Stainless Steel Deep Hole Drilling for Industrial Equipment: A Case Study on Efficiency and Accuracy

Precision for Harsh Farming Environments

Agricultural machinery components face extreme wear from abrasive soils, fertilizers, and moisture. Brass and bronze alloys are critical for hydraulic valves, spray nozzles, and bearing sleeves due to their corrosion resistance and self-lubricating properties. Multi-axis deep hole drilling services produce components like combine harvester hydraulic manifolds with ±0.02mm tolerances, ensuring leak-free operation under 300+ bar pressures.

The shift toward precision agriculture demands materials like C83600, red brass for fertilizer injection nozzles, and electroless nickel coatings to resist acidic corrosion from ammonium nitrate solutions.

Material Selection: Balancing Wear Resistance and Machinability

Material | Key Metrics | Agricultural Applications | Limitations |

|---|---|---|---|

280 MPa UTS, 20% Pb for chip control | Fertilizer valve bodies | Limited to <120°C operating temperatures | |

330 MPa UTS, 0.1 CoF under dry conditions | Pivot bushings for harvesters | Requires oil-impregnation for dusty environments | |

470 MPa UTS, 35% Zn content | Irrigation system fittings | Susceptible to dezincification in acidic soils | |

585 MPa UTS, 11% Al for wear resistance | Plowshare mounting sleeves | High tool wear during drilling |

Material Selection Protocol

High-Pressure Hydraulic Systems

Rationale: C83600’s 280 MPa tensile strength and 20% lead content enable drilling Ø3mm × 150mm (L/D 50:1) fertilizer injection nozzles at 0.1mm/rev feed rates without chip welding.

Validation: ISO 10763 hydraulic pulse testing confirms 10⁶ cycles at 350 bar with <0.1% flow deviation.

Abrasive Soil Environments

Logic: C95400 aluminum bronze’s 400 HB hardness withstands 50 mg/m³ silica dust concentrations, outperforming steel in subsoiler components.

Cost-Driven High-Volume Parts

Strategy: C36000 brass allows drilling 500+ irrigation fittings per tool life via thread whirling at 3,000 RPM, reducing costs by 40% vs bronze.

CNC Drilling Process Optimization

Process | Technical Specifications | Applications | Advantages |

|---|---|---|---|

Ø10-80mm, 0.03mm/m taper, 200 psi coolant | Combine harvester hydraulic blocks | Achieves Ra 1.6μm in 30:1 L/D holes | |

Ø2-15mm, 0.01mm circularity, 1,200 RPM | Pesticide spray nozzles | Maintains ±0.5° angular accuracy | |

20kHz vibration, 0.05mm chip thickness | Aluminum bronze wear sleeves | Reduces tool wear by 60% | |

0.3mm retract intervals, 0.15mm/rev feed | Brass irrigation fittings | Prevents chip entanglement in deep holes |

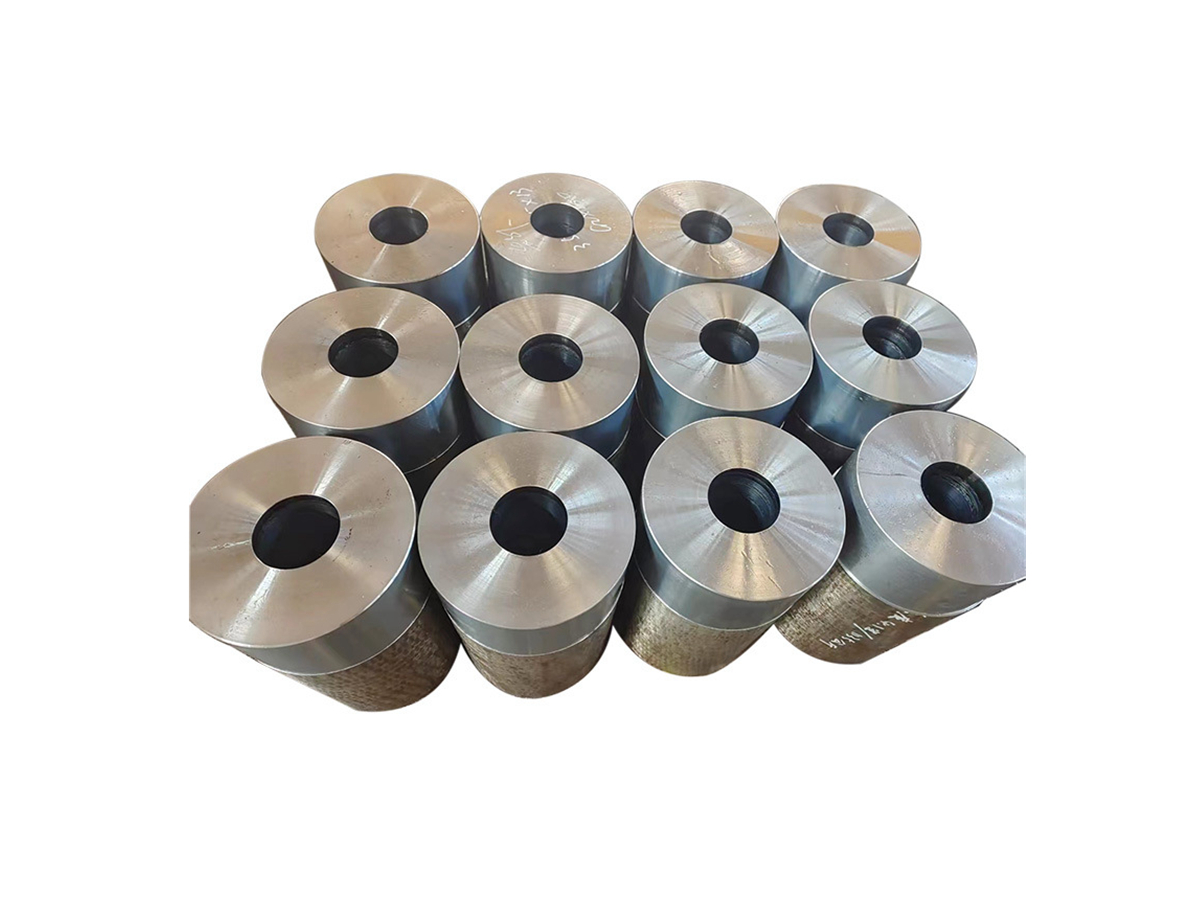

Case Study: Fertilizer Injection Nozzle Production

Component: John Deere ExactApply Nozzle Body

Material: C83600 leaded brass (UNS C83600)

Drilling Process: Gun drilling Ø3mm × 150mm (L/D 50:1)

Parameters:

Tool: Solid carbide gun drill with TiAlN coating

Speed: 1,500 RPM

Feed: 0.08 mm/rev

Coolant: Water-soluble emulsion (7% concentration)

Result:

Straightness: 0.015mm/m (ISO 1101)

Surface Finish: Ra 0.8μm (ASME B46.1)

Cycle Time: 2.2 minutes/nozzle

Surface Engineering: Combatting Agricultural Corrosion

Treatment | Technical Parameters | Agricultural Benefits | Standards |

|---|---|---|---|

25μm thickness, 0.12 CoF, <5% porosity | Self-lubricating pivot joints | ASTM B733 | |

0.5-1.5μm coating weight, 500h salt spray resistance | Corrosion protection for brass fittings | MIL-DTL-5541 | |

150μm thickness, >1,000 HV | Erosion protection in soil-engaging parts | ISO 2063 | |

Nitric acid 30%, 20min immersion | Prevents dezincification in acidic soils | ASTM B154 |

Coating Selection Logic

Fertilizer Systems: Electroless Ni-PTFE withstands pH 2-12 chemical exposure while maintaining 0.12 CoF.

Irrigation Components: Alodine chromate conversion coating passes 1,000h salt spray per ASTM B117.

Tillage Tools: Thermal spray aluminum provides 10x better erosion resistance than uncoated bronze.

Quality Control: Agricultural Machinery Standards

Stage | Critical Parameters | Methodology | Equipment | Standards |

|---|---|---|---|---|

Material Certification | Cu/Zn/Pb ratio ±0.5% | XRF spectroscopy | Olympus Vanta Element | ASTM B271 |

Dimensional Inspection | Hole straightness ±0.02mm/m | Laser-guided bore scope | Keyence IM-8000 | ISO 1101 |

Pressure Testing | 2x working pressure for 5min | Hydraulic test bench | Maxpro 600 bar system | ISO 10763 |

Wear Analysis | Volume loss <0.1mm³ after 100km soil contact | Pin-on-disk tribometer | Bruker UMT TriboLab | ASTM G99 |

Certifications:

ISO 9001:2015 for agricultural component manufacturing

AGCO Q+ supplier certification

Industry Applications

Tractor Hydraulic Manifolds: C83600 brass with BTA-drilled Ø12mm × 400mm channels.

Grain Auger Bearings: C93200 bronze bushings with electroless Ni-PTFE coating.

Sprayer Nozzles: C36000 brass gun-drilled to Ø0.5mm (Ra 0.4μm).

Conclusion

Precision deep hole drilling services enable agricultural machinery manufacturers to achieve 50:1 L/D ratios in brass and bronze, reducing component failures by 70% in abrasive environments. Our ISO 9001-certified processes ensure compliance with AGCO and John Deere supplier standards.

FAQ

Why choose C83600 brass for fertilizer systems?

How does ultrasonic drilling improve bronze machinability?

What coatings prevent dezincification in acidic soils?

Can gun drilling achieve Ø0.5mm holes in brass?

How to validate wear resistance for plow components?