Which plastics provide the best surface finish after milling?

Which Plastics Provide the Best Surface Finish After Milling?

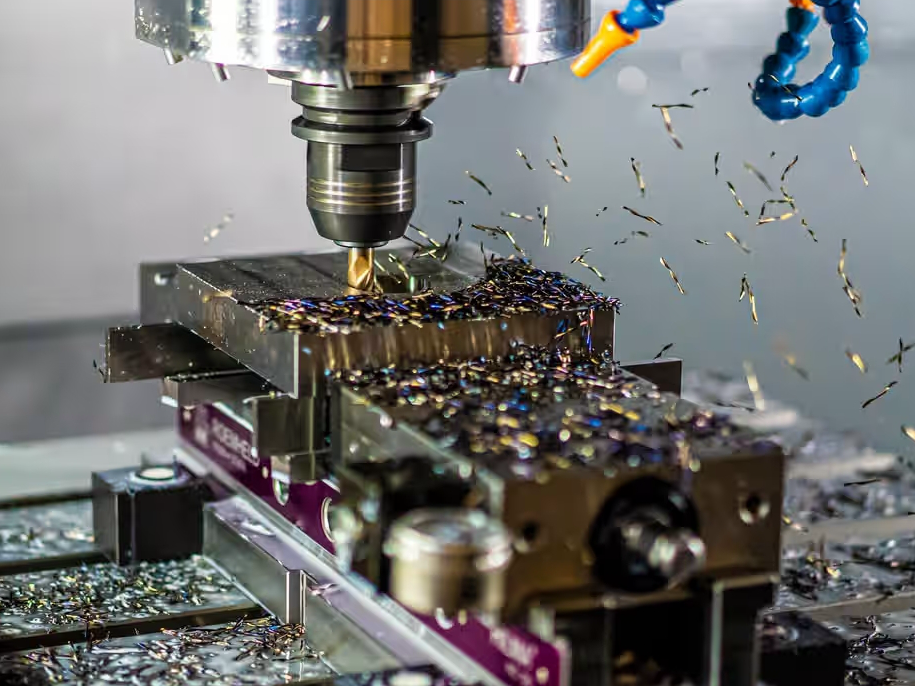

In CNC plastic machining, surface finish quality is influenced by both material properties and toolpath strategy. At Neway, we select plastics for high-end visual and functional parts based on resin structure, hardness, and melt behavior. The following plastics consistently deliver superior surface finishes straight off the mill—often requiring little or no post-processing.

Top Plastics for Excellent Surface Finish

Material | Typical Surface Finish (Ra) | Applications |

|---|---|---|

POM (Acetal) | 0.2 – 0.5 µm | Gears, valves, precision wear parts |

PEEK | 0.3 – 0.6 µm | Medical devices, aerospace, insulators |

PMMA (Acrylic) | 0.2 – 0.4 µm (clear polish) | Transparent covers, optical housings |

PC (Polycarbonate) | 0.4 – 0.8 µm | Impact-resistant lenses, electronic enclosures |

ABS | 0.8 – 1.2 µm | Consumer prototypes, enclosures |

1. POM (Acetal) – Best All-Around Surface Finish

POM is naturally self-lubricating and machines with clean edges and minimal burr. It provides a glossy, smooth surface even at high feed rates, making it ideal for moving parts or assemblies requiring tight mating.

2. PEEK – Premium Finish for High-Performance Parts

PEEK maintains exceptional finish and dimensional stability under aggressive cutting conditions. It can achieve Ra < 0.6 µm with proper tool geometry. Used in aerospace, medical implants, and high-voltage insulators where both strength and finish matter.

3. PMMA (Acrylic) – Clear Machined Surfaces

PMMA is ideal for transparent components like viewports and light guides. With low feed, sharp tools, and proper chip evacuation, it produces a clear or semi-clear machined surface that can be flame or vapor polished for full optical clarity.

4. Polycarbonate (PC) – Tough and Smooth

Polycarbonate is more impact-resistant than acrylic, though slightly harder to polish optically. Still, it provides a smooth surface suitable for enclosures and covers. Proper fixturing and sharp tools help avoid melting and edge degradation.

5. ABS – Good for Cost-Effective Aesthetic Prototypes

ABS offers reasonable surface finish (Ra ~1.0 µm), though slightly grainier than others. It's easy to machine and polish, making it suitable for painted or post-finished cosmetic parts.

Machining Tips for Better Finish

Use high-rake, polished cutters

Maintain consistent chip load (0.1–0.25 mm/tooth)

Avoid coolant on hygroscopic plastics; use dry air blast instead

Optimize step-over to <20% of tool diameter for smooth passes

Manufacturing Services You May Need

Neway offers high-precision plastic CNC machining services for applications where surface finish is critical. We specialize in milling POM, PEEK, PMMA, and PC components with Ra < 0.4 µm for functional and visual applications.