoor Equipment

Solution: Hot-dip galvanizing (85μm) protects structural steel from ISO 9223 C4 corrosive environments.

Food Processing Machinery

Regulatory Compliance: Electropolished 304 stainless cladding over carbon steel meets FDA 21 CFR 117 hygiene requirements.

Quality Control: Industrial Validation

Stage | Critical Parameters | Methodology | Equipment | Standards |

|---|---|---|---|---|

Material Certification | C: 0.18-0.23%, Mn: 0.60-0.90% | OES analysis | SPECTROMAXx | ASTM A29 |

Dimensional Inspection | ±0.025mm profile tolerance | Laser scanning | FARO Edge ScanArm | ISO 10360-5 |

Hardness Testing | HRC 28-32 (case/core) | Rockwell superficial tester | Wilson 574RS | ASTM E18 |

Fatigue Testing | 10⁶ cycles @ 80% yield strength | Resonance fatigue system | Rumul Cracktronic | ISO 12107 |

Certifications:

ISO 9001:2015 with CPK >1.67 for critical dimensions.

ASME B46.1 surface texture compliance.

Industry Applications

Mining Crushers: 4140 steel jaw plates with HRC 55 surface hardness.

Hydraulic Systems: 1045 steel pump bodies achieving 0.01mm bore concentricity.

Conveyor Systems: 1018 steel rollers with zinc-nickel coating for salt mine operations.

Conclusion

Precision carbon steel machining services reduce industrial equipment manufacturing costs by 25-40% while maintaining ISO 9001 compliance. Integrated one-stop solutions accelerate production timelines by 30% for high-volume components.

FAQ

Why choose 4140 steel over 1045 for heavy machinery?

How does electroless nickel improve wear resistance?

What certifications ensure carbon steel part quality?

Can carbon steel replace cast iron in industrial applications?

How to prevent rust on outdoor carbon steel components?