5-Axis CNC Machining of SUS 316L Press-Fit Connectors for Bosch Fluid Systems

Project Background: High-Integrity Connectors for Automotive Pressure Systems

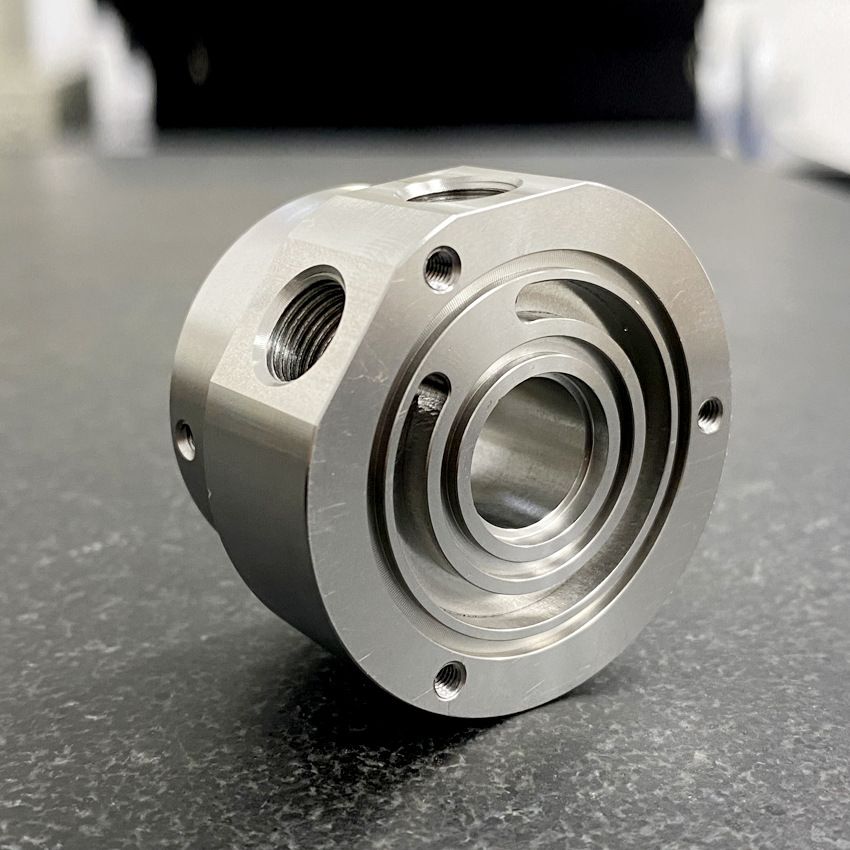

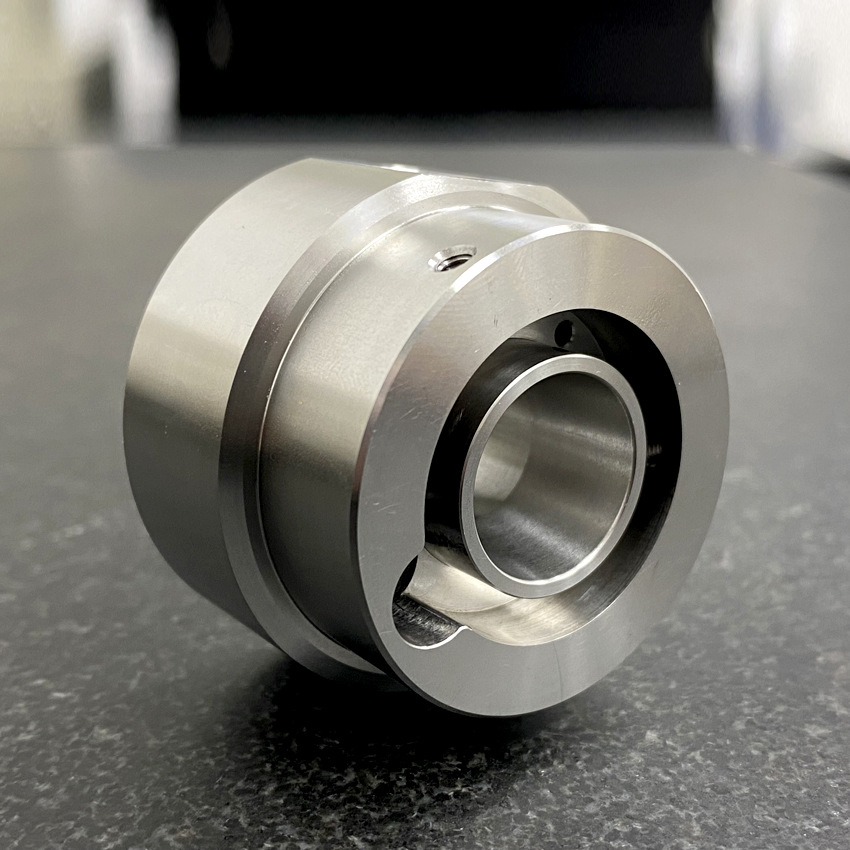

Bosch required a corrosion-resistant, dimensionally stable press-fit connector for use in advanced fluid delivery systems in automotive applications. The part needed to meet strict pressure-sealing requirements, thread precision, and long-term corrosion resistance. Neway was selected to supply complete manufacturing—starting from rough turning through high-precision 5-axis machining and finishing.

Why SUS 316L Stainless Steel Was Selected

SUS 316L is widely used in fluid systems due to its enhanced corrosion resistance, strength, and compatibility with surface finishing.

Property | Value |

|---|---|

Yield Strength | ≥170 MPa |

Elongation | ≥40% |

Corrosion Resistance | Excellent (chloride environments) |

Surface Finish Suitability | Ideal for blasting and marking |

Its low carbon content makes it ideal for welding and dimensional stability in automotive pressure fittings. Learn more about 316L Stainless Steel CNC Machining.

CNC Machining Process Overview

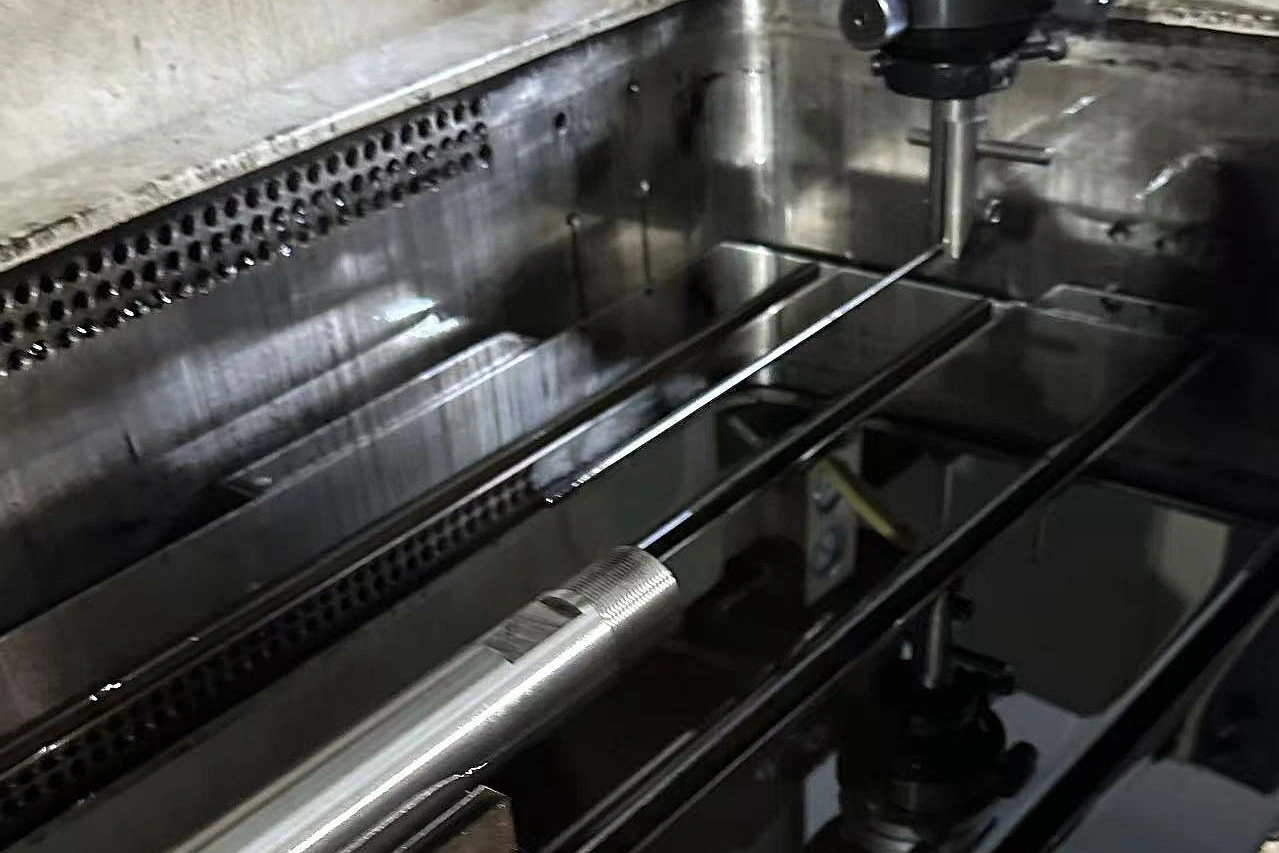

Turning for Rough Shaping

The part’s cylindrical blank was initially prepared using CNC turning, which produced accurate diameters for threads, press-fits, and sealing surfaces.

5-Axis CNC Precision Machining

Complex undercuts, angled threads, and multi-surface sealing features were finished using 5-axis CNC machining. This allowed single-setup machining with ±0.01 mm tolerance across thread faces and internal bores.

Surface Treatment and Branding

The connector required surface durability and traceability. Neway applied a three-stage finishing sequence:

Sandblasting: Delivered a consistent satin finish (~Ra 1.2 μm) and removed minor tool marks

Anodizing: Custom process adapted for stainless steel using passivation-equivalent clear oxide protection

Laser Marking: Serialized part IDs and Bosch logos were applied with high-resolution, corrosion-resistant laser engraving

Quality Control & Testing

Thread Gauge Testing: All press-fit threads verified with calibrated Go/No-Go gauges

Leak Tightness Inspection: Dimensional control of sealing faces confirmed with CMM and contact profilometry

Surface Integrity: Blasted and anodized parts passed salt spray corrosion resistance per ASTM B117 for >240 hours

Production Result

Neway successfully produced a 3,000-piece batch with zero sealing failures and full traceability across all units. Bosch reported excellent threading consistency, reliable press-fit tolerances, and consistent cosmetic quality across batches. The components passed all hydraulic and vibration system qualification tests.

Why Neway for CNC Machined Press-Fit Connector Components

Stainless Steel Machining Service: Enables accurate production of angled sealing faces and multi-axis threads

CNC Turning Service: Ideal for concentric tolerance control and diameter transitions

One-Stop Manufacturing Service: Fully integrated machining and finishing improve consistency and traceability

FAQs

What thread tolerances can be achieved on SUS 316L connectors with CNC machining?

How does 316L perform under salt spray and vibration testing?

Can stainless steel parts be anodized, or is passivation preferred?

What are the benefits of 5-axis machining in angled press-fit sealing zones?

How is laser marking applied without damaging the corrosion-resistant surface?