Techniques clés de post-traitement pour pièces en titane usinées CNC

Introduction : le post-traitement, clé pour libérer tout le potentiel du titane

Dans la pratique de fabrication de précision de Neway, une leçon reste constante : une pièce en titane de haute qualité n’est jamais « terminée » au dernier passage CNC. Grâce à son excellent rapport résistance/poids, sa résistance à la corrosion et sa biocompatibilité, le titane est utilisé dans de nombreuses applications industrielles hautes performances, notamment dans l’aéronautique, le médical et l’énergie. Mais après l’usinage, chaque surface présente encore des contraintes résiduelles, des micro-défauts, des contaminants incrustés et des couches modifiées qui peuvent compromettre la durée de vie en fatigue, les performances d’étanchéité, la propreté et la fiabilité globale.

C’est pourquoi, dans nos services d’usinage CNC du titane, le post-traitement n’est pas une option facultative, mais une étape centrale, conçue comme partie intégrante de la chaîne de processus. Grâce à la bonne combinaison et au bon enchaînement des opérations de nettoyage, de traitement thermique, de renforcement et d’ingénierie de surface, nous transformons des pièces usinées avec précision en composants prêts à l’emploi qui se comportent exactement comme prévu sur le terrain. Cet article présente les principales technologies de post-traitement que nous utilisons pour exploiter pleinement le potentiel des pièces en titane usinées par CNC.

Nettoyage et préparation de surface : la base de tout bon post-traitement

Dégraissage et décontamination : effacer l’empreinte de l’usinage

Avant tout traitement avancé, la surface doit être parfaitement propre. Nous utilisons des nettoyants alcalins dédiés et des solvants organiques choisis pour éliminer fluides de coupe, huiles, empreintes digitales et résidus d’usinage. Pour les géométries complexes, des systèmes combinant immersion multi-étapes et pulvérisation garantissent le nettoyage de chaque poche, contre-dépouille et canal interne. Cette étape « invisible » est cruciale : un nettoyage insuffisant conduit directement à une mauvaise adhérence, à des revêtements incohérents et à des performances de corrosion instables.

Décapage et activation : créer une surface fraîche et réactive

Le décapage élimine les couches d’oxyde, le métal écrasé et les contaminants incrustés tout en activant la surface du titane pour les traitements suivants. Nous utilisons des systèmes à base d’acide nitrique–fluorhydrique rigoureusement contrôlés, en optimisant concentration, température et temps d’exposition afin de réduire au minimum les risques de sur-attaque et de fragilisation par l’hydrogène. Pour le Ti-6Al-4V (TC4), nous appliquons un contrôle particulièrement strict de la teneur en HF pour préserver l’intégrité du matériau.

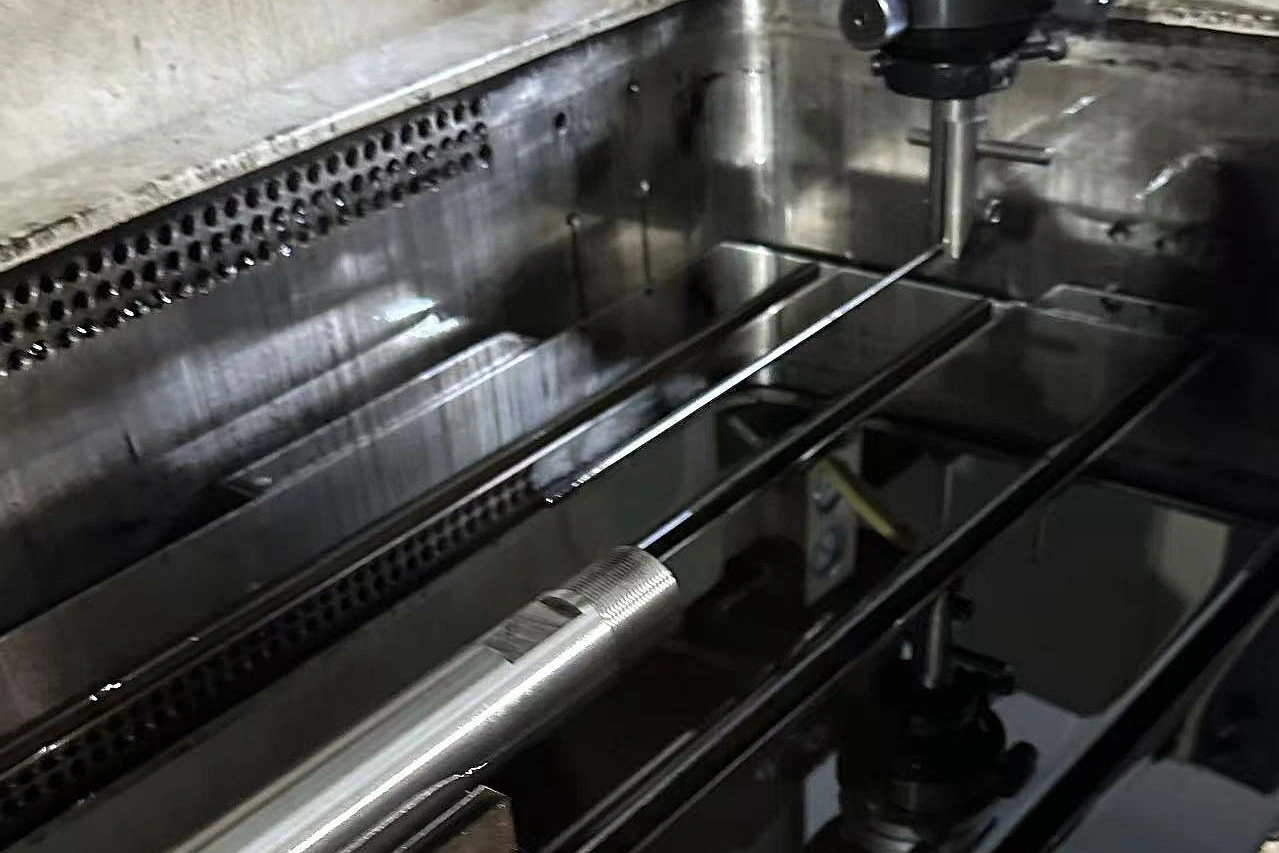

Nettoyage ultrasonique : propreté de précision pour les géométries complexes

Pour les composants présentant des micro-détails, des micro-trous ou des canaux internes, le nettoyage ultrasonique offre une pénétration supérieure. La cavitation dans le bain de nettoyage détache les particules et films inaccessibles par des méthodes conventionnelles. Il s’agit d’une étape clé pour les composants hydrauliques aéronautiques et les implants médicaux, où la propreté est directement liée aux performances et à la conformité réglementaire.

Technologie clé I : anodisation – protection contre la corrosion, dureté et esthétique

Principes et avantages de l’anodisation du titane

Contrairement à l’aluminium, l’anodisation du titane forme un film d’oxyde à base de TiO₂ dense, généralement épais de 0,5 à 5 µm. Cette couche d’oxyde « conçue » améliore fortement la résistance à la corrosion et à l’usure tout en préservant la précision dimensionnelle. En ajustant la composition de l’électrolyte, la tension et la température, nous pouvons adapter les propriétés du film aux besoins spécifiques de votre application.

Anodisation colorée : identité visuelle à signification technique

Les effets d’interférence dans la couche d’oxyde génèrent une large palette de couleurs – or, bleu, violet, vert, etc. – sans utilisation de colorants. Au-delà de l’esthétique, la couleur est corrélée à l’épaisseur de l’oxyde, ce qui en fait un indicateur visuel rapide de la stabilité du procédé et de la qualité. Cette approche est largement utilisée pour les produits grand public haut de gamme, les implants médicaux et les instruments de précision qui exigent à la fois performance et image de marque.

Anodisation à film épais pour applications fortement sollicitées

Pour les environnements exigeants, des procédés spécifiques d’anodisation à film épais permettent d’atteindre des couches d’environ 10 à 25 µm, avec une dureté pouvant monter jusqu’à environ HV800. Ces revêtements sont idéaux pour la visserie et les surfaces de contact aéronautiques, ainsi que pour les assemblages fréquemment montés/démontés nécessitant une résistance renforcée à l’usure sans sacrifier les propriétés de base du titane.

Technologie clé II : grenaillage – augmenter drastiquement la durée de vie en fatigue

Comment le grenaillage introduit des contraintes résiduelles de compression bénéfiques

Le grenaillage bombarde la surface avec des médias projetés à grande vitesse, déformant plastiquement la couche superficielle et créant un champ de contraintes de compression. Cette couche comprimée retarde l’amorçage des fissures et ralentit leur propagation, augmentant considérablement la résistance en fatigue – un enjeu critique pour les trains d’atterrissage, les équerres de structure, les pièces tournantes et les liaisons de sécurité.

Choix du média, contrôle de l’intensité et du taux de couverture

Nous choisissons des billes en acier, céramique ou verre en fonction de l’application, des exigences de propreté et des procédés en aval. Les essais sur témoins Almen et le contrôle de la couverture garantissent une intensité maîtrisée et répétable. Pour les pièces en Ti-6Al-4V ELI (Grade 23) et autres composants sensibles à la contamination, nous utilisons des médias non ferreux pour éviter l’incrustation de fer et préserver la biocompatibilité.

Technologie clé III : traitement thermique – optimisation de la microstructure et des contraintes

Détensionnement : stabiliser les composants en titane de précision

L’usinage génère des contraintes résiduelles pouvant provoquer des déformations en service ou lors d’opérations ultérieures. Grâce à des cycles de détensionnement contrôlés (température et temps de maintien adaptés à chaque alliage), nous réduisons ces contraintes et stabilisons la géométrie, ce qui est particulièrement important pour les carters minces, les bagues, les cadres et les pièces aéronautiques de haute précision.

Traitement thermique sous vide : microstructure propre, sans couche alpha fragilisante

Le titane réagit facilement avec l’oxygène, l’azote et l’hydrogène à haute température. Nos fours sous vide fonctionnent à des niveaux de vide élevés pour prévenir l’oxydation, la formation de couche alpha fragile (« alpha-case ») et la contamination. Pour des alliages comme le Beta C, nous concevons des traitements de mise en solution et de vieillissement qui offrent le compromis résistance–ténacité requis, avec une traçabilité complète.

Technologie clé IV : électropolissage et attaque chimique – ingénierie de surface de précision

Électropolissage : finition miroir et protection passive renforcée

L’électropolissage élimine sélectivement les micro-sommets, produisant des surfaces ultra lisses et brillantes tout en améliorant simultanément la passivation. Pour les applications médicales et hygiéniques, des surfaces plus lisses réduisent l’adhérence bactérienne, améliorent la nettoyabilité et renforcent la résistance à la corrosion – tout en facilitant l’inspection.

Attaque chimique (chemical milling) : amincissement uniforme de géométries complexes

Pour les grands panneaux, les structures nervurées ou les zones où l’usinage mécanique est peu efficace ou risqué pour la stabilité, l’attaque chimique permet un amincissement uniforme et précis des parois via des masquages sélectifs. Cette technique est particulièrement intéressante pour les structures minces aéronautiques, où la réduction de poids et la répartition des contraintes doivent être précisément maîtrisées.

Techniques de soutien : marquage, revêtements et préparation à l’assemblage

Marquage laser pour une traçabilité complète

Nous utilisons des lasers fibrés pour appliquer des identifiants, numéros de série, codes QR et logos nets et permanents, sans dégrader les propriétés mécaniques. Cela permet une traçabilité sur l’ensemble du cycle de vie pour les applications industrielles, aéronautiques et médicales qui exigent un historique documenté pour chaque composant.

Préparation finale des arêtes et traitements spécifiques à l’assemblage

Avant l’expédition ou l’assemblage, nous réalisons des opérations maîtrisées d’ébavurage, d’adoucissement des arêtes et de polissage fin pour éliminer les amorces de fissures et les risques de coupure lors de la manipulation. Le cas échéant, nous appliquons des lubrifiants secs ou des revêtements à faible friction afin de garantir le bon couple de serrage et de prévenir le grippage dans les interfaces titane–titane ou titane–acier.

Synergie de procédés : concevoir la bonne séquence de post-traitement

Les étapes de post-traitement sont interdépendantes et doivent être séquencées intelligemment. Par exemple, le grenaillage intervient généralement après le traitement thermique et non avant. De plus, toutes les opérations d’usinage et d’ébavurage doivent être achevées avant l’anodisation, et un nettoyage est requis avant chaque étape chimique, de revêtement ou thermique. Le marquage et les points de contrôle sont quant à eux positionnés de façon stratégique pour maintenir la traçabilité sans compromettre les états de surface.

Dans le cadre du service intégré « one-stop » de Neway, nous concevons des gammes complètes – usinage, traitement thermique, renforcement et finition de surface – comme un système unique et cohérent, et non comme une série d’opérations isolées. Résultat : des performances prévisibles et une qualité constante, du prototype à la production de série.

Solutions orientées application : adapter le post-traitement à votre secteur

Automobile & sport automobile

Pour les composants automobiles et de compétition, nous privilégions des séquences économiquement optimisées, répétables, centrées sur l’allègement et la tenue en fatigue – en combinant souvent détensionnement, grenaillage et anodisation ou polissage ciblés.

Robotique, applications industrielles et produits grand public

Pour la robotique et les équipements industriels, nous mettons l’accent sur la résistance à l’usure, la fiabilité et des ensembles propres. Pour les produits grand public, l’esthétique premium, le toucher et la stabilité de la couleur après anodisation deviennent des éléments majeurs de conception.

Compétences de Neway en post-traitement et assurance qualité

Neway offre une large gamme de capacités de post-traitement, à la fois en interne et via des partenaires qualifiés et audités – du nettoyage de précision, traitement thermique sous vide, grenaillage, anodisation et passivation, jusqu’à l’électropolissage, l’attaque chimique, les revêtements et le marquage laser. Nos ingénieurs maîtrisent à la fois la métallurgie du titane et les exigences réelles des applications, ce qui nous permet de concevoir des gammes de post-traitement qui améliorent les performances plutôt que de simplement « donner un bel aspect » aux pièces.

Intégrés à nos services de production de masse, nous maintenons un contrôle strict des procédés, de la documentation et de la traçabilité pour des secteurs tels que l’aéronautique, le médical, le pétrole & gaz et les systèmes industriels haut de gamme – en veillant à ce que chaque composant en titane quittant notre usine soit prêt pour sa mission.