CNC Turning and Grinding Solutions for 1040 Steel Motor Shafts in Automotive Applications

CNC Machining of Automotive Motor Shafts: Precision, Strength, and Performance

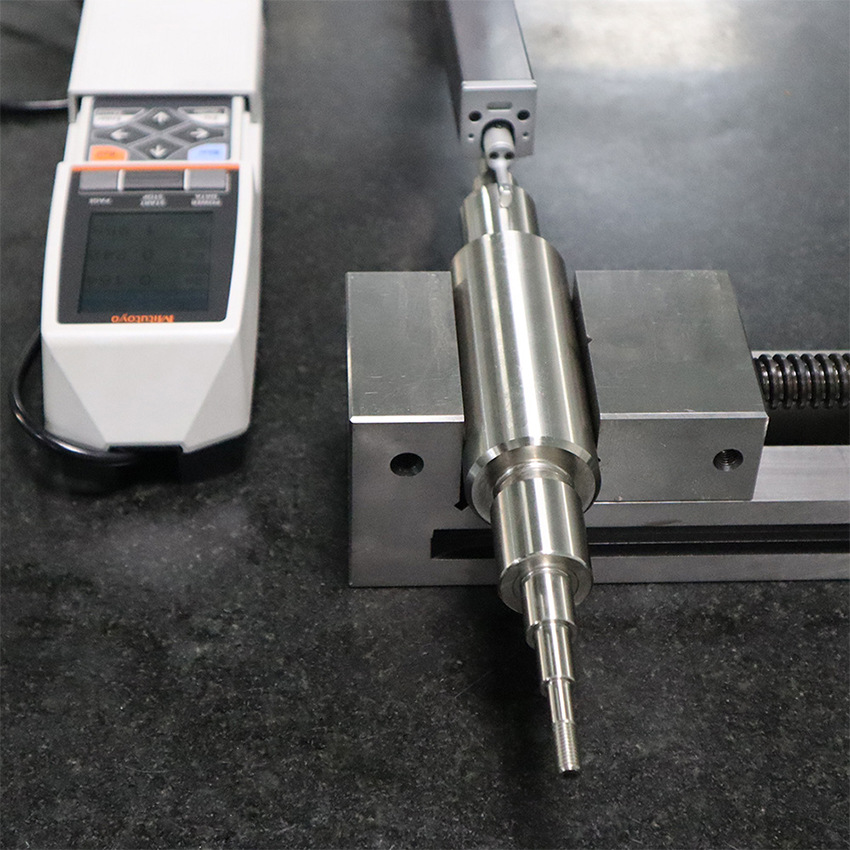

Motor shafts are critical drivetrain components in modern vehicles, transmitting torque and rotation under dynamic load conditions. These components require exceptional roundness, straightness, surface integrity, and fatigue strength. At Neway, we manufacture custom motor shafts using CNC turning and CNC grinding, combined with heat treatment processes to optimize durability for automotive applications.

Machined from 1040 medium-carbon steel, our motor shafts deliver the hardness, straightness, and wear resistance demanded by electric motors, internal combustion engines, and transmission systems.

Why 1040 Steel Is Chosen for Automotive Shaft Components

Excellent Balance of Strength and Machinability

1040 steel offers a tensile strength of ~620 MPa and responds well to heat treatment for improved surface hardness. It delivers better toughness and fatigue resistance than low-carbon grades while maintaining favorable machinability for shaft production.

Ideal for Induction Hardening and Precision Grinding

Its uniform microstructure and carbon content make 1040 suitable for induction or flame hardening. Post-hardening, it retains dimensional stability, enabling tight-tolerance grinding of bearing journals, press-fit zones, and spline interfaces.

CNC Turning and Grinding Process for Motor Shafts

CNC Turning for Pre-Forming and Feature Machining

Turning is used to generate the shaft’s raw profile, including journals, keyways, chamfers, and thread zones. Our high-rigidity CNC lathes maintain:

Diameter tolerance: ±0.01 mm

Concentricity: ≤0.02 mm across multiple shaft features

Surface finish: Ra 1.6–3.2 µm (pre-grind)

CNC Grinding for Finish Accuracy and High-Speed Stability

After heat treatment, critical surfaces are ground to final specification using precision CNC grinding. This includes:

Journal diameters with tolerance: ±0.005 mm

Surface finish: Ra ≤ 0.4 µm for bearing zones

Roundness and straightness: ≤ 0.01 mm across total shaft length

These properties ensure vibration-free rotation, low friction, and long service life under high RPM conditions.

Heat Treatment for Strength and Wear Resistance

The 1040 shafts undergo induction hardening to a case depth of 0.8–1.2 mm, achieving:

Surface hardness: HRC 50–55

Core toughness retained for impact loading

Enhanced wear resistance in sliding or rotational interfaces

Each batch is validated for hardness uniformity and distortion control prior to grinding.

Quality Control and Compliance

CMM and dial test indicators used to check runout, concentricity, and diameters

Surface roughness verified with calibrated profilometers

Hardness testing (Rockwell C scale) after heat treatment

Certification includes COC, material traceability, and heat treatment records

Why Choose Neway for CNC Machined Motor Shafts

Specialization in CNC machining of carbon steel shaft components for high-performance systems

Integrated heat treatment and grinding services for wear-critical applications

Mass production capabilities with tight process control and automotive documentation

One-stop CNC service from raw material to delivery-ready parts

CNC Services for Automotive Motor Shaft Manufacturing

Neway supports OEMs and tier suppliers with complete CNC solutions for motor shaft manufacturing. Our key offerings include:

CNC Turning and Grinding: Achieving high accuracy, straightness, and balance for rotating shafts

1040 Steel CNC Machining: Optimized for strength, hardness, and dimensional control

In-House Heat Treatment: Ensuring reliable hardening without warping

Choose Neway for reliable, scalable production of precision motor shafts tailored to demanding automotive requirements.

FAQs

What surface hardness can be achieved for heat-treated 1040 motor shafts?

How do you ensure concentricity and straightness after heat treatment?

What is the typical runout control standard for automotive shaft components?

Can Neway provide prototype and mass production volumes for motor shafts?

Are hardness and dimensional test reports included with delivery?