What’s the cost difference between milling plastic and metal?

What’s the Cost Difference Between Milling Plastic and Metal?

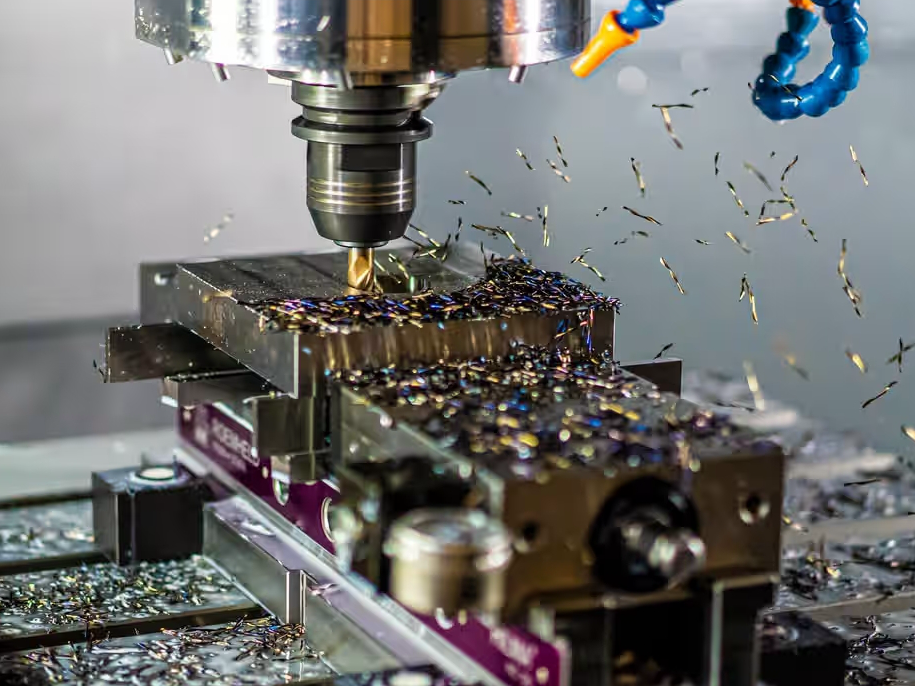

CNC milling plastic parts is generally 30–60% cheaper than milling metal parts. This cost difference comes from shorter machining times, lower tool wear, and easier fixturing. At Neway, we help clients select materials that balance mechanical performance with manufacturing efficiency—especially during prototyping or low-volume runs.

Key Cost Factors: Plastic vs. Metal

Factor | Plastic Milling | Metal Milling |

|---|---|---|

Material Cost | $2–$10/kg (ABS, POM, PC) | $5–$40/kg (Aluminum, Stainless Steel) |

Machining Time | Shorter (30–50% less cycle time) | Longer due to higher hardness |

Tool Wear | Minimal (tools last longer) | High, especially with stainless/superalloy |

Surface Finish | Achievable quickly without post-polish | May need extra polishing or coating |

Setup/Fixturing | Easier; softer clamping forces | Needs rigid setup to avoid deflection |

Real-World Example: 100 × 80 × 10 mm Bracket

Material | Machining Time | Tool Cost Impact | Total Cost per Part |

|---|---|---|---|

ABS Plastic | 12 min | Low | $8 – $15 |

Aluminum 6061 | 20 min | Medium | $18 – $30 |

Stainless 304 | 35 min | High | $30 – $50 |

Plastics like ABS or POM allow faster feeds and speeds, reducing hourly cost impact. Metals like aluminum still offer good value for functional prototypes but require more energy and tool changes.

When Metal May Be More Cost-Effective

In high-volume production, metal parts may benefit from:

Tighter tolerances and thermal stability

Mechanical strength for load-bearing functions

Surface treatments such as anodizing or plating not suitable for most plastics

Thus, metal becomes cost-effective when part durability and performance outweigh machining cost.

Manufacturing Services You May Need

Neway offers full-spectrum CNC machining services for both plastics and metals, including ABS, POM, aluminum 6061, and stainless steel 304. We help you choose the right material for your budget and performance needs.