CNC Turning and Grinding Solutions for 1045 Steel Motor Spindles in Agricultural Machinery

CNC Machining of Agricultural Motor Spindles: Durability and Precision Under Load

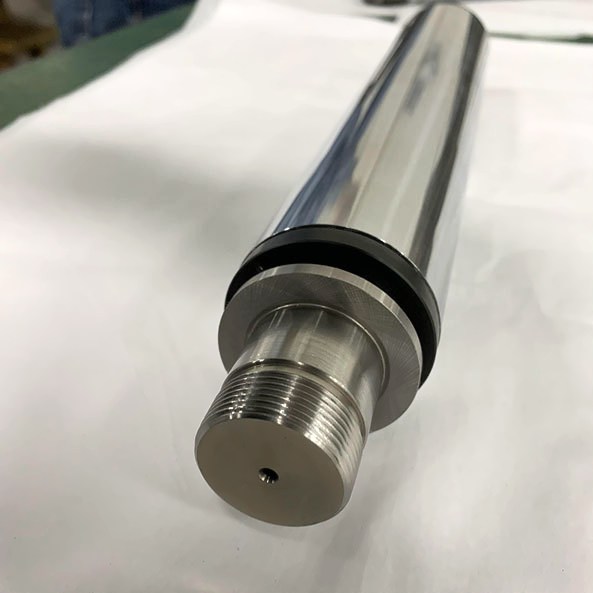

Motor spindles in agricultural machinery are exposed to harsh operating conditions, including shock loads, debris, variable speeds, and extended cycles. These rotating components demand exceptional mechanical strength, roundness, and surface integrity to ensure system uptime and operational reliability. At Neway, we deliver CNC turning and CNC grinding solutions specifically for agricultural machinery applications, machining 1045 steel motor spindles with integrated heat treatment to enhance wear and fatigue resistance.

Our motor spindle shafts are manufactured to precise tolerances, hardened for long-term strength, and balanced for rotational stability in high-torque drive systems.

Why 1045 Steel Is Ideal for Agricultural Motor Spindles

Medium-Carbon Strength with Hardenability

1045 steel is widely used for agricultural shafts due to its high tensile strength (≥620 MPa), toughness, and responsiveness to induction hardening. It strikes a balance between machinability and durability, making it suitable for spindles that encounter repeated bending and torsional loads.

Dimensional Stability After Heat Treatment

1045’s uniform grain structure and low alloy content ensure excellent size retention after thermal processing. This is critical for achieving tight tolerances in grinding and for compatibility with bearing housings or spline fits.

CNC Turning and Grinding Process for Motor Spindles

CNC Turning for Roughing and Geometry Definition

Our high-rigidity lathes perform multi-stage turning to define shaft geometry including:

Bearing journals

Threaded ends

Tapered or stepped profiles

Retaining shoulders

Turning achieves tolerances of ±0.01 mm and Ra ≤ 3.2 µm, preparing the shaft for final finishing.

CNC Grinding for Journal Accuracy and Surface Finish

After heat treatment, CNC grinding is used on critical journal zones to achieve:

Diameter tolerance: ±0.005 mm

Roundness: ≤ 0.01 mm

Surface finish: Ra ≤ 0.4 µm

These features ensure stable rotation, reduced friction, and extended bearing life even in contaminated field environments.

Heat Treatment for Wear and Fatigue Performance

1045 spindles are induction hardened to HRC 50–55 with case depths of 1.0–1.5 mm. This hard outer layer resists abrasion and brinelling, while the ductile core maintains resistance to impact and deflection.

Controlled hardening zones around journals

Post-treatment tempering to prevent brittleness

Minimal distortion due to controlled quenching

Quality Assurance and Measurement Control

CMM validation of shaft geometry and runout

Hardness tested with Rockwell C method at key zones

Roughness testing for each ground surface

Full traceability with MTCs, heat treatment charts, and inspection reports

Why Choose Neway for CNC Machined Motor Spindles

Expertise in 1045 steel machining for dynamic shaft components

Complete in-house heat treatment and grinding for process control

One-stop CNC manufacturing with scalable volumes and rapid response

Mass production support with quality consistency for agricultural OEMs

CNC Services for Agricultural Shaft Manufacturing Projects

Neway delivers dependable CNC solutions for motor spindle production in agricultural powertrains and implements. Our services include:

CNC Turning and Grinding: Full-profile accuracy for long shafts and journal finishes

1045 Steel CNC Machining: Ideal for fatigue-resistant, hardened drive spindles

End-to-End Production Services: From prototyping to production with integrated inspection and documentation

We help agricultural machinery manufacturers reduce downtime, increase shaft lifespan, and streamline supply chain logistics.

FAQs

What is the typical case hardness for induction-hardened 1045 motor spindles?

How is shaft straightness and runout controlled post-heat treatment?

Can Neway produce large-diameter or long motor spindles for combines or tractors?

What inspection documentation is included with each batch of spindle shafts?

Do you provide both prototype and mass production services for agricultural drive shafts?