Stronger CNC Machined Stainless Steel Parts: Typical Surface Treatments

Introduction

Stainless steel is preferred in CNC machining due to its superior corrosion resistance, strength, and clean surface finish. Yet, when used in aggressive environments or demanding applications, CNC machined stainless steel parts often require post-processing surface treatments to improve durability, wear resistance, and visual appeal.

Surface treatments such as passivation, polishing, and advanced coatings preserve the anti-corrosive nature of stainless steel and extend the service life of critical components in industries like medical, aerospace, food processing, and marine. This blog introduces nine of the most effective surface treatments for stainless steel CNC components.

Surface Treatment Technologies for Stainless Steel Components

Scientific Principles & Industrial Standards

Definition: Surface treatments for stainless steel enhance its existing properties—corrosion resistance, surface hardness, and appearance—through mechanical finishing or electrochemical and chemical processing without altering the alloy’s core integrity.

Governing Standards:

ASTM A967 / A380: Passivation and cleaning of stainless steel surfaces.

ASTM B912: Electropolishing and passivation of stainless alloys.

ISO 9227: Corrosion resistance testing (salt spray).

Process Function and Cases

Performance Dimension | Technical Parameters | Application Cases |

|---|---|---|

Corrosion Resistance | - Passivation: improves oxide layer density - Powder coating resists >1,000 hrs salt spray - Teflon coating withstands pH 1–14, 260°C | Food processing tools, medical instruments, marine fasteners |

Wear Resistance | - Chrome hardness: HV 800–1000 - PVD coating: HV 2000–3000 - Teflon friction: 0.05–0.20 | Surgical tools, robotic joints, bearing sleeves |

Surface Aesthetics | - Polishing to Ra ≤ 0.2 µm - Brushing with #320–#600 grit - Black oxide adds matte black finish | Decorative hardware, casings, kitchen appliances |

Electrical/Functional Coating | - Electroplated Ni: 5–25 µm - Passivation: dimensional stability with no coating - Chrome: shiny finish + hydrophobic | Enclosures, terminals, electronic housings |

Surface Treatment Process Classification

Technical Specification Matrix

Treatment Type | Key Parameters & Metrics | Advantages | Limitations |

|---|---|---|---|

- Coating: 5–25 µm - Ni, Ag, Cr used for function and aesthetics | - Improved conductivity and corrosion resistance - Smooth finish | - Not always needed on stainless—careful material match required | |

- Surface roughness Ra ≤ 0.2 µm - Mechanical or electrochemical | - Improves cleanliness and shine - Ideal for sterile/visual applications | - Needs sealing or frequent maintenance in harsh environments | |

- Abrasive: #320–#600 grit - Satin or matte finish | - Anti-glare, fingerprint-resistant surface - Popular for exposed parts | - May trap contaminants without sealing | |

- Thickness: 1–5 µm - Hardness: HV 2000–3000 | - Ultra-hard, decorative, biocompatible - Thin and uniform | - High equipment cost | |

- Nitric or citric acid bath - Duration: 20–30 min @ 50–60°C | - Restores protective oxide layer - No dimension change | - Not suitable for low-chromium alloys | |

- Coating: 60–120 µm - Cure: 190–200°C for 15–25 min | - Durable color and corrosion barrier - Wide aesthetic range | - Reduces conductivity; thicker finish | |

- Friction: 0.05–0.20 - Operating temp: –200°C to +260°C | - Chemical inertness - Non-stick, low-wear surface | - May require primer layer; reduces dimensional precision | |

- Thickness: 0.5–2.5 µm - Surface hardness HV 800–1000 | - Bright, corrosion-resistant finish - Wear-resistant | - Uses hexavalent chromium—regulated | |

- Oxide film ~1 µm - Matte black appearance | - Minimal dimensional impact - Adds mild corrosion resistance | - Needs oil sealant for optimal durability |

Selection Criteria & Optimization Guidelines

Electroplating

Selection Criteria: Used for functional or decorative applications like medical housings, connectors, or consumer-grade fixtures where corrosion and conductivity are priorities.

Optimization Guidelines:

Maintain bath temp at 50–60°C; use pre-strike layer for adhesion.

Use nickel or gold over stainless grades with high chromium.

Apply trivalent chrome for eco-friendly finishes.

Polishing

Selection Criteria: Ideal for components requiring easy sterilization and aesthetics such as medical, food-grade, or luxury consumer products.

Optimization Guidelines:

Use multi-stage abrasive progression to achieve Ra ≤ 0.1 µm.

Employ electropolishing for hard-to-reach geometries.

Seal the polished surface with an oxide layer or anti-fingerprint coatings.

Brushing

Selection Criteria: Common in kitchen hardware, elevator panels, and machinery casings where a muted look is preferred over gloss.

Optimization Guidelines:

Use unidirectional brushing motion.

Finish with a clear protective coating to resist oils and oxidation.

Combine with passivation to restore the oxide layer.

PVD Coating

Selection Criteria: Suited for high-end consumer parts, surgical tools, and fasteners needing hard, decorative, and biocompatible surfaces.

Optimization Guidelines:

Pre-clean to <10° contact angle and preheat to 150–200°C.

Maintain chamber pressure <1×10⁻² Pa for optimal deposition.

Select TiN, CrN, or DLC for tailored hardness/color.

Passivation

Selection Criteria: Essential for any machined stainless steel component in corrosive or cleanroom environments—especially post-machining.

Optimization Guidelines:

Use 10–20% citric or nitric solution, 50–60°C for 20 min.

Test post-passivation with water break or peroxyl methods.

Ensure full removal of free iron particles via pre-cleaning.

Powder Coating

Selection Criteria: Used on covers, frames, or non-functional surfaces for both corrosion protection and visual identity.

Optimization Guidelines:

Electrostatically (60–90 kV) is applied to grounded stainless steel.

Pre-treat the surface with phosphate coating or sandblasting.

Cure at 190°C for 15–20 minutes (ASTM D2454 compliance).

Teflon Coating

Selection Criteria: Ideal for valves, seals, and food contact components exposed to high heat or aggressive chemicals.

Optimization Guidelines:

Grit blast to Ra ~1.0 µm before primer coat.

Apply 20–30 µm per layer; total thickness <100 µm.

Bake at 370°C (PTFE) or 280°C (FEP).

Chrome Plating

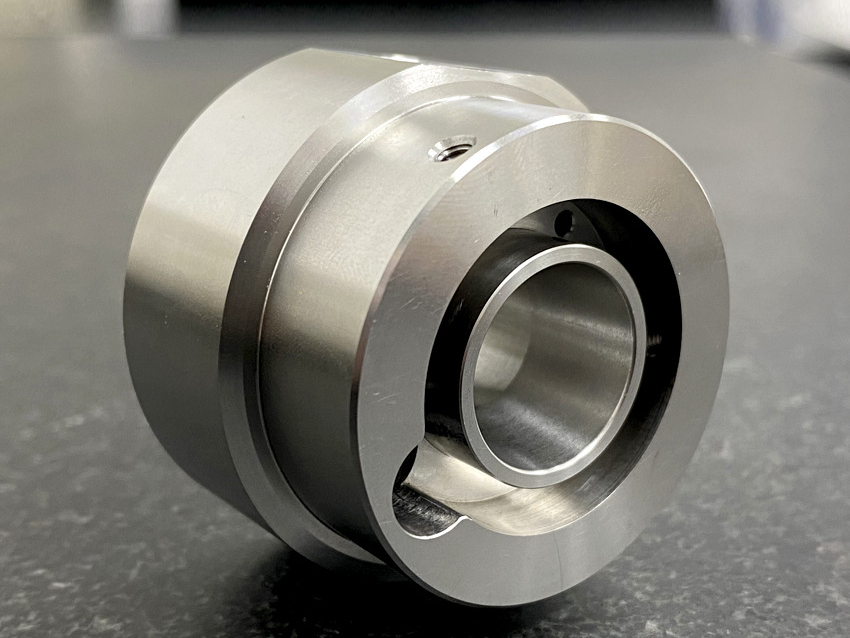

Selection Criteria: Perfect for shafts, pins, and rotating components where high wear resistance and smooth surface are vital.

Optimization Guidelines:

Polish to mirror finish pre-plating (Ra < 0.05 µm).

Plate using 25–30 A/dm² at 50–55°C.

Employ nickel undercoat for adhesion on austenitic grades.

Black Oxide

Selection Criteria: Used for non-critical stainless parts requiring matte finish and basic corrosion protection—common in tool handles and brackets.

Optimization Guidelines:

Clean thoroughly and immerse in 140°C alkaline solution.

Seal with oil or wax for enhanced rust protection.

Validate appearance with visual standard (ASTM D660).

Material-Coating Compatibility Chart

Stainless Steel Grade | Recommended Surface Treatment | Performance Gain | Industrial Validation Data |

|---|---|---|---|

Passivation | Restores oxide layer, improves corrosion resistance | Used in medical and food-grade assemblies | |

Teflon Coating | Withstands acidic/alkaline cleaning cycles | Used in biotech valves and mixing nozzles | |

Polishing + Electropolishing | Smooth finish for friction reduction and hygiene | Used in high-speed dental tools and conveyors | |

PVD Coating | Enhanced hardness and wear protection | Used in bearing races and cutting instruments | |

Chrome Plating | Surface protection and dimensional stability | Used in aerospace actuators and surgical pins |

Comprehensive Process Control and Quality Assurance

Preparation and Quality Standards

Pre-Treatment: Degreasing, descaling, mechanical cleaning, and pickling per treatment type.

Process Control: Strict control of temperature, dwell time, and chemical concentration.

Post-Treatment Testing: Includes coating thickness (ASTM D7091), corrosion resistance (ASTM B117), adhesion (ASTM D3359), and surface finish (Ra via profilometry).

Expert Insights and Common Inquiries

Does stainless steel still benefit from passivation after CNC machining?

Which surface treatment maximizes wear life in rotating applications?

Can black oxide be used on stainless steel for tool-grade parts?

What finishes are best for food-safe stainless steel applications?

How do PVD and chrome plating compare on high-tolerance parts?