Ti-6Al-2Sn-4Zr-2Mo (Grade 4)

Introduction to Ti-6Al-2Sn-4Zr-2Mo (Grade 4)

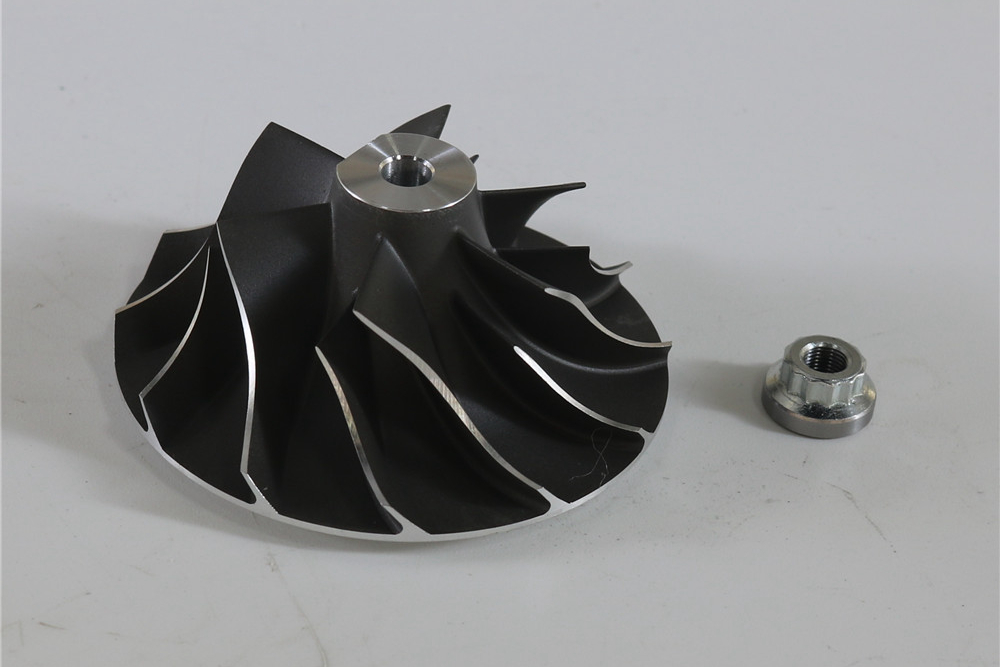

Ti-6Al-2Sn-4Zr-2Mo, also known as Grade 4 titanium in the aerospace alloy family, is a near-alpha titanium alloy designed for excellent high-temperature strength, thermal stability, and corrosion resistance. This alloy is widely used in gas turbines, airframes, and other applications requiring long-term performance under elevated temperatures.

Its reliable mechanical stability and oxidation resistance make it a preferred material for high-spec CNC machined titanium parts. For applications demanding tight tolerances and dimensional control in extreme environments, manufacturers depend on advanced CNC machining services to produce precision components from Grade 4 titanium.

Chemical, Physical, and Mechanical Properties of Ti-6Al-2Sn-4Zr-2Mo (Grade 4)

Chemical Composition (Typical)

Element | Composition Range (wt.%) | Key Role |

|---|---|---|

Titanium (Ti) | Balance | Base element with corrosion and thermal resistance |

Aluminum (Al) | 5.5–6.5 | Alpha stabilizer for high-temperature strength |

Tin (Sn) | 1.8–2.5 | Improves creep resistance |

Zirconium (Zr) | 3.6–4.5 | Enhances oxidation resistance and strength |

Molybdenum (Mo) | 1.8–2.5 | Beta stabilizer that increases hardenability |

Silicon (Si) | ≤0.25 | Strengthens matrix and enhances creep resistance |

Oxygen (O) | ≤0.15 | Strengthens but affects ductility |

Iron (Fe) | ≤0.30 | Residual element |

Hydrogen (H) | ≤0.015 | Controlled to avoid embrittlement |

Physical Properties

Property | Value (Typical) | Test Standard/Condition |

|---|---|---|

Density | 4.55 g/cm³ | ASTM B311 |

Melting Range | 1600–1660°C | ASTM E1268 |

Thermal Conductivity | 6.8 W/m·K at 100°C | ASTM E1225 |

Electrical Resistivity | 1.62 µΩ·m at 20°C | ASTM B193 |

Thermal Expansion | 8.5 µm/m·°C | ASTM E228 |

Specific Heat Capacity | 570 J/kg·K at 20°C | ASTM E1269 |

Elastic Modulus | 108 GPa | ASTM E111 |

Mechanical Properties (Annealed Condition)

Property | Value (Typical) | Test Standard |

|---|---|---|

Tensile Strength | 860–980 MPa | ASTM E8/E8M |

Yield Strength (0.2%) | 790–900 MPa | ASTM E8/E8M |

Elongation | ≥10% | ASTM E8/E8M |

Hardness | 300–340 HB | ASTM E10 |

Creep Resistance | Excellent | ASTM E139 |

Fatigue Resistance | High | ASTM E466 |

Key Characteristics of Ti-6Al-2Sn-4Zr-2Mo (Grade 4)

Elevated Temperature Strength: Grade 4 maintains high strength and creep resistance up to 500°C, making it suitable for gas turbine engines, airframes, and heat shields.

Excellent Oxidation Resistance: The addition of Zr and Sn supports the formation of a stable oxide layer, ensuring long-term durability in high-temperature and oxygen-rich environments.

Thermal Fatigue Resistance: Its alloying balance provides stability under cyclic heating and cooling, critical for aerospace and power generation components.

Superior Weldability and Stability: Despite being a near-alpha alloy, it is readily weldable and maintains phase balance after heat cycles, ideal for high-pressure assemblies.

CNC Machining Challenges and Solutions for Grade 4 Titanium

Machining Challenges

High Work Hardening Rate: Grade 4 tends to work harden during tool contact, requiring optimized chip load and tool sharpness to avoid surface distortion.

Low Thermal Conductivity: With only 6.8 W/m·K conductivity, the alloy retains heat at the tool-chip interface, reducing tool life and increasing the chance of thermal deformation.

Tool Wear and Galling: Aggressive oxide formation and beta-rich zones accelerate wear and promote chip adhesion to tools, impacting surface finish.

Elastic Recovery: With a modulus of 108 GPa, the alloy exhibits measurable spring back, especially in thin-walled parts and finishing operations.

Optimized Machining Strategies

Tool Selection

Parameter | Recommendation | Rationale |

|---|---|---|

Tool Material | Fine-grain carbide or ceramic inserts | High strength and heat resistance |

Coating | AlTiN or TiSiN (3–5 µm) | Reduces BUE and increases tool life |

Geometry | Sharp edge, high rake angle | Lowers cutting force and thermal input |

Cutting Speed | 25–60 m/min | Prevents overheating and surface hardening |

Feed Rate | 0.10–0.25 mm/rev | Supports chip formation and avoids glazing |

Coolant | Emulsion coolant, ≥100 bar | Provides effective cooling and chip flushing |

Ti-6Al-2Sn-4Zr-2Mo (Grade 4) Cutting Parameters (ISO 3685 Compliance)

Operation | Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) | Coolant Pressure (bar) |

|---|---|---|---|---|

Roughing | 20–30 | 0.15–0.20 | 2.0–3.0 | 80–100 (Through-tool) |

Finishing | 45–65 | 0.05–0.10 | 0.2–0.5 | 100–150 |

Surface Treatment for Grade 4 Titanium Parts

Hot Isostatic Pressing (HIP) densifies internal microvoids and increases fatigue life, especially for flight-critical components.

Heat Treatment involves 600–675°C aging to enhance creep resistance and dimensional stability in turbine hardware.

Superalloy Welding ensures full-strength fusion welds for aerospace and propulsion assemblies using compatible filler rods.

Thermal Barrier Coating (TBC) adds oxidation and thermal fatigue protection for components in jet engines and high-heat reactors.

CNC Machining supports ±0.01 mm tolerances and is ideal for flight hardware, high-performance flanges, and brackets.

Electrical Discharge Machining (EDM) enables precise features like orifices and deep pockets in heat-treated parts.

Deep Hole Drilling provides bore depths with L/D > 30:1 and surface finish Ra ≤ 1.6 µm in structural and cooling components.

Material Testing includes tensile, creep rupture, SEM microstructure, and ultrasonic NDT to aerospace QA standards.

Material Testing and Analysis

Material validation for Grade 4 includes high-temperature tensile testing, creep rupture evaluation, microhardness, XRD, and metallographic analysis, ensuring compliance with aerospace and nuclear standards.

Industry Applications of Ti-6Al-2Sn-4Zr-2Mo (Grade 4)

Aerospace: Engine casings, afterburner components, and nozzle hardware operating above 400°C.

Power Generation: Gas turbine blades, exhaust ducting, and high-pressure combustor elements.

Defense Systems: Structural aerospace connectors and propulsion system liners requiring temperature endurance.

Industrial Equipment: Heat exchangers and high-pressure seals in corrosive and thermal cycling environments.

Aerospace Fasteners: Bolts and flange systems for high-cycle fatigue and elevated thermal load regions.