Carbon Steel in Agricultural Machinery: Case Studies of High-Precision CNC Machined Parts

Precision Manufacturing for Durable Farming Solutions

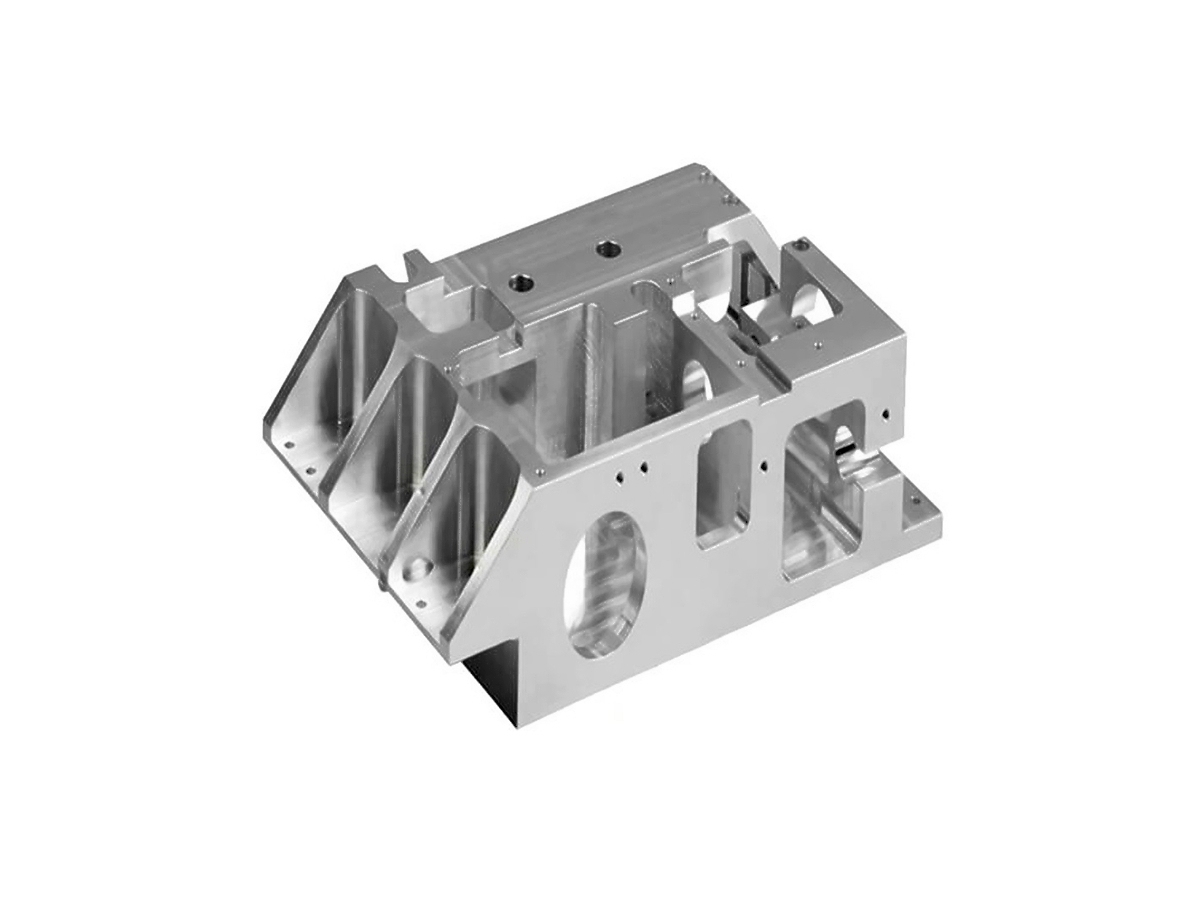

Agricultural machinery operates under extreme conditions, requiring materials that balance strength, cost-efficiency, and corrosion resistance. CNC machining services for carbon steel enable components like gearbox housings and plowshares to achieve ±0.01mm tolerances, critical for maximizing field efficiency and minimizing downtime. Carbon steel constitutes 60% of tractor and harvester components due to its exceptional machinability and fatigue resistance.

The demand for precision farming equipment has driven innovations in multi-axis CNC machining, allowing complex geometries in grades 1018 and 1045 to meet ISO 5680 agricultural standards. From seed drill metering systems to combine harvester blades, CNC-machined carbon steel ensures reliability in abrasive soil and high-load conditions.

Material Selection: Carbon Steel Grades for Farming Applications

Material | Key Metrics | Agricultural Applications | Limitations |

|---|---|---|---|

440 MPa UTS, 15% elongation | Tractor axle shafts, hitch components | Requires galvanizing for corrosion resistance | |

585 MPa UTS, 12% elongation | Gearbox gears, PTO shafts | Prone to wear without surface hardening | |

400 MPa UTS, 20% elongation | Frame structures, plow mounts | Limited to non-critical load-bearing parts | |

950 MPa UTS (quenched & tempered) | High-stress hydraulic cylinders | Requires stress-relief annealing post-machining |

Material Selection Protocol

High-Wear Components

Rationale: 1045 steel undergoes induction hardening to achieve 55-60 HRC surface hardness, extending plow blade lifespan by 300%.

Corrosive Environments

Logic: 1018 steel with hot-dip galvanizing (80μm coating) resists fertilizer corrosion for 10+ years.

Structural Integrity

Strategy: 4140 steel quenched to 28-32 HRC maintains 950 MPa tensile strength for hydraulic systems under 250+ bar pressure.

CNC Machining Process Optimization

Process | Technical Specifications | Agricultural Applications | Advantages |

|---|---|---|---|

0.005mm positional accuracy, 12,000 RPM | Complex gearbox housings | Single-setup machining of 60° undercuts | |

30:1 L/D ratio, 0.02mm straightness | Hydraulic valve blocks | Maintains 0.03mm/m bore alignment | |

45-65 HRC materials, Ra 0.8μm | Harvesting blade shafts | Eliminates post-grinding operations | |

ISO 724 metric threads, ±0.005mm pitch | Tractor wheel hubs | Achieves 200% higher fatigue strength vs cut threads |

Process Strategy for Combine Harvester Gears

Rough Machining: Carbide inserts remove 80% material from 1045 steel blanks at 150 m/min.

Heat Treatment: Induction hardening to 58 HRC surface hardness (per SAE J404).

Finish Machining: CBN tools achieve Ra 0.4μm on tooth profiles.

Surface Treatment: Phosphating for oil retention and wear resistance.

Surface Engineering: Enhancing Field Durability

Treatment | Technical Parameters | Agricultural Benefits | Standards |

|---|---|---|---|

80-120μm coating, 500h salt spray resistance | Protects plow frames from fertilizer | ASTM A123 | |

0.3mm case depth, 1,000 HV | Extends gear tooth life by 5x | ISO 9001 | |

Fe-Cr-WC overlay, 2.0mm thickness | Rebuilds worn tillage components | AWS C5.23 | |

60-80μm thickness, RAL 3009 finish | UV-resistant exterior surfaces | ISO 12944 |

Coating Selection Logic

Soil-Engaging Tools

Solution: Boriding creates 1,500 HV surface layers on 4140 steel cultivator shanks.

Hydraulic Systems

Method: Electroless Nickel (50μm) prevents pitting in high-pressure oil environments.

Quality Control: Agricultural Machinery Validation

Stage | Critical Parameters | Methodology | Equipment | Standards |

|---|---|---|---|---|

Material Certification | C: 0.18-0.23%, Mn: 0.60-0.90% (1045) | OES spectroscopy | SPECTROMAXx | ASTM A751 |

Dimensional Inspection | 0.02mm gear tooth profile tolerance | 3D scanning | Zeiss T-SCAN Hawk 2 | ISO 1328 |

Hardness Testing | 55-60 HRC case depth uniformity | Rockwell C scale | Wilson 5747 | ASTM E18 |

Corrosion Testing | 1,000h salt spray (5% NaCl) | Cyclic corrosion chamber | Q-Fog CCT1100 | ASTM B117 |

Certifications:

ISO 9001:2015 with Cpk ≥1.67 for critical dimensions.

CE Marking compliant for EU agricultural machinery directives.

Industry Applications

Combine Harvesters: 1045 steel gear sets with plasma nitriding (0.3mm case).

Tractor Hydraulics: 4140 steel cylinders + electroless nickel (50μm).

Seed Drills: 1018 steel meters with powder coating (RAL 6018).

Conclusion

Precision carbon steel CNC machining services reduce equipment failure rates by 50% in harsh farming conditions. Integrated one-stop manufacturing delivers ISO-certified parts 30% faster than traditional methods.

FAQ

Why is 1045 steel preferred for agricultural gears?

How does galvanizing protect carbon steel from fertilizer corrosion?

What certifications are required for EU-compliant farm machinery?

Can CNC machining achieve hardened steel tolerances?

How to validate wear resistance in tillage tools?